Fuel pressure is way too low.

Fuel Presure

Key on, engine off .................... 414-448 kPa (60-65 psi)

Engine running .................... 414-448 kPa (60-65 psi)

You need to replace the fuel pump to get the pressure correct.

https://www.2carpros.com/articles/how-to-replace-an-electric-fuel-pump

Roy

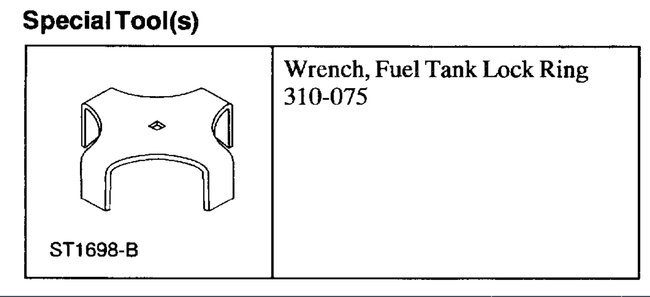

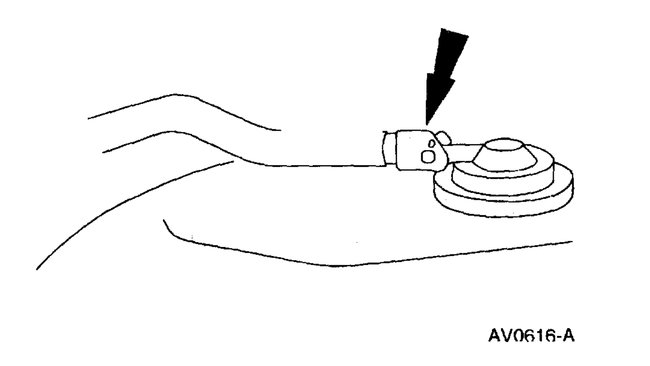

Wrench, Fuel Tank Lock Ring

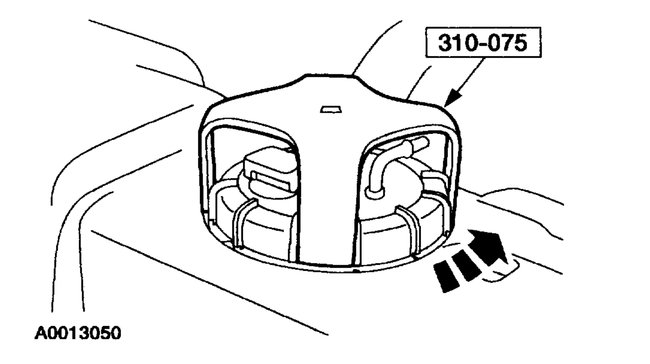

imageOpen In New TabZoom/Print

SPECIAL TOOL(S)

REMOVAL

1. Remove the fuel tank.

2. Clean the area around the fuel pump mounting flange.

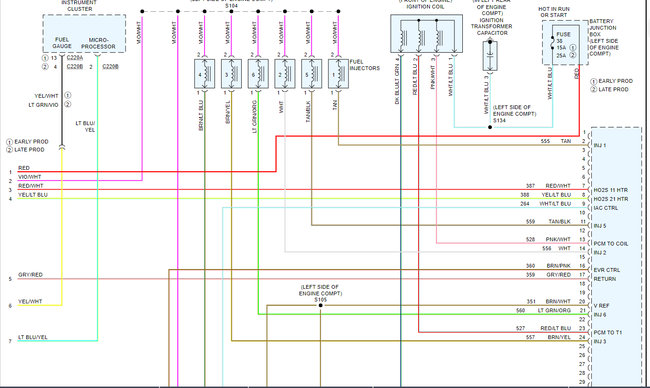

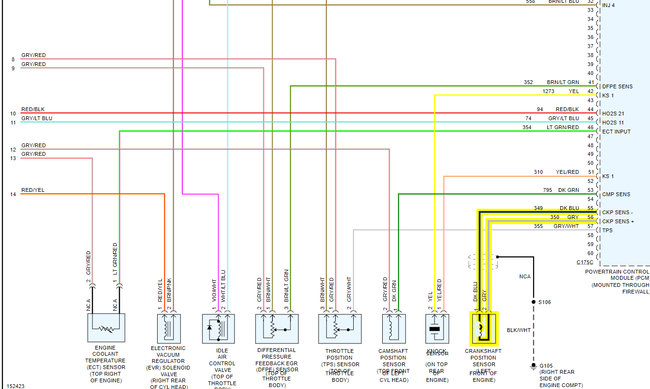

imageOpen In New TabZoom/Print

3. Using the special tool, remove the fuel tank pump assembly locking retainer ring.

4. Remove the fuel pump assembly.

CAUTION: The fuel pump assembly must be removed and handled carefully to avoid damage to the float arm and filter.

5. Remove and discard the fuel pump mounting gasket.

Removal

Warning:

Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel-related component. Highly flammable mixtures are always present and may be ignited, resulting in possible personal injury.

fuel in the fuel system remains under high pressure even when the engine is not running. Before repairing or disconnecting any of the fuel lines or fuel system components, the fuel system pressure must be relieved to prevent accidental spraying of fuel, causing personal injury or a fire hazard.

1. Relieve the system pressure.

imageOpen In New TabZoom/Print

2. Disconnect the fill pipe main hose.

Loosen the fill pipe main hose clamp.

Disconnect the fill pipe main hose from the main fill tube.

3. Drain the fuel tank.

imageOpen In New TabZoom/Print

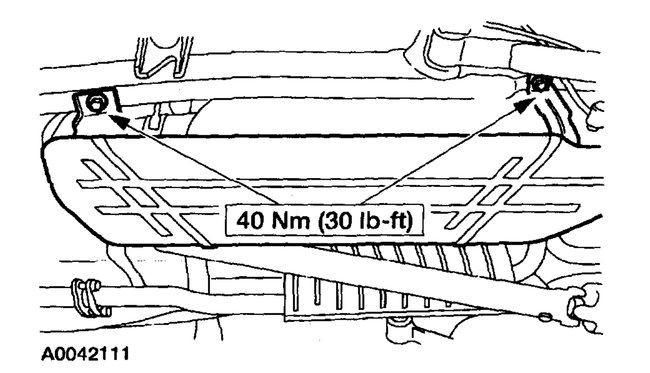

4. Remove the four bolts (two each side) and remove the skid plate, if equipped.

5. Support the fuel tank.

imageOpen In New TabZoom/Print

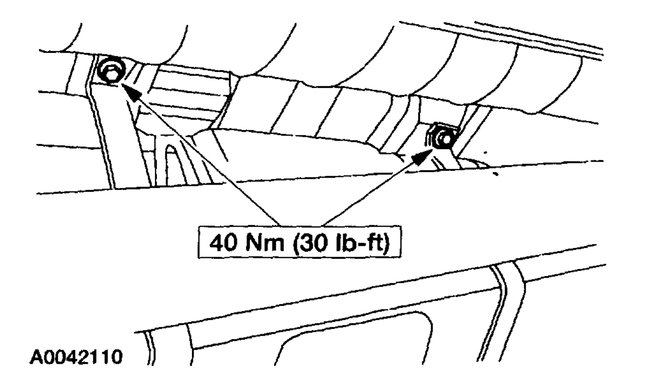

6. Remove the bolts and pivot the fuel tank support straps away from the fuel tank.

imageOpen In New TabZoom/Print

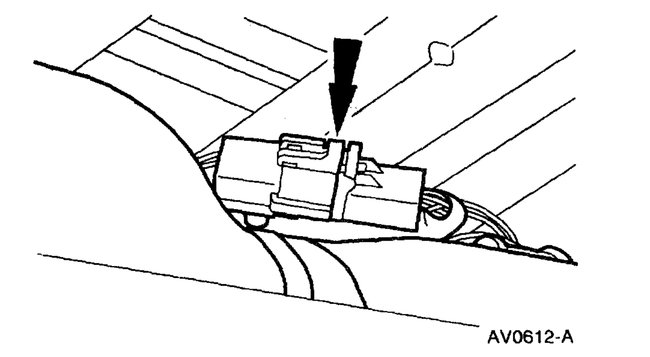

7. Disconnect the fuel pump connector.

Lower the fuel tank slightly.

Disconnect the fuel pump connector.

imageOpen In New TabZoom/Print

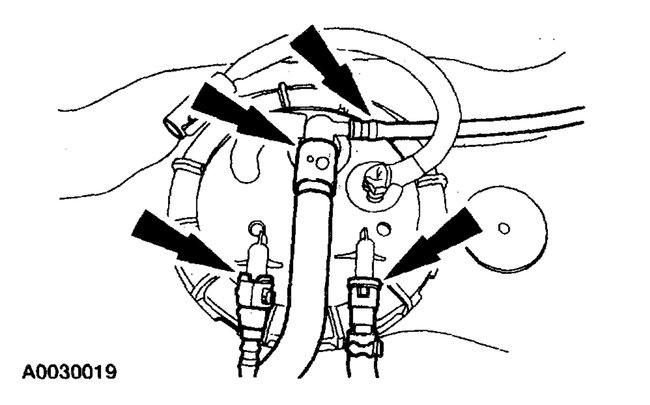

8. Disconnect the fuel supply and return line push-connect fittings, the vapor tube and fill tube vent hose fittings at the fuel pump.

imageOpen In New TabZoom/Print

9. Disconnect the vapor line fitting at the rear of the fuel tank.

10. Lower the fuel tank.

INSTALLATION

1. To install, reverse the removal procedure.

Images (Click to make bigger)

Thursday, November 12th, 2020 AT 2:36 PM