We are a team of ASE certified mechanics that have created this guide to help you save money while doing the job yourself, or at least see what you are paying for when having the job done at a shop. An engine is designed to operate smoothly, as with any engine a slight vibration is normal, but a notable vibration is telling you something is wrong, which can be a minor issue like a vacuum leak or a more serious problem such as low compression or balance shaft issues.

Isolating the Vibration

Vibrations can be caused by internal engine factors or external problems, first remove the serpentine belt and then start the engine to see if the vibration goes away, if so, you know the problem is external such as a serpentine belt tensioner. If the problem is still there you know the problem is internal such as a balance shaft issue. Also, the vibration could be more noticeable when the engine is under load.

Vibration (Serpentine Belt Installed)

A serpentine belt tensioner is designed to keep the belt tight during the engine

operation and to take up the slack as the belt naturally wears. This spring loaded

pivot based part can wear allowing the belt to "bounce" as it loses and gains traction

among the drive and accessory pulleys which can be seen by observing the tensioner

while the engine is running, it should be relatively smooth. If you notice a large

vibration the serpentine

belt tensioner needs to be replaced, the

serpentine belt should be replaced

as well.

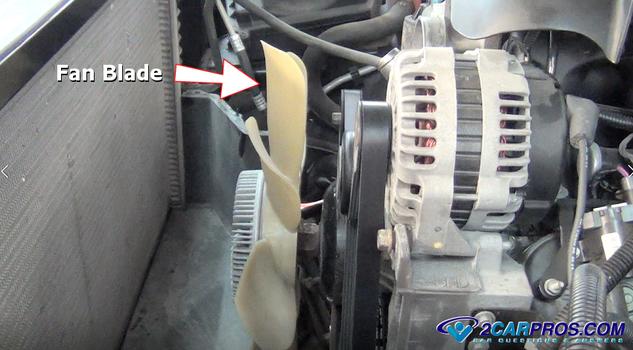

An engine cooling fan can be driven by the engine or powered electrically, both

configurations can cause a vibration. Inspect the fan's integrity to ensure the

blades are intact and there are no missing parts, this will cause the fan to rotate

out of round which produces a vibration. Also, when a

fan clutch or

fan motor wears it can fail to

hold the fan blade true, with the engine not running (key off) grasp the fan to

check for play.

When an air conditioner is overcharged it can cause an engine vibration when

the HVAC system is on due to higher than normal pressures, this causes the compressor

to overwork itself creating a vibration. This can also be caused by too much compressor

oil in the system. Check

the internal pressures of the air conditioner system and adjust and lower the

high side pressure.

With the belt removed, grasp the remainder of the accessories driven by the belt and spin by hand to check their rotating ability, this can detect a bad bearing which can cause a vibration and warrants replacement.

Vibration (Serpentine Belt Removed)

Engine mounts are a vulcanized rubber mount that the engine and transmission

rests upon to shield the car frame and body from the natural operational vibrations.

These mounts are two pieces of preformed metal held together by a piece of vulcanized

rubber and are subject to wear and stress as the engine torques when accelerating

allowing the engine and transmission to rest against the frame of the vehicle causing

a noticeable vibration. The best way to inspect an engine mount is from under the

vehicle using a flashlight to check the integrity of the mount, the failure will

be obvious as the rubber part will be blown out, torn or missing which warrants

an engine mount replacement to fix

the problem. Some mounts are oil filled which will be leaking, another indication

of failure.

A balance shaft mechanism consists of two counter weighted shafts driven by the

crankshaft, a balance shaft belt or chain is used to rotate the shafts to counteract

vibrations created by the natural characteristics of the engine's operation. The

belt or chain can break or become out of synchronization with the crankshaft either

by worn timing components, or a possible misalignment when assembled. To inspect

for this problem, remove the timing belt cover and inspect timing belt or chain

marks for proper alignment. These shafts can also be driven from an independent

balance shaft belt or chain which can be separate from the

camshaft timing belt or chain. If

the balance shafts are non-operational due to mechanical failure or wear the engine

will vibrate, here is an image of the engine balance shafts which can cause a rattling

noise when bad as well.

Engines are designed to be internally or externally balanced, this is achieved

by counter balances in the harmonic balancer or the flywheel-flex plate. If one

of them has a problem or the incorrect parts have been installed the engine will

have a noticeable vibration. Below is an image that shows a harmonic balancer that

has come apart which can produce an abnormal noise.

Vibration Under Acceleration

When an engine misfire

occurs it will cause a vibration which will begin happening when the engine under

load or acceleration, all engines are symmetrical and when part of the cycle is

missing the engine becomes off balanced. This can trigger a check engine light which

can help detect the particular cylinder having the issue.

Front wheel drive vehicles are designed with an additional engine mount called

a torque mount, this mount helps control side movement of the engine while under

acceleration. When a torque or support mount fails it will start allowing the engine

to move excessively causing damage to the CV

axles while producing a vibration. To check for this problem lift the hood and

observe the engine, then have a helper start the engine and while applying the brakes

shift the transmission from reverse to drive, the engine should move slightly. If

excessive movement is noticed the torque

mount is bad and needs to be replaced.

Vibration at Idle Only

Vacuum leaks are a major source of engine idle vibrations, this is because when

an engine is at idle it depends on the intake system to hold said vacuum more than

any other time of the engine's operation, (when an engine is under load, the vacuum

is reduced). Most of the time a broken vacuum line can be easily observed. To

test for a vacuum leak

start with the engine cool and allow to idle, use carburetor cleaner and lightly

spray around the vacuum hoses (avoid exhaust manifolds) if the idle speed increases

you have located the source of the leak.

Low compression in one cylinder can cause an engine vibration at idle, this is

because an engine depends on an equal amount of compression in each cylinder to

run smoothly. If a tune up has

been done recently and you think this can be the problem a

compression test needs to

be performed.

The intake valve must seal completely for the engine to run smoothly at idle,

if an intake valve leaks it will allow exhaust gases to enter the intake manifold

and into the intake charge of the additional cylinders causing a vibration at idle.

To test this condition a leak down test must be performed, if positive results are

produced for leakage, a valve job is required.

Questions?

Our certified technicians are ready to answer engine vibration questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.