Abnormal noises from your car's suspension are telling you there is a problem, nine times out of ten there will be a noticeable physical issue with a particular component that can be detected with a simple inspection. The following are popular failures and the repairs needed to get you back on the road safely.

What Goes Wrong?

Suspension components are subject to wear during the normal operation of the car, with EV's the problem is worse due to the added weight of the battery and torque of the electric motor. When a telltale noise is discovered try to isolate the region and if there is a particular condition that is creating the sound. Noises can be created when driving down a bumpy road or at a particular speed.

Let's Jump In!

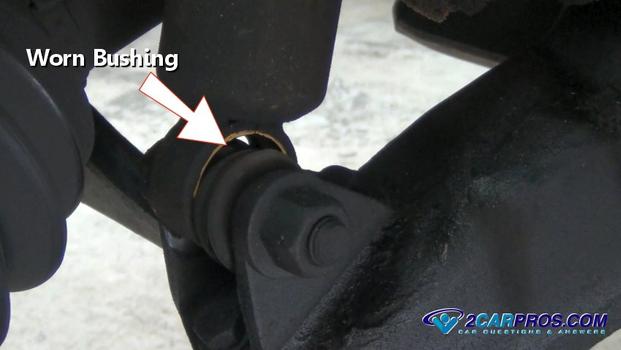

In the image below note the missing bushing at the end of this shock. This will

create banging, tapping or rattling sounds when the vehicle is driven down a bumpy

road. In this case the shock must be

replaced because the bushing is non-serviceable.

When a strut goes bad it will lose the oil from inside the unit which is detectable

on the outside of the strut body allowing the mechanism inside to run dry that can

cause bumping or pounding sounds, additionally there is a strut plate located at

the top of the shock which is made of rubber that can also fall apart causing the

same kinds of noises. The image below shows old

struts which are

being replaced with a new strut assembly.

A sway bar is designed to control side roll or lean when driving into a corner

and can be fitted to the front or rear of a vehicle. These sway bars are mounted

to the frame and connected to the suspension arms using connecting links. If a sway

bar mount or the connecting links become worn or loose it can generate a banging,

popping or rattling sound. When inspecting for this problem check the mounting bolts

and bushings, if the bushing is loose or completely gone the

sway bar link needs to be replaced.

Control arm bushings are designed to allow the suspension arms to pivot near

the frame mounts. These bushings are constructed of two metal collars, one large

and one small with rubber molded inside. Time and usage cause the rubber inside

the bushings to deteriorate allowing the suspension arm to rattle or make creaking

noises. To check for this condition use a flashlight to view the upper and lower

control arm bushings. If rubber is missing or pushed out they must be replaced,

control arm bushings are generally serviced by

replacing the complete control

arm.

An upper and lower ball joint has two jobs, first it allows the universal movement

needed when steering the vehicle, second it allows the movement to the upper and

lower control arms when going over bumps in the road. This joint is constructed

of a metal base in which the ball rides inside of. Both parts are made of metal

and require grease to work freely. These joints are under extreme pressure and can

cause suspension noises when they are worn out or need lubrication.

Questions?

Our certified technicians are ready to answer car repair questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.