Okay, I'm not sure if I'm doing this right as I'm still learning how to use the new obd2 so please bear with me here.

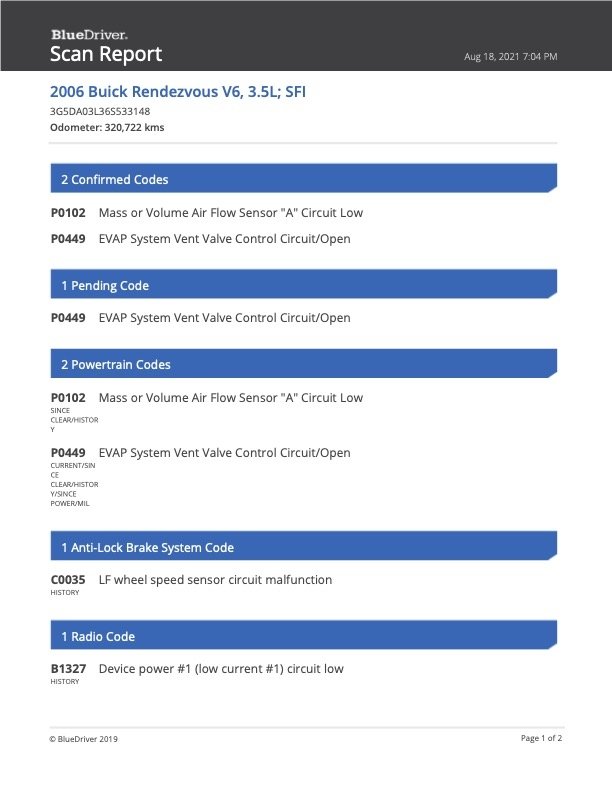

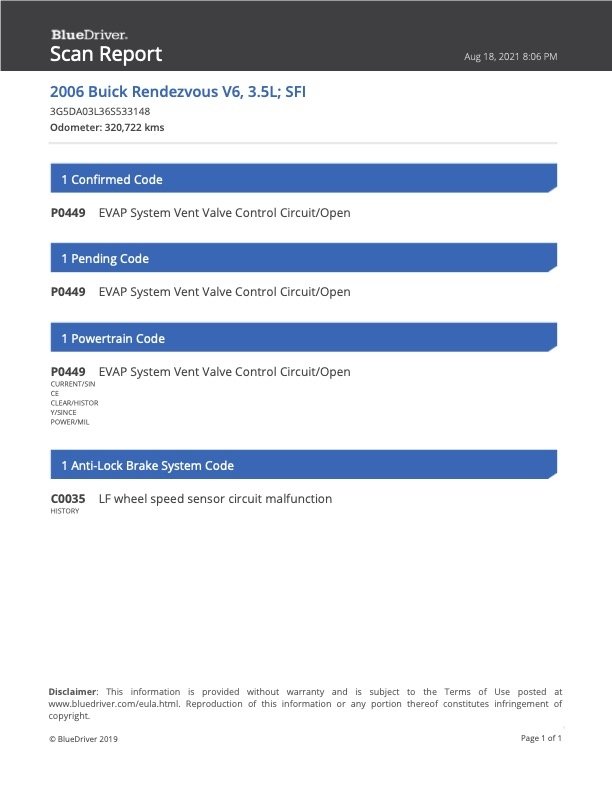

I did a full code scan. I found out my ABS is a circuit/wire behind my front left wheel. Totally cool, I can now fix that as I always wondered what it was.

Also, my P0449 says its the EVAP Canister Vent Solenoid circuit, so I might just tackle that as well this month and replace the evap canister vent valve solenoid thing. I may have to drop the tank to do it, but it could go okay if the straps come off easily.

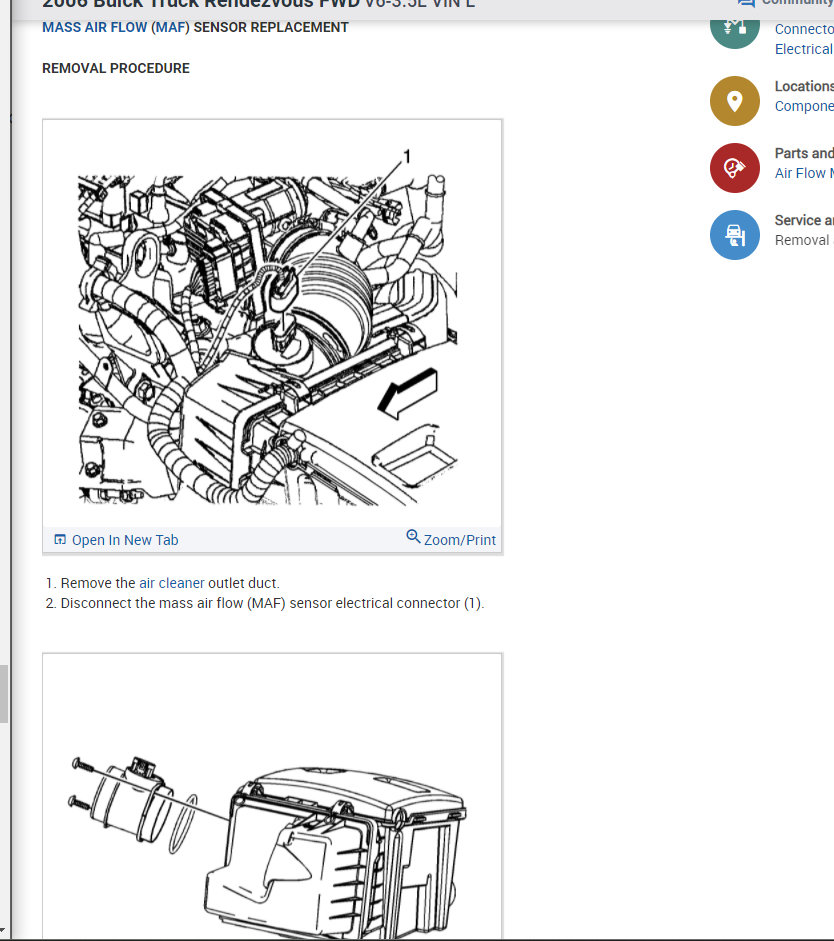

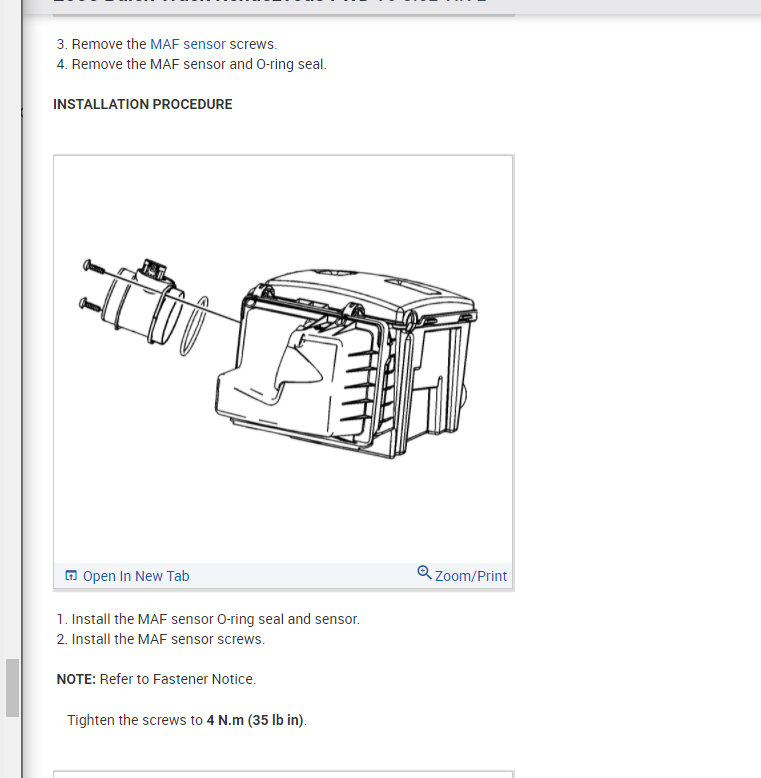

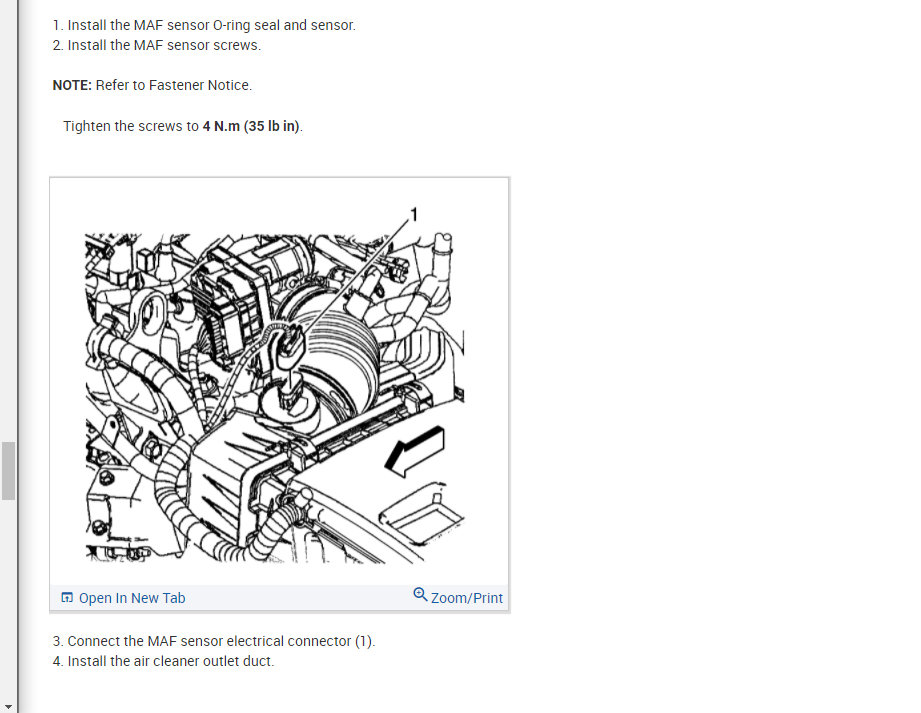

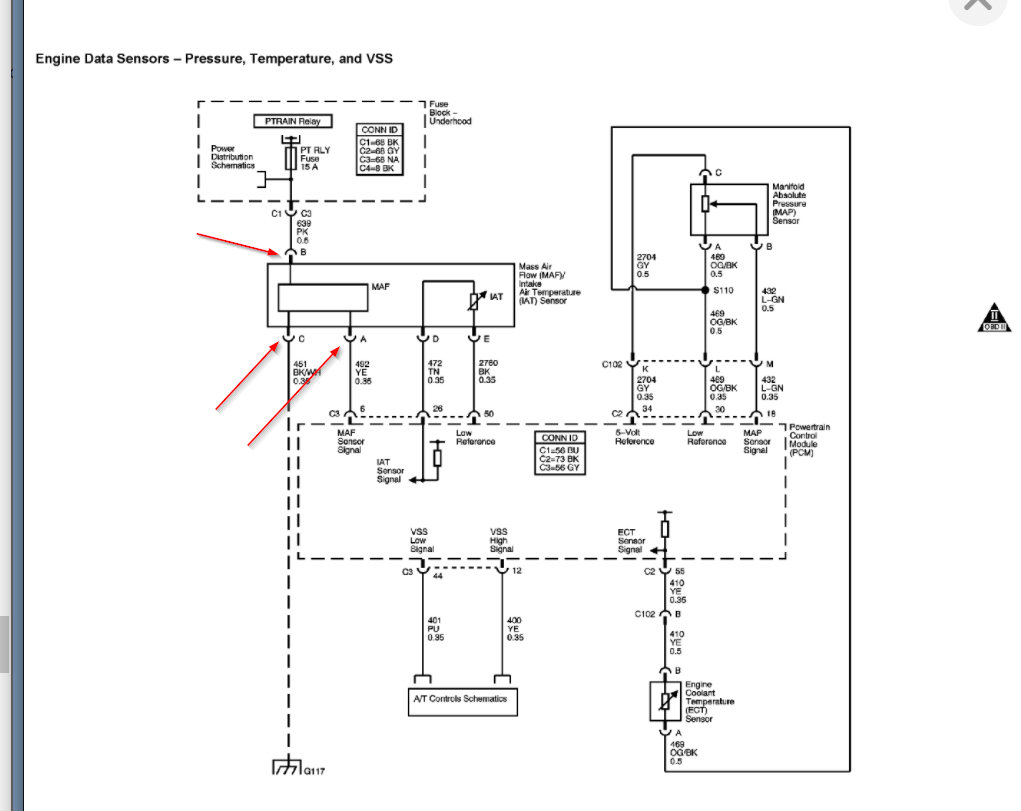

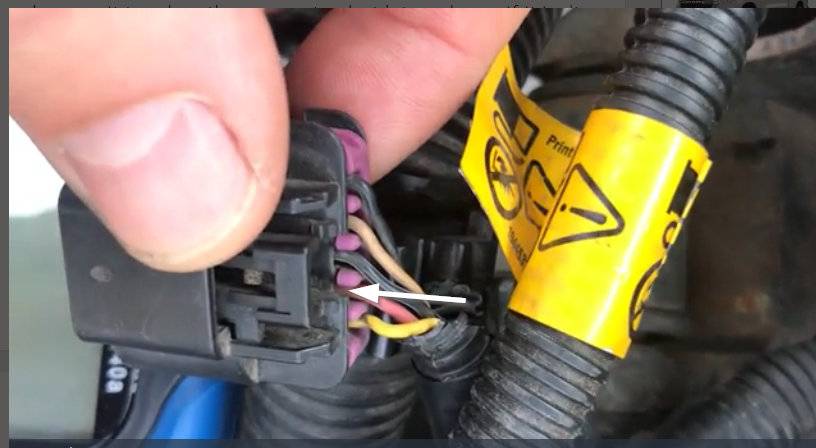

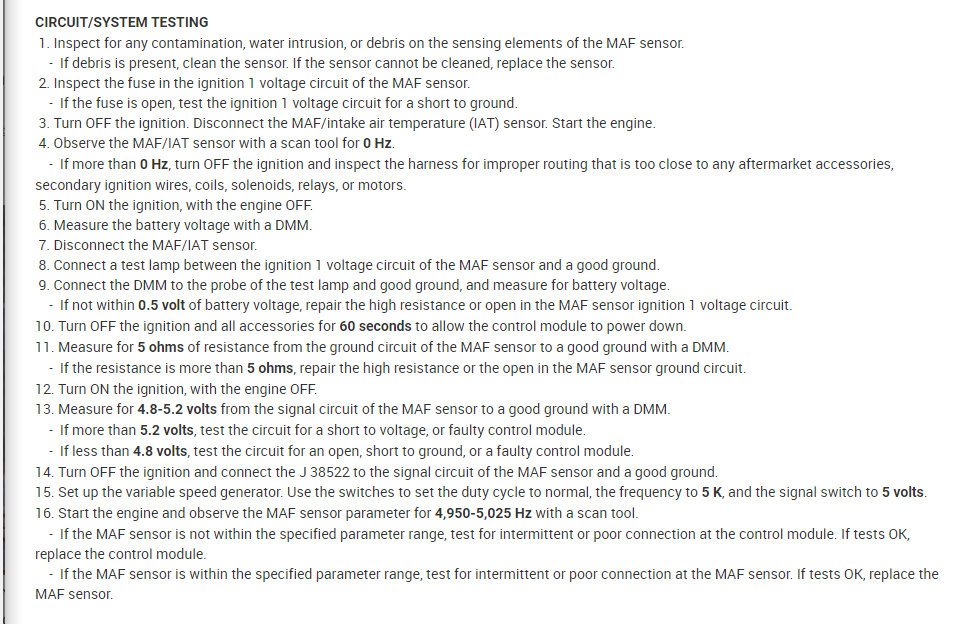

It showed a P0102 (MAF) but I'm guessing that was triggered sometime during all my testing when I unplugging the MAF etc. So I cleared all the codes and took it for a good hard drive for a while and then rescanned. The results were the same except the p0102 code never reappeared despite it surging badly, so I'm pretty sure that code was from the testing we did earlier.

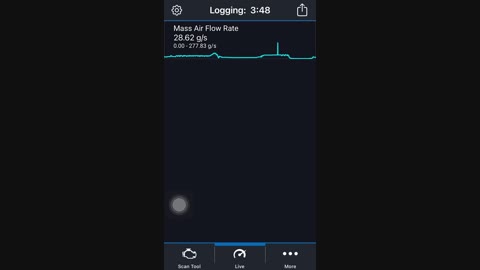

Lastly, I tried live data. It had tons of options to choose from (see attached video) so I picked what I thought you were looking for (the Mass Air Flow) and screen recorded it as I drove. The grams/second seem to climb steadily as I drove faster, then when it gasped for air it quickly dropped, and when it surged with power again it climbed. You can see the 20 grams spike approx. 20g/s during the test when it was gasping/surging. When it wasn't gasping/surging it was very steady.

Images & Videos (Click to make bigger)

Thursday, August 19th, 2021 AT 1:39 PM