Over the past 20 years at 2CarPros we have identified the top problems that are easily fixed. This guide can save you a trip to the repair garage or calling a tow truck and get you back on the road quickly. Before beginning any repairs, please ensure you're equipped with gloves and safety eyewear for protection. Please keep the parking brake on so the car doesn't move. We have categorized common vehicle engine starting problems by symptoms for easy navigation.

Turn the Key and Nothing Happens

1. Poor Battery Connection: Raise the hood to located the battery, it should be either a the right or left front or right rear of the engine compartment. Some cars will have the battery in the trunk or under the rear seat. Once located and while wearing gloves/protective eyewear inspect the positive battery cable terminal for corrosion and try to move it. If the terminal is corroded or loose, this can be the problem. To repair the issue clean or tighten the battery cables, repeat this process for the negative cable. (Do not pound/strike on the battery with a shoe or other means). Wash your hands immediately anytime you work with a battery.

2. Weak/Old Battery: This issue will present itself when you notice the dash lights will not come on, or the dash lights go out when the key is turned, or the starter is producing a machine ticking or ratcheting kind of sound. It is common for the battery to go bad every four to five years, this is an easy repair which can be done with everyday tools. Please use our battery replacement guide, you can get a new battery from the local auto parts store such as AutoZone.

3. Neutral Safety Switch: This applies to automatic, manual, or paddle shift transmission cars. The neutral safety sensor/switch feeds data to the engine computer (PCM) and will allow the engine to crank over and start and run safely. To check this, turn the ignition switch/system on, then move the gear selector to the natural gear or position and then try to start the engine. If the engine starts, you know the neutral safety switch has gone bad and needs replacement. For standard transmission cars pump the clutch pedal down five times, holding it down on the last while making sure the floor mat is not under the pedal. If the engine starts the neutral safety sensor needs to be adjusted or replaced.

4. Bad Starter Motor: If when you turn the ignition key or push the start button here hear a signal "click" you may have a starter motor that is beginning to go out. To check this you can use a metal implement such as a long standard screwdriver or socket extension to tap o the starter housing. This can get the starter to work again because the vibration and temporarily fix the internal connection at the armature brushes.

Watch the Video!

Please watch this video of the repair being done to glean additional helpful information.

The Engine is Cranking Over But Will Not Run

In the following section we address the simply fixes for an engine that is cranking over but will not run.

Lets Jump In!

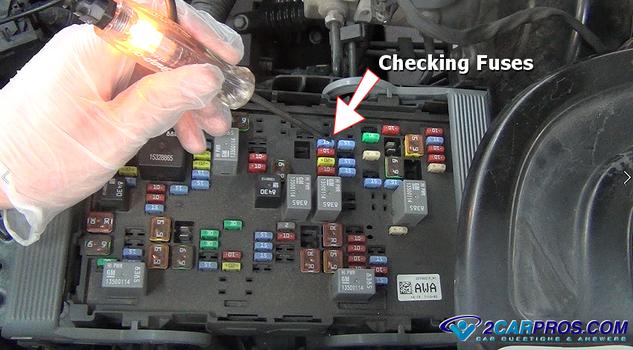

1. Before going any further down the troubleshooting tree, it is best to check the fuses, this is easy to do and can be done in just a few minutes by using a test light or visual inspection. The fuse panel will be either under the hood, or inside the vehicle under the dashboard. Once you have found the panel, remove the lid, the fuses should be clearly marked, simply turn the ignition system on and begin the inspection or testing.

2. When you turn the ignition key on, or to the crank position does the security light flash? Each manufacturer disables the engine in different ways while in security mode and occasionally the system can become confused due to a glitch or a procedural error, in either case the security system must be reset.

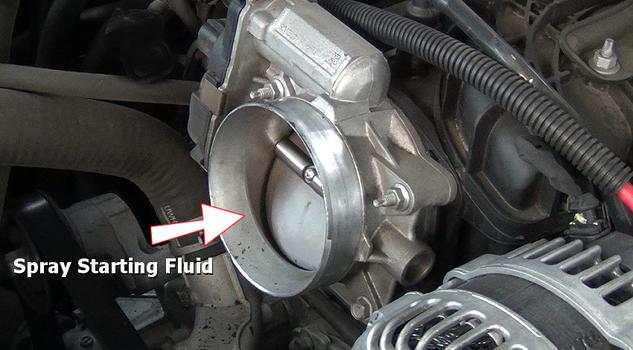

3. It takes three things to make an engine run, fuel, ignition and compression, start by removing the air intake boot or tube to expose the throttle body, then spray starting fluid which you can get at the auto parts store. Turn the ignition system on and have a helper hold the throttle bore open by pressing down on the gas pedal. This will open the butterfly valve inside the throttle body so you can spray the starting fluid inside. Then, stand back and have a helper crank the engine over while holding the throttle open a little. If the engine starts, you know the problem is fuel related such as your out of gas, a fuel pump failure or fuel pump relay has shorted out.

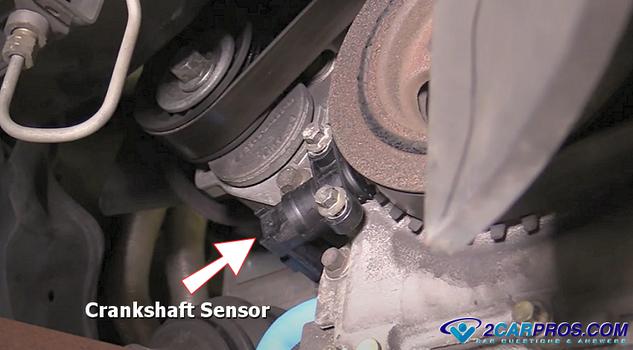

4. If the engine does not start with starting fluid, you need to check for ignition spark by removing the ignition coil or spark plug wire and insert a test light into the boot, crank the engine over and check for spark. If no spark is observed, the most popular reason is a failed crankshaft position sensor which is located near the engine crankshaft, at the rear (bell housing), middle (block) or front by the water pump, and is pretty easy to change in most cases.

5. Crank the engine over and listen to how it sounds, does it sound funny or faster than usual? This can mean the timing belt or chain has failed causing the engine to have no compression. Perform a compression test to confirm the failure, observing the engine camshaft rotation through the oil filler cap on the valve cover will also confirm the issue, (camshaft not turning while the engine is cranking over).

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Conclusion

These are the most common problems a car engine can have when it will not start. There are many other reasons an automotive engine will no run but we have outlined the most common problems. If you have question or need help please ask one of our experts we are happy to help.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. Please visit our 2CarPros YouTube Channel for additional car repairs.