Introduction

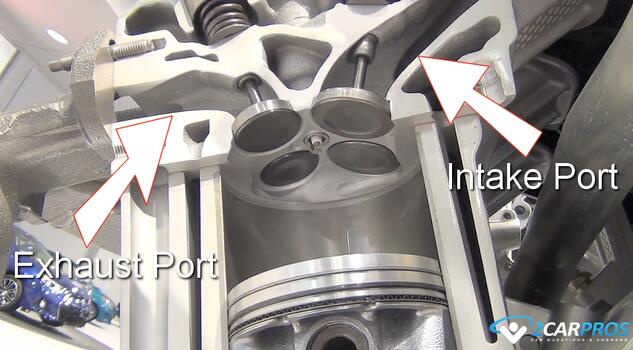

A cylinder head performs many tasks such as holding and controlling the combustion process while allowing intake and exhaust gases to enter and exit the engine. Featured in the image above is a cross section of a cylinder head that incorporates intake and exhaust ports with valves. It houses essential components such as camshafts, spark plugs, and fuel injectors. A cylinder head is fastened to the engine block using head bolts and sealed using a head gasket. This guide provides a comprehensive breakdown of how a cylinder head works, its key components, and the processes involved.

Key Components of a Cylinder Head

- Combustion Chamber - The recessed area where the air-fuel mixture ignites.

- Intake and Exhaust Valves - Control the flow of air and fuel into and out of the combustion chamber.

- Camshaft - (some models), Operates the valves via lifters, and rocker arms.

- Valve Springs and Retainers - Keeps the valves closed when not actuated by the camshaft.

- Fuel Injectors - Deliver fuel directly into the combustion chamber (direct injection) or intake ports.

- Spark Plugs - Ignite the air-fuel mixture in gasoline engines.

- Cooling Passages - Allow coolant to circulate, preventing overheating.

- Oil Galleries - Deliver lubrication to moving components.

Types of Cylinder Head Designs

- Overhead Valve (OHV) - Pushrod engines where the camshaft is in the engine block.

- Single Overhead Camshaft (SOHC) - One camshaft per bank, controlling both intake and exhaust valves.

- Double Overhead Camshaft (DOHC) - Two camshafts per bank, allowing more precise valve control and higher RPM capability.

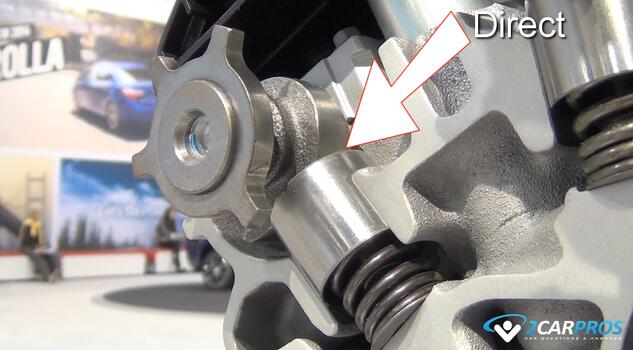

- Direct Valve Train - No rocker arm or push rod design.

Cylinder Head Functionality

1. Combustion Chamber

The combustion chamber is where the magic happens and is the "end game" of the cylinder heads purpose. This is where the fuel air mixture is combusted to converter the kinetic energy into linear motion via the engine piston and crankshaft.

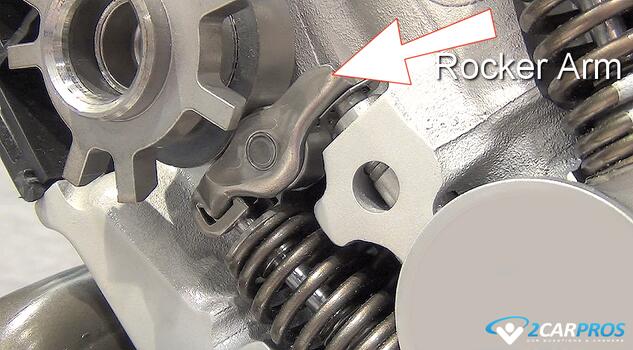

2. Cylinder Head Rocker Arm

A rocker arm is used to open and close the intake and exhaust valves, in most overhead camshaft, and in all in-block camshaft configurations. You can see the valve lifter and valve spring as well, (positioned at opposite sides) with the camshaft above the rocker.

2. Valve Lifter

Utilizing engine oil pressure, a valve train lifter is used to help adjust the gap "lash" between the camshaft and the intake and exhaust valves, which can be located inside the cylinder head or engine block depending on design. The lifter can also adjust to accommodate the valves expansion as the engine heats up. This operation helps the valve stay sealed to the valve seat located in the cylinder head.

4. Direct Valve Configuration

This is what it looks like when the valve is placed directly under the camshaft with no valve train. The valves are placed directly under the camshaft to minimize moving parts and achieve higher engine RPM's.

5. Intake and Exhaust Valves/Ports

Intake and exhaust valves and ports are designed into the cylinder head to help allow the intake charge enter the combustion chamber, and post combustion, for the exhaust gasses to exit the engine.

6 Spark Plug

An ignition system spark plug is used to ignite the intake charge via the ignition coil and computer system program. The plug is designed into the cylinder head and more specifically the combustion chamber. In the image (cutaway) below, a rare sight, the spark plug tip as seen from inside the engine ready to begin the combustion process.

7. Cylinder Head Cooling

The cylinder head, along with the rest of the engine components need to stay cool while in operation. Engine coolant is used to help keep the cylinder head cool as coolant passes into the cylinder head through the engine block and is sealed by the head gasket

8. Cylinder Head Accessories

A cylinder head also supports a host of accessories such as:

- Fuel injectors

- Temperature sensors

- Camshaft position sensors

- Camshaft actuators

- Ignition coils

A valve cover is bolted to the cylinder head and is used to control oil leaks and internal crankcase pressures. This cover is sealed to the cylinder head using a valve cover gasket, a crankcase vent is also located on or near the cylinder head.

Conclusion

The cylinder head is a metal component, typically made of aluminum or cast iron, that sits atop the engine block. It seals the top of the combustion chamber and provides passages for fuel and air intake, exhaust gas exit, and coolant circulation.

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.