The first thing in your favor is you don't have a Nippendenso starter. Yours uses a standard solenoid bolted to the starter motor, and I haven't heard of any common problems. The second thing is you replaced the starter already, and the chance of having two bad ones is pretty unlikely. That's assuming you installed a rebuilt starter and not a used one. That just leaves the cables and connections, and if I'm right, we'll find it with the voltmeter.

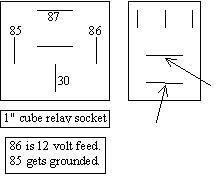

We could measure "voltage drops", but in this case it will be just as easy to simply measure the voltages at various points. The hardest part of this test is going to be catching the problem while it's occurring, and to keep it in the bad state so it can be diagnosed. You may want to wait until the problem acts up more often. One way to start is with a helper turning the ignition switch. The problem is the engine is going to want to start, and if you cycle the switch fast enough, many of the models will only let you do that three times before you have to wait a while. A better trick is to pop the cover off the starter relay and squeeze the contact, or you can remove the relay completely and use a jumper wire or stretched-out cotter pin to jump terminals 30 and 87 together. The advantage to the cotter pin is if you can catch it acting up, you can leave that in place, then do the testing without a helper. You can also do the following procedure when the starter is working properly, but it's irrelevant because the engine is going to start right away, and the readings will have little meaning. It will give you a feel for doing the procedure though.

Once you have the problem occurring, starter solenoid engaged, but the starter isn't cranking the engine, place the voltmeter probes right on the battery posts, (not the cable clamps attached to them. For this example, lets say you find 12.0 volts. Now move the positive probe from the post to the cable clamp, then move the negative probe to that clamp. You should still read 12.0 volts. When the starter is cranking the engine, you're allowed 0.2 volts less at each clamp, actually, each mechanical connection, but that is next to impossible to measure this way.

These guides can help us fix it

https://www.2carpros.com/articles/starter-not-working-repair

and

https://www.2carpros.com/articles/car-battery-load-test

Check out the diagrams (Below). Please let us know what happens.

Image (Click to make bigger)

Sunday, August 24th, 2014 AT 10:38 PM