Good afternoon,

I attached the test for the mass air flow sensor for you to view.

https://www.2carpros.com/articles/how-a-mass-air-flow-sensor-works-maf

https://www.2carpros.com/articles/how-to-replace-a-mass-air-flow-sensor-maf

https://www.2carpros.com/articles/how-to-check-wiring

As far as the leads, you can go to Harbor Freight and they will have longer leads for your voltmeter.

https://www.harborfreight.com/search?q=voltmeter%20leads

Roy

Note:

The best way to resolve a Code 45 or drivability incident is to carefully go through ALL the steps contained within this bulletin.

A poor connection for either the MAF's ground or signal wire can cause a false high MAF's voltage reading, this will cause a rich mixture.

NOTE:

All tests should be performed with the engine @ 2000 rpm. Engine temperature should be warm.

1.Gently move the MAF's harness and connector in all directions while observing the engine speed. If the engine speed or engine smoothness changes when the harness connector is moved, the incident may be caused by a poor connection at the connector pins.

2.Gently move the MAF's harness and connector in all directions while observing the ALPHA reading on CONSULT This reading should not change while wiggling the MAF's harness or connector.

If moving the MAF's harness causes a change in the ALPHA reading, then the harness/ connector must be repaired:

A. Disconnect the MAFS connector at the MAFS.

B. Inspect the male pins on the MAF's for corrosion or damage (clean and repair as necessary).

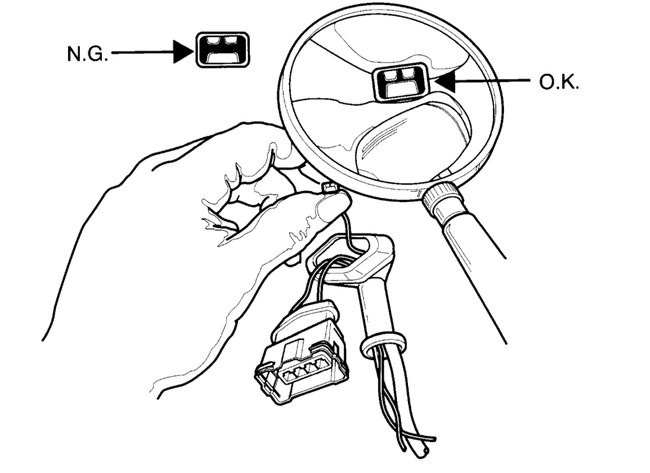

image

C. Remove, inspect, and reinstall one at a time the female pins at the MAF's harness connector. Carefully push the connector and wire out through the back side of the connector. Use a modified Kent-Moore tool J38751-305 (modify by increasing the length of the working end of the tool about 1/4" - this can be done with a grinder or file) Extract the individual pin by releasing the locking tab with the special tool through the recess on the component side of the connector. Inspect the contact surfaces of the pin for any corrosion or damage. The female pins contact force should be checked by sliding the female connector over the appropriate male pin on the MAFS and checking for a snug fit. The contact force can be increased by bending the contact springs toward each other slightly with an appropriate tool.

imageOpen In New TabZoom/Print

D. If any of the pins appear to be damaged, or if the wire is not properly crimped onto the female pin the terminal pin must be replaced. The terminal pin connector P/N is J38751-50. The wire seal P/N is J38751-48. Both parts are available in the Kent Moore terminal repair kit. Crimp and solder the new terminal pin on to the harness wire.

E. After all the female pins have been inspected/repaired, reattach the MAF's connector and perform tests 1 and 2 above to verify repair.

Image (Click to make bigger)

Sunday, December 6th, 2020 AT 11:48 AM