Okay, got it.

What was the compression numbers?

What was the fuel pressure number?

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

If it sputtered, yes, it may have some spark. The ECM does control the operation of the injectors based on the input from the crankshaft position sensor. Once the ECM see a RPM reading, it will command the injectors to fire off.

https://www.2carpros.com/articles/how-a-crank-shaft-angle-sensor-works

When you crank the engine, does the tach move up a little showing RPM?

https://www.2carpros.com/articles/crankshaft-angle-sensor-replacement

I do not see any indication of the ECM at this time.

Do you have a scan tool that can read live data?

Roy

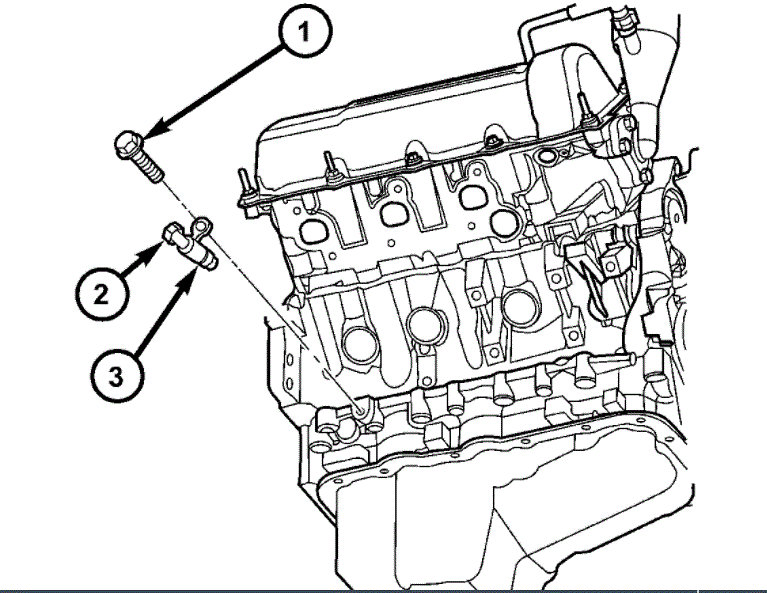

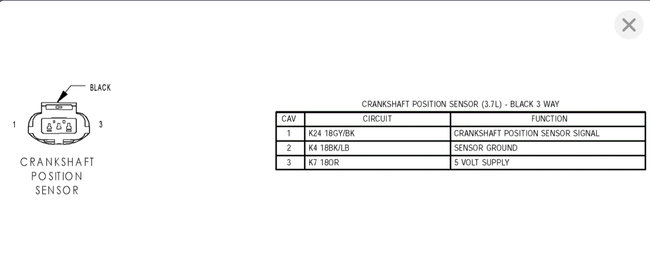

The Crankshaft Position (CKP) sensor is mounted into the right rear side of the cylinder block. It is positioned and bolted into a machined hole.

1. Raise vehicle.

2. Disconnect sensor electrical connector.

3. Remove sensor mounting bolt.

4. Carefully remove sensor from cylinder block in a rocking and twisting action.

5. Check condition of sensor O-ring.

INSTALLATION

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor O-ring.

3. Install sensor into engine block with a slight rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt, be sure sensor is completely flush to cylinder block. If sensor is not flush, damage to sensor mounting tang may result.

4. Install mounting bolt and tighten to 28 Nm (21 ft. lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

ECM

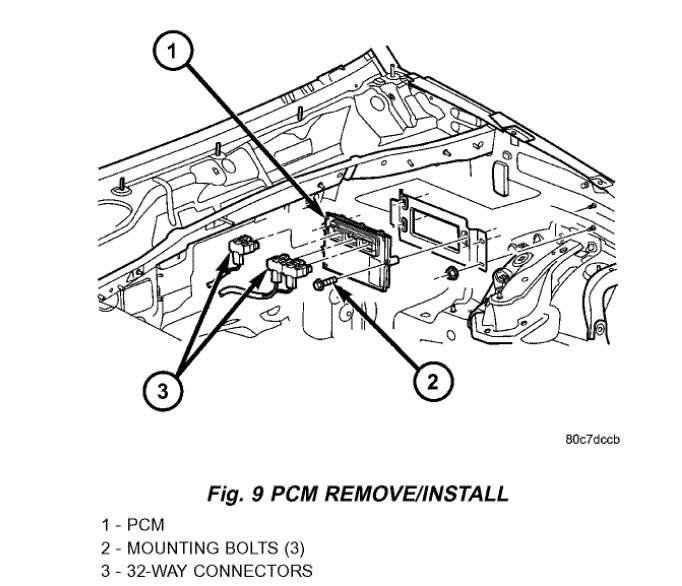

The PCM is located in the engine compartment near the battery.

To avoid possible voltage spike damage to the PCM, ignition key must be OFF and negative battery cable must be disconnected before unplugging PCM connectors.

1. Disconnect negative battery cable at battery.

2. Remove cover over electrical connectors. Cover snaps onto PCM.

3. Carefully unplug the three 32-way connectors from PCM.

4. Remove three PCM mounting bolts and remove PCM from vehicle.

INSTALLATION

Use the DRB scan tool to reprogram the new powertrain control module (PCM) with the vehicles original identification number (vin) and the vehicles original mileage. If this step is not done, a diagnostic trouble code (DTC) may be set.

1. Install PCM and 3 mounting bolts to vehicle.

2. Tighten bolts. Refer to torque specifications.

3. Check pin connectors in the PCM and the three 32-way connectors for corrosion or damage. Also, the pin heights in connectors should all be same. Repair as necessary before installing connectors.

4. Install three 32-way connectors.

5. Install cover over electrical connectors. Cover snaps onto PCM.

6. Install battery cable

7. Use the DRB scan tool to reprogram new PCM with vehicles original Identification Number (VIN) and original vehicle mileage

Images (Click to make bigger)

Monday, October 12th, 2020 AT 8:22 AM