In the days before air bags, the connection to the horn button was made by what looked like a brass nail with a spring pushing it up to make contact with a brass ring under the steering wheel. That was sufficient for a horn. A wire would twist and break within a few days so that movable contact avoided that. There could be some dirt or grease get between those contacts and cause intermittent operation but the sliding action of turning the steering wheel would always overcome that and at worst, the horn would honk a few milliseconds after you pressed the button.

Those few milliseconds are not acceptable when referring to an air bag system. The timing of when it pops is critical to its performance and you can't rely on a sliding contact so the electrical connection has to be hard-wired. That's where the ribbon cable comes in. They do not normally break from repeated flexing. They're what's used in laptop screens and anything else that opens and closes a lot.

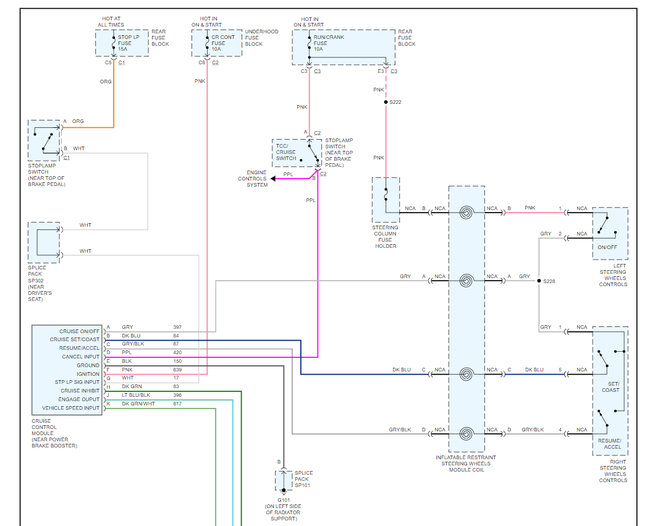

The air bag computer constantly monitors the integrity of the electrical connection to the air bag in the steering wheel. With the ignition switch on, the slightest momentary break in the circuit would set a diagnostic fault code and turn the system off. That won't happen when a ribbon cable is used. It's about four feet long and coiled inside the housing so it expands and contracts smoothly as you turn the steering wheel. As long as there are two wires in it for the air bag, it's no big deal to add two more wires for the horn and two more for all of the cruise control switches.

A sure-fire way to break a clock spring is to turn the steering wheel when the shaft is disconnected, as in when replacing a rack and pinion assembly or doing some other similar repair. If your steering wheel will turn four revolutions from full-left to full-right, the clock spring will be built to rotate about five revolutions to give it a little safety margin. It's important that the steering system be centered when a new clock spring is installed, as they always come locked in the centered position. If the steering system is one revolution to the side when you install a new clock spring, it will already be one turn off-center when you bring the steering back to center to drive straight ahead, then, when you have to make a turn all the way left or right, the clock spring will reach the end of its travel and be tugged off the rivets at the end where it makes the electrical connection, or it will expand too much and flip over on itself. After doing that a few times it will crack at the end of the cable. Even when it's installed correctly, it's only a matter of time before that ribbon cable will break.

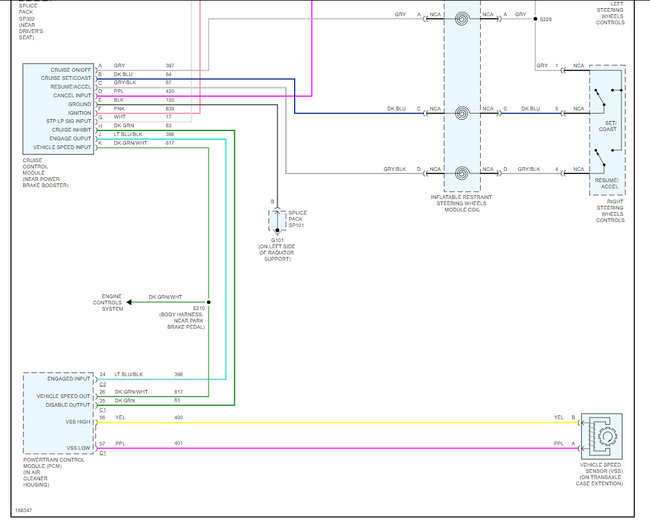

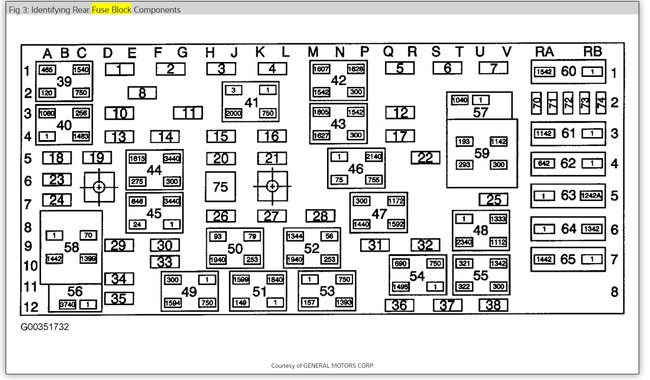

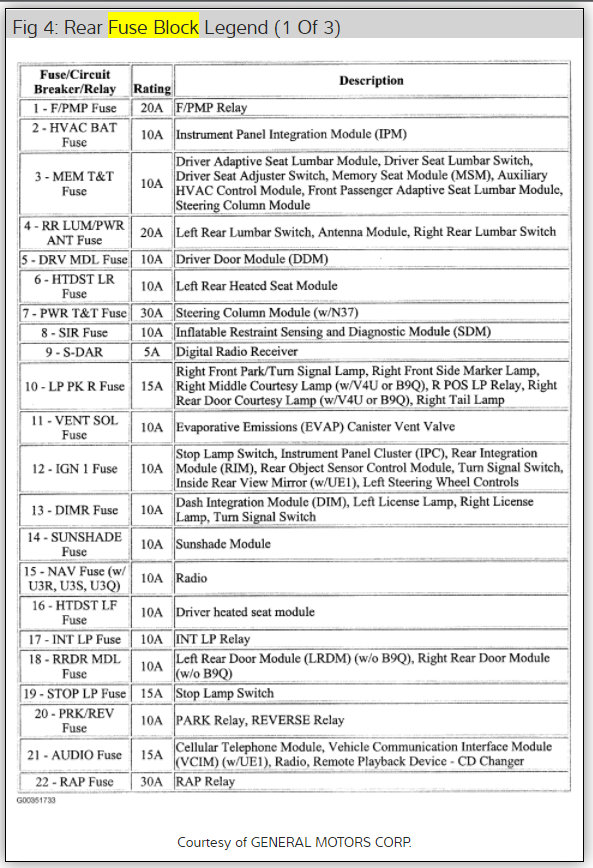

There are many other causes of a dead cruise control. There's "inputs" to the computer that you control with switches, and there's "outputs" the computer controls to make the system work. When an output circuit has a problem, the inputs will still work and the "cruise" light on the dash will turn on when it should. When the light doesn't turn on, you know it's most likely an input problem. The exception would be when the computer monitors the output circuits, detects a problem, and won't let you turn the system on. The typical response is different though. In a case like that, the light usually turns on for a few seconds, then turns back off on its own.

Other things to consider include the brake light switch. Most systems have two or three switches built into one assembly. The part for the brake lights turns on when you press the brake pedal to turn the lights on. The part for the cruise control is normally on and turns off when you press the pedal. That way a bad connection, (or switch slightly out-of-adjustment) will make the system not work or not even turn on. If that part of the switch worked like the part for the brake lights, and it had a bad connection, the cruise would not kick out when you tapped the brake pedal. That would be a safety concern.

You might be able to borrow a scanner from an auto parts store that rents or borrows tools. The factory scanner for GM products was the Tech 2. Many independent shops have them too but they are required to keep on buying new versions every few years and they're very expensive so many shops buy aftermarket brands that work on more car brands and cost less to update every year. Aftermarket scanners always do only about 80 percent of what the factory stuff does but they do it on more brands of cars. For '96 and newer cars, many shops bought the Chrysler DRB3 because with an extra, small plug-in card it will work on any car sold in the U.S, but just for emissions-related stuff. It may work for the cruise control because that's part of the Engine Computer which is primarily concerned with emissions.

You may have to visit a shop and ask if they have a scanner that will work on your car and display the switch status for your cruise control. The Chrysler scanner will also show the "reason for last cutout". If you drive into a shop's parking lot and stop the engine, you can expect the "reason" to be the ignition switch was turned off. If you left the engine running, the reason would be you pressed the brake pedal before you shifted into "park". Even if you coasted to a stop and left the engine running, the reason would be vehicle speed was below the minimum threshold for the system to engage. You get the idea. Those are all proper conditions for the cruise to not work. This feature becomes useful when the cruise kicks out intermittently such as when driving on bumpy roads. If it kicks out, and the reason listed is "on / off switch turned off", you would look at the clock spring and wiring in the steering column for an intermittent connection. If the reason was "vehicle speed too low", you might suspect the speed sensor. If the reason listed was "brake pedal applied", you'd suspect the brake light switch was out-of-adjustment. This information will at least narrow down which circuit to look at to find the cause of the problem.

When you have a hard defect such as yours, the scanner will show the switches and whether they're on or off. Some switches are supposed to be off for the cruise to work, so the Chrysler scanner and I suspect many others avoid confusion by displaying them as "pressed" or "released" instead of on or off. If you see the on / off switch displayed as "off" even though you're pressing the button, you can suspect the clock spring. All the other cruise control buttons use the same two wires in the ribbon cable so if the "set" or "resume" functions work, the clock spring is okay and you would suspect the individual buttons in the steering wheel. Those individual switches do go bad on occasion but not nearly as often as the clock spring.

You can also check for stored diagnostic fault codes with the scanner. Most cruise control servos have three solenoids and each one is monitored for continuity. One opens the port for engine vacuum to enter and pull on the rubber diaphragm to increase speed. One vents that vacuum to reduce speed. The dump solenoid disengages the servo instantly when the brake pedal is tapped. If an electrical problem is detected with any of those circuits, the computer knows it can't control vehicle speed properly so it won't turn the system on.

Most factory scanners also have a series of "actuator" tests that let you operate injectors, ignition coils, relays, and warning lights to see if they work. They don't work for the cruise control while the engine is running, but with the engine off and ignition switch on, you can often operate the solenoids in the cruise control servo and listen for the clicking sound when they activate. If all of them operate and there's no stored diagnostic fault codes, the problem is usually in the switches or clock spring. If all of the inputs are working and the dash light turns on, the last suspect is a cracked or dry-rotted vacuum hose going to the servo, or the throttle cable is broken or disconnected.

When it comes to replacing the clock spring, the air bag has to be removed first from the steering wheel. I never did one on a Cadillac, but if it's like most cars, there is a nut to remove, then you need a steering wheel puller to remove the steering wheel. By this time you will have unplugged the air bag and cruise control and horn switches. Those wires come out of the clock spring housing. The housing is usually snapped in place with plastic fingers. The easiest way to see how they come off is to have the new one in hand to look at. I tried finding a picture of the part but didn't have any luck.

The wire for the air bag connects to the clock spring with a bright yellow connector. On some versions it is plugged into the backside of the clock spring housing. On other models it is a long wire that has to be pulled down the steering column and connects under the dash. I'm more familiar with the Chrysler products. Some of their older ones are like that. The connectors fit through a tube easier than you would expect, but I like to attach a pull-wire to the old connector, then when you pull it out, the pull-wire will be there to pull the new connector down.

For liability the service manuals always tell you to disconnect the battery before removing the air bag from the steering wheel, then wait two minutes for the storage capacitors in the computer to discharge. Once the air bag or any bright yellow connector in the system is disconnected, a shorting bar engages to connect both terminals so the air bag won't pop from static electricity. I've disconnected dozens of air bags without disconnecting customers' car batteries, but I understand how hard it is to accidentally deploy an air bag, and I know the precautions to follow. For a do-it-yourselfer, I recommend following the service manual procedures just to be safe.

Monday, October 26th, 2020 AT 12:25 PM

(Merged)