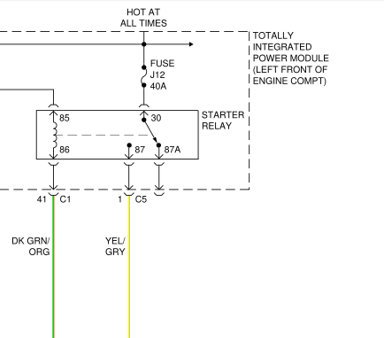

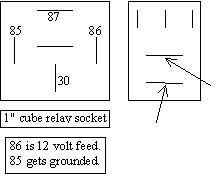

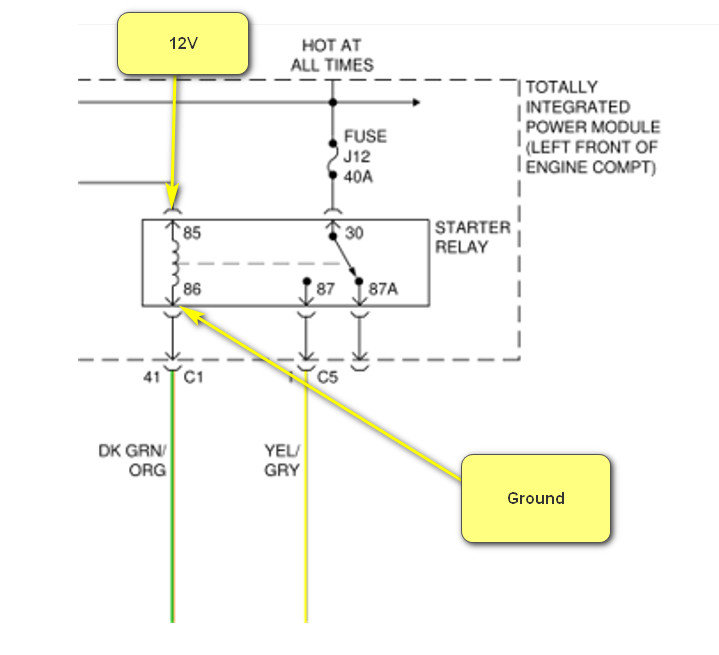

The last diagram is backward. Remember, all relay coils develop a reverse voltage spike when they get turned off, and there's a diode in there to short those spikes out. It is common to not show the diodes as is the case here. Because of that diode, terminals 85 and 86 can't be switched. 12 volts has to come in on terminal 86, and terminal 85 has to get grounded for the relay to energize.

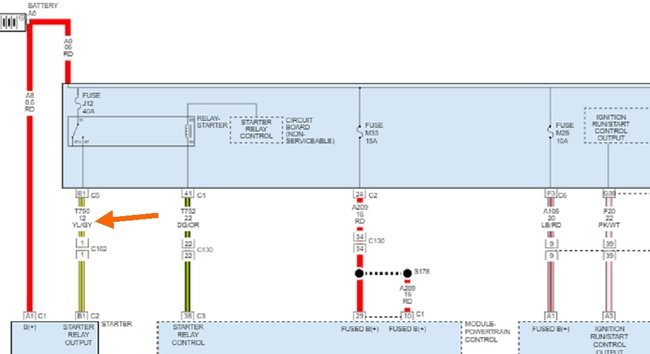

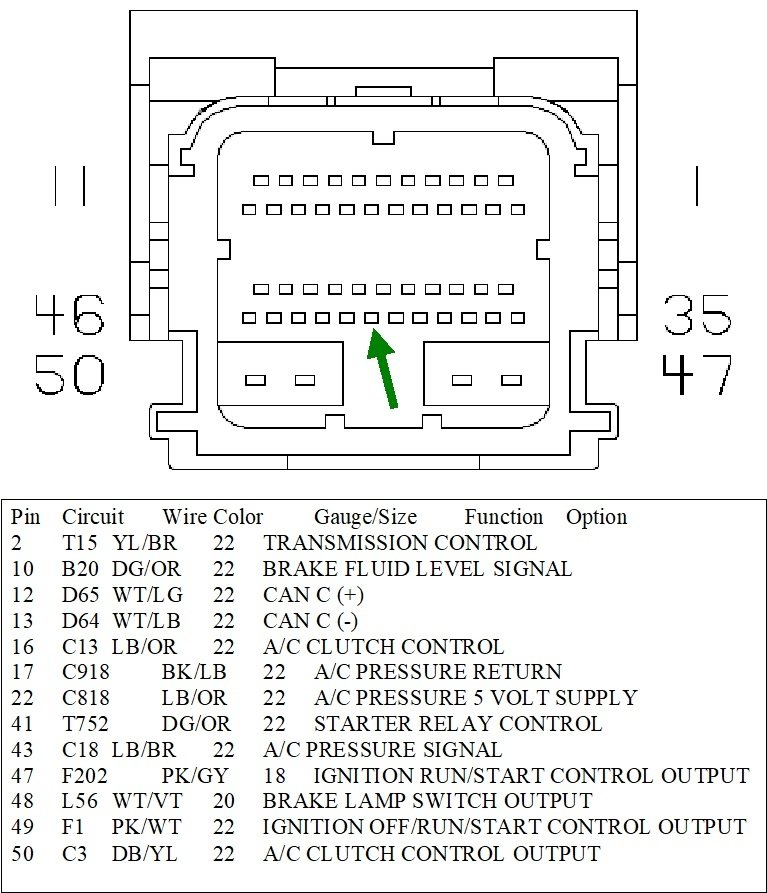

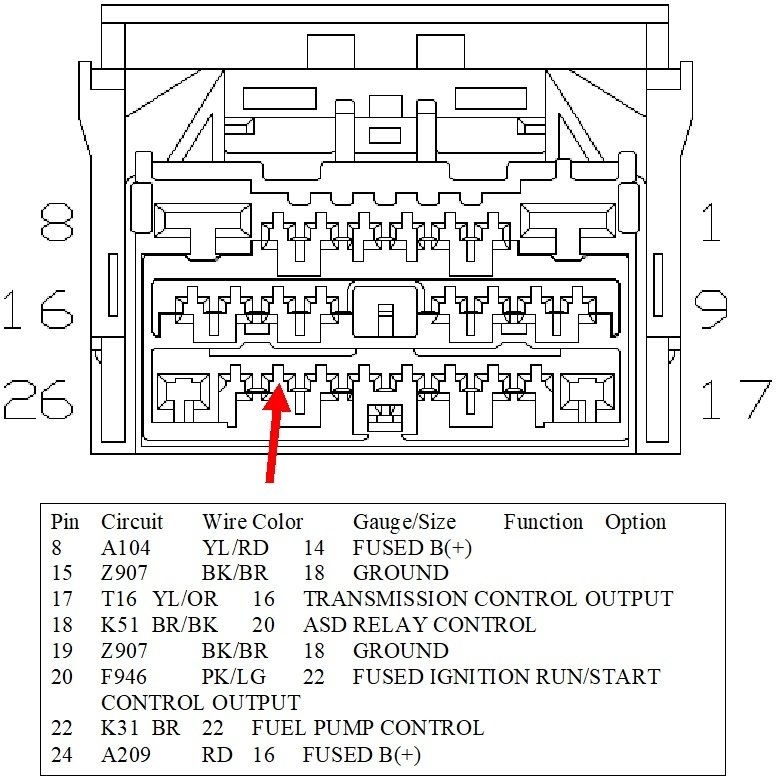

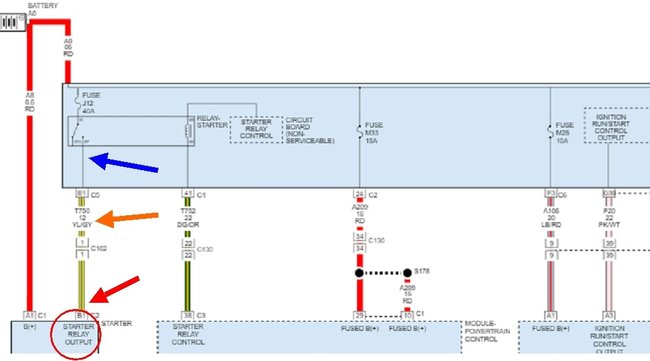

To add to the confusion, we typically draw diagrams to start with the power supplies on top, circuitry in the middle, and grounds at the bottom. Now, with all the computer circuitry, it isn't always practical to do it that way. The 12 volts used to come from the ignition switch. Now it comes from the Engine Computer, (Powertrain Control Module), on the dark green / orange wire. The ground side of the coil is shown at the top in the TIPM. It gets grounded by the "starter relay control" circuitry which takes the place of the neutral safety switch on older models. Once that circuit grounds the relay's coil, the coil is energized. Until that happens, you'll see the 12 volts there that came through the coil from the dark green / orange wire.

Adding wires to the socket so you can take readings with the relay plugged in is how I do it too. Most voltage readings are only valid when the circuit is "complete", meaning intact and current can flow through it. There are plenty of places where people get "wrapped around the axle" and go down the wrong diagnostic path after getting invalid readings from just part of a circuit. One word of warning though. Forcing a fat wire alongside a relay terminal can spread the female terminal in the socket to the point it makes poor or intermittent connection later. This is even more of a problem on GM vehicles. For those, it's better to wrap the wire around the terminal on the relay first, then install the relay that way. Doing it that way puts no wire alongside the terminals so those in the socket can't spread open.

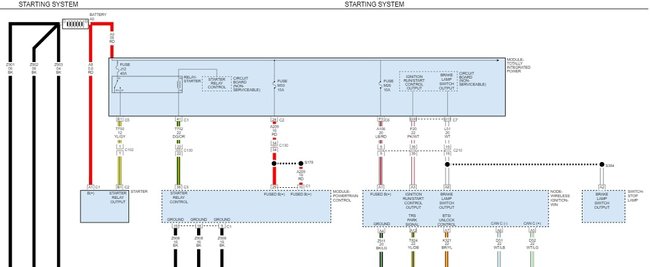

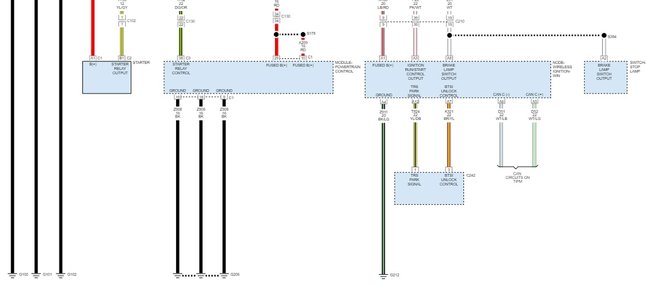

To address your confusion about testing grounds, I added arrows to this diagram. In that ground circuit, ideally there must be no resistance, (0 ohms). In the real world there is always a very tiny amount of resistance in every wire. When current flows through that resistance, it causes some voltage to be "dropped" across it. Most of the time that voltage is too small to measure, and it has no effect on the performance of that circuit. Wire sizes are selected to be as small as possible to save cost, but big enough to not introduce excessive resistance. The voltage dropped is proportional to the current flowing through it, so as current increases, voltage dropped in that wire increases. Unless specified otherwise by the manufacturer, the industry standard is no more than 0.2 volts is allowed to be dropped in that wire.

One of the secrets to this test is the placement of the meter's probes. Wherever you place them, it's between them that is the part of the circuit you're testing. In this diagram, if one probe is placed at the pink arrow, the tiny area below it is not included in the test. That could equate to testing at the end of the ground wire, but not including the screw that attaches it to the body. If under that screw head is where the corrosion / high resistance exists, the voltage drop won't get included in the measurement, so it will be overlooked. For that reason, I like to put one meter probe right on the battery's negative post or cable clamp. If there's a high resistance problem in those other parts of the circuit, it would affect a lot more things with a lot more symptoms. Instead, we can assume those parts are okay, and every high resistance area will be included in the test.

So, if the meter's probe is on the battery's negative post, and the other one is at the blue arrow, the place we'd typically test at, corrosion and the resulting high resistance at the pink arrow will cause a voltage drop when the circuit is energized. That's the other key point I forgot to stress. Current has to be flowing through the resistance for the voltage drop to show up.

Think back to the garden hose. If you start with 50 psi and the nozzle is turned off, you'll have 50 psi all the way up to the nozzle. Now if you stand on the hose and pinch it off 99 percent, you'll still have 50 psi at the nozzle. 0 psi is dropped across the high resistance, (your foot), because no water is trying to flow through that restriction. It isn't until you open the nozzle, (turn on the electrical circuit), that water pressure is dropped across your foot. If 45 psi is dropped across your foot, that leaves just 5 psi to force water to dribble from the opened nozzle. Water flow, (current flow), is reduced to an unusable level by the excessive undesirable resistance.

The next point of confusion is understanding the difference in measuring a voltage "at a point" vs. "Across" something. For this sad example, lets say there's corrosion above the pink arrow that results in a drop of one tenth of a volt. One meter probe is on the battery's negative post. With the other probe, measure at the blue arrow and find 12.0 volts. Next, measure at the pink arrow and find 11.9 volts. Calculating shows there's that 0.1 volt loss. The problem is the meter has a tolerance or accuracy issue where it can be off just a fuzz. With two measurements you have two fuzzes, so in reality you likely have slightly more or less than the 0.1 you calculated. The measurements are taken at two different times a few seconds apart when the battery is slowly running down, or things are turning on or off causing the amount of current to be different between the times the two readings were taken. All of these variables are eliminated when just one reading is taken with one probe at the blue arrow and the other at the pink arrow. Even if current changes or the battery is running down, the variables are eliminated. Just the one reading will show the true voltage drop. 0.1 volts is within the limit and is acceptable.

In the first tests, we took two voltage readings at two points in the circuit, then calculated the voltage drop. At the end, we took just one direct reading across the voltage drop. I should point out too these tests are done to locate areas of undesirable high resistance. Almost all digital meters also measure "Ohms", meaning resistance, directly. The problem is the resistance values can be way too low to measure accurately. It's much more accurate to use these voltage measurements to measure the results of that resistance. Typical meters can measure to the tenth of an ohm, but there can easily be five or more ohms of resistance just in the meter leads themselves. By contrast, a starter motor circuit can be rendered inoperative with as little as a few hundredths of an ohm resistance in the cables. That's way too small to measure, but we can measure the resulting voltage drop. It's with voltage drop tests we always troubleshoot those high-current circuits.

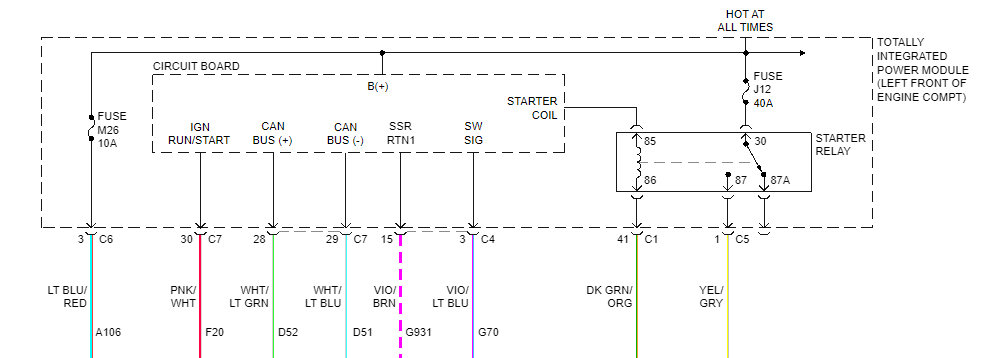

That entire story refers to ground circuits for items such as computer modules, relays, motors, and light bulbs. We want to always see as close to 0.00 volts as possible. Now, we finally get to a different version of grounds. Think back to where you found 4.41 volts on both sides of the relay's coil. We expect to see 12 volts on one side, give or take, and we expect to see 0 volts on the other side, give or take. Relays are pretty forgiving when it comes to that voltage it takes to flip the movable contact. Eight volts is often enough. That means we could have a good three or four volts dropped across undesirable resistances in the circuit and it would still function normally. On older Chrysler products a wire ran from what equates to terminal 85 down to the transmission and its neutral safety switch. The wire, switch, and connector terminals could have a total of a few ohms of resistance, but it wouldn't be enough to prevent the circuit from working. Now the job of the neutral safety switch is being done by the "starter relay control" circuit inside the TIPM, shown at the top of the starter diagram. I can tell you from recent experience that circuit consists of only a relay turned on and off by another computer module. However, a real lot of similar relays on other computers are turned on by their own computer circuits. Those circuits are electrically incapable of drawing the ground side all the way down to 0.00 volts. Most of the time we can't get in there to take measurements, but when we can, it's not uncommon to find well over that magic 0.2 volts. We could even find more than a volt under normal operation. One volt is totally unacceptable in ground wires discussed earlier, but in this case when we talk about ground circuits, we're only interested in whether it's the ground side or the supply side. The exact voltages are of little importance.

That brings me to my last point, finally. That's where you found the 4.41 volts on both sides of the relay's coil. I have a suspicion you found voltages you weren't meant to measure or even know about as they don't help with any diagnostics, and as you've seen, they lead to more confusion. Better to call voltages that low "0 volts" unless you know to expect something else. I think a computer is putting those voltages there, then watching to see if 12 volts shows up from somewhere else, or if one gets shorted to, or "pulled" to ground, meaning near 0 volts. This is better discussed in relation to sensors as it's easier to explain and see. I have diagrams to go further into this if you want me to. To simplify it for now, the computer applies a test voltage to a point, the relay's terminal(s), in this case, through a very large "pull-up" resistor. The resistor is so large electrically that it has almost no effect on the circuit, and it is completely overpowered by the 12 volts and ground when they're present. These pull-up, or test values only show up in a circuit that is not energized or one that has a defect. In this example, he computer knows when it should see 12 volts on one relay terminal and 0 volts on another one, but if it finds 4.41 volts instead, it uses that information to figure out what type of problem is preventing that circuit from working properly. That's how it comes up with such descriptive and helpful diagnostic fault codes. If I'm right, you should find 4.41 volts on terminals 85 and / or 86 with the relay out of the socket.

While much less common, those 4.41 volts could also be "floating" voltages that show up due to all the other interconnected circuitry. We can't actually do any work with those voltages, and of course they do add to the confusion, but proof would be to find the normal 12 volts and near 0 volts when the circuit is activated. Floating voltages are a bigger problem in sensor circuits. When there's a break in the signal wire, you'll still find the correct signal voltage right at the sensor, but not at the computer. The voltage at the computer will "float" to some random value from the other interconnected internal circuitry. If that random voltage falls within the acceptable range for that sensor, the computer will accept it and try to run the engine or circuit on that, but it won't run right. They add the pull-up resistor to prevent that. Once the defect occurs, the pull-up resistor takes over and places, in the case of sensors, five volts on the signal terminal inside the computer. The acceptable range is from 0.5 to 4.5 volts. Five volts is outside that range, so the defect gets detected. This is where you have a fault code describing what's wrong with the signal voltage, you verify that by observing the signal voltage on a scanner, but you think you're going to double-verify that with a measurement right at the sensor and you find the correct, or different voltage there. The cause is a simple broken wire, but this has led to a real lot of confusion even among very experienced mechanics.

Friday, June 3rd, 2022 AT 2:07 PM