Fuel injection systems are nothing new and have been around since the 1950's first being developed for aircraft which had problems using carburetors in flight maneuvers. There are two kinds of injection systems both deliver gasoline and diesel fuels, mechanical and electronic, both use injectors and fuel pumps. Mechanical fuel injection is used on older engines and has been replaced by the newer electronic systems which are more easily controlled. Today's fuel injection systems are highly regulated and monitored to achieve the best performance and efficiency.

Fuel Injection Systems

- PFI (port fuel injection)

- TBI (throttle body injection)

- DI (direct injection)

- SFI (sequential fuel injection)

- MFI (mechanical fuel injection)

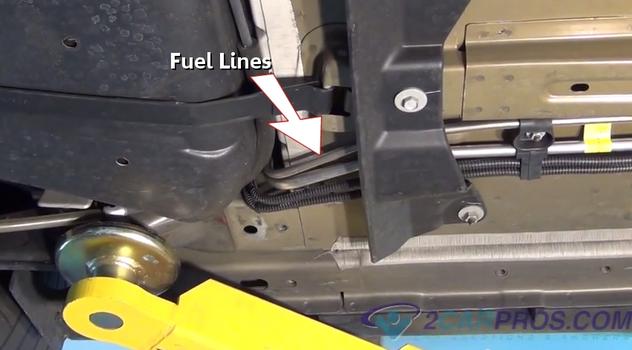

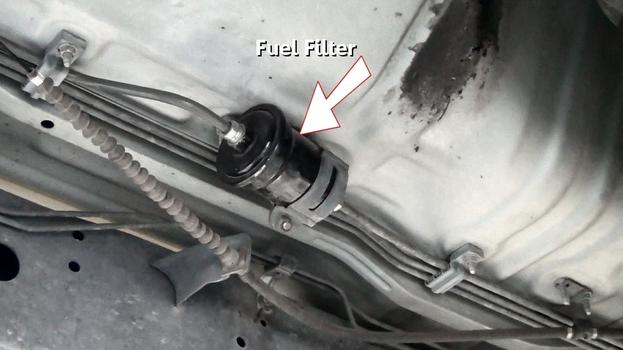

The fuel injection delivery system starts in the gas tank where the fuel is stored. A pump inside the tank delivers the fuel to the injection rail or a secondary pump depending on the type of system. A PCM is used to control the system using various sensors such as oxygen, MAP (manifold absolute pressure) and MAF (mass air flow). A fuel filter is used to remove dirt and other contaminates which can hinder the operation and efficiency of the system.

Let's see!

Here is a fuel tank removed from the car showing the

fuel pump inside which is controlled

by a fuel pump relay. At the inlet of the fuel pump there is a primary filter.

From the pump the fuel is pressurized between 14 PSI and 62 PSI as it travels

through the fuel line.

A secondary filter can be

used to further clean the fuel. Some cars and most trucks have this filter (locations

will very).

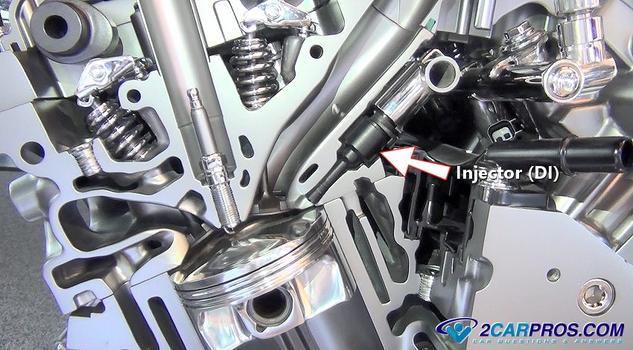

Direction injection fuel systems use a secondary mechanical pump to boost the

pressure between 900 and 1200 PSI. This pump is driven from the engine camshaft

and supplies high pressure fuel through steel lines to the injectors. This additional

pressure is needed to push/spray fuel into the

combustion chamber during the compression

stroke.

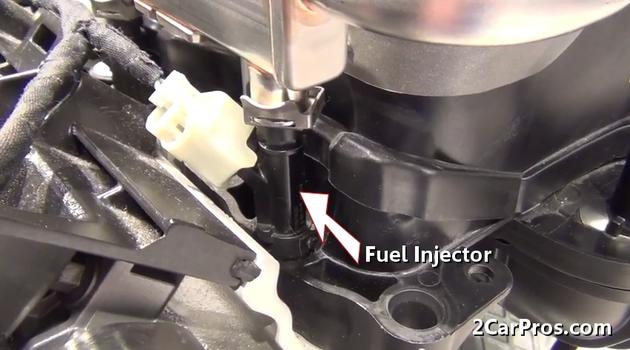

A direct injection fuel injector is mounted to the cylinder head opposed to a

traditional system where the fuel injector is mounted to the intake manifold.

The fuel injector nozzle is located inside the combustions chamber on DI systems.

This is an example of what the fuel spray pattern looks like when in operation.

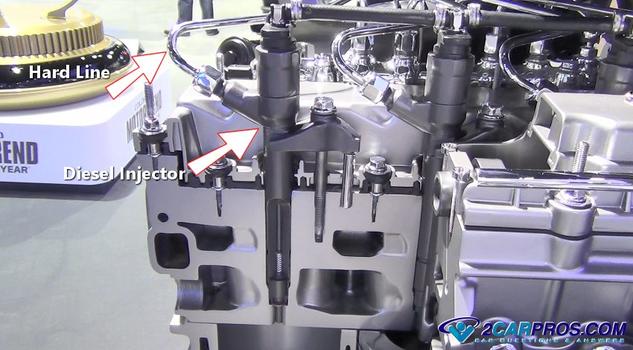

Diesel engine have always been direct injection applications. Newer versions

of diesel fuel direct injection include a high pressure oil pump to operate the

injectors, these injectors are larger in mass than gasoline injectors.

Fuel rails are used to distribute the fuel evenly to each injector in the system

and are made of metal which contain O rings to seal the injector to the rail and

cylinder head.

Traditional fuel injectors

are mounted in the intake manifold or in the throttle body on TBI systems which

do not use a secondary pump. Sequential injection delivers fuel to individual cylinder

just as the intake valve opens opposed to lesser system that can deliver the fuel

all at once or to one side of the engine or the other.

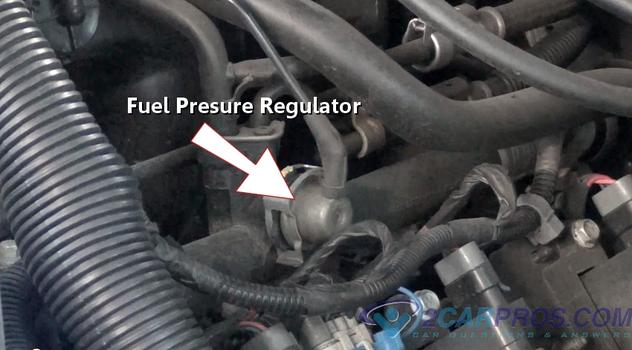

Older systems include a fuel pressure regulator which is located somewhere on

the fuel rail and is controlled by engine vacuum via a small vacuum hose connected

to the intake manifold.

Questions?

Our certified technicians are ready to answer fuel injection questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.