Introduction

Clunking noises in a vehicle can be unsettling and often indicate that a critical component in your car's suspension, steering, or drivetrain is damaged or worn. These sounds may occur when you drive over bumps, take turns, or accelerate. This step by step guide shows what causes the clunking, and how to repair the problem.

Tools and Supplies Needed

- Flashlight

- Socket set

- Wrench set

- Protective eyewear and clothing

- Shop towels

- Jack and jack stands

Like with any sound problem, the first step is find out where it's generated from, front, middle, rear, right or left, this is where the inspection will begin. Also, take note to when the sound is generated, such is when you put the car in gear, or when you travel over a bump. The car will need to be raised up on jack stands for this inspection, so park on level ground with the engine off and the parking brake on.

Clunk In Gear

1. If there is a clunk and kind of a light ting noise when the car is put into drive or reverse it could be the driveshaft U joints or CV axles are worn out. Use a flashlight to look for rust colored dust at the U joint itself, this is a sure sign the U has failed and needs replacement, or if there are torn CV boots and the CV axles now have water damage it will create this noise.

2. If the clunk occurs heavily at the front or middle of the car, the engine or transmission mounts can be broken allowing excessive movement from these components. In other words the engine will rise up when accelerating, and then falling back down on deceleration, the same can be said for the transmission. To inspect for this problem, use flashlight to check the engine mounts and look for separation of the rubber and metal mounts which hold the mount together. If separation or leakage is detected, the mount must be replaced.

Clunk When Braking

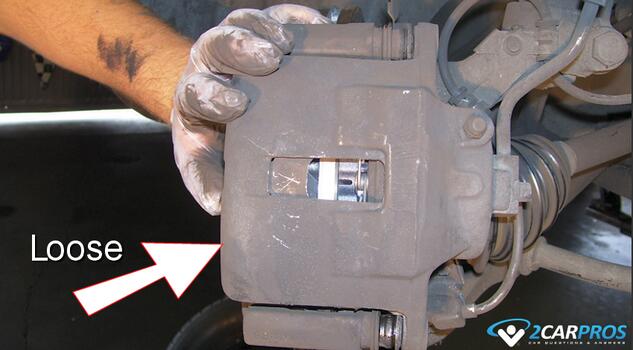

1. The brake pads and calipers are designed to slow the vehicle when applied. If the caliper is loose, or if the brake pads are not fitted properly, they will make a clunking noise when the brakes are applied. Remove the tire and gasp the brake caliper to wiggle it back and forth to check for movement, also check the brake pad fitment and ensure the anti-rattle clips are in place.

2. Worn tie rod ends can cause a clunk while braking due to the force the brakes provide while trying to stop the rotation of the tire. Use a flashlight and grab the wheel at the 3 o'clock and 9 o'clock positions and shake it side to side or have a helper move the steering wheel back and forth slightly, while you watch for slop at the inner or outer tie rod ends, replace any that have play.

Clunk While Driving Over Bumps

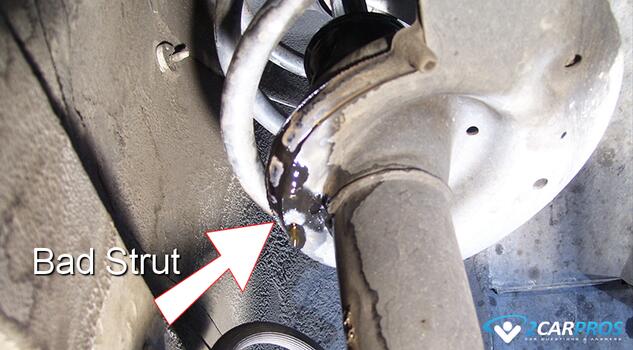

1. Struts and shocks are created with hydraulic dampening valves which fail causing a clunking noise. Use a flashlight to looks for obvious signs of leakage which indicates the strut or shock has failed, and needs replacement. In the example below the seals have let go and the shock is blown out.

2. Worn suspension parts such as a sway bar mounts and control arm bushings can cause clucking as you drive, these to are easily inspected with a flashlight, you are looking for missing or blown out bushings, this will be obvious. Please go over this guide for more information: Suspension Noises

Conclusion

Clunking noises in a vehicle can be caused by several components, including suspension parts, steering systems, drivetrain, or exhaust components. Diagnosing and repairing these noises is critical to maintaining your vehicle’s safety and performance.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel for additional car repairs.