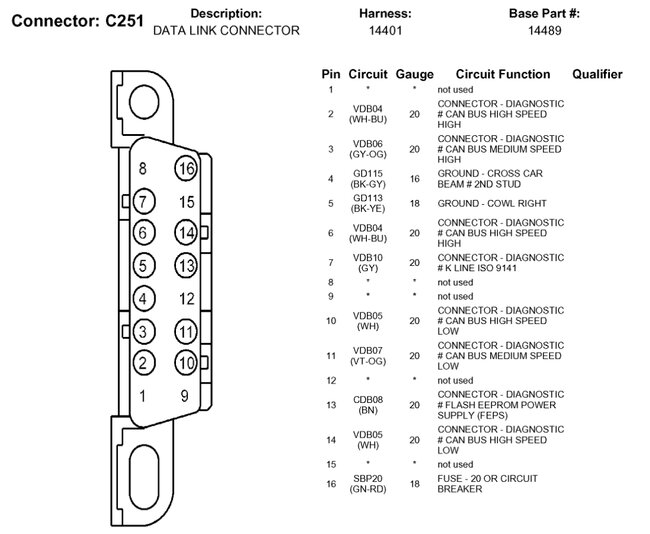

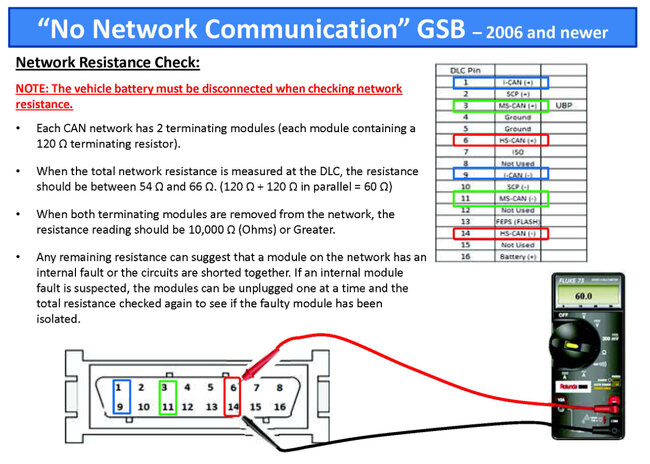

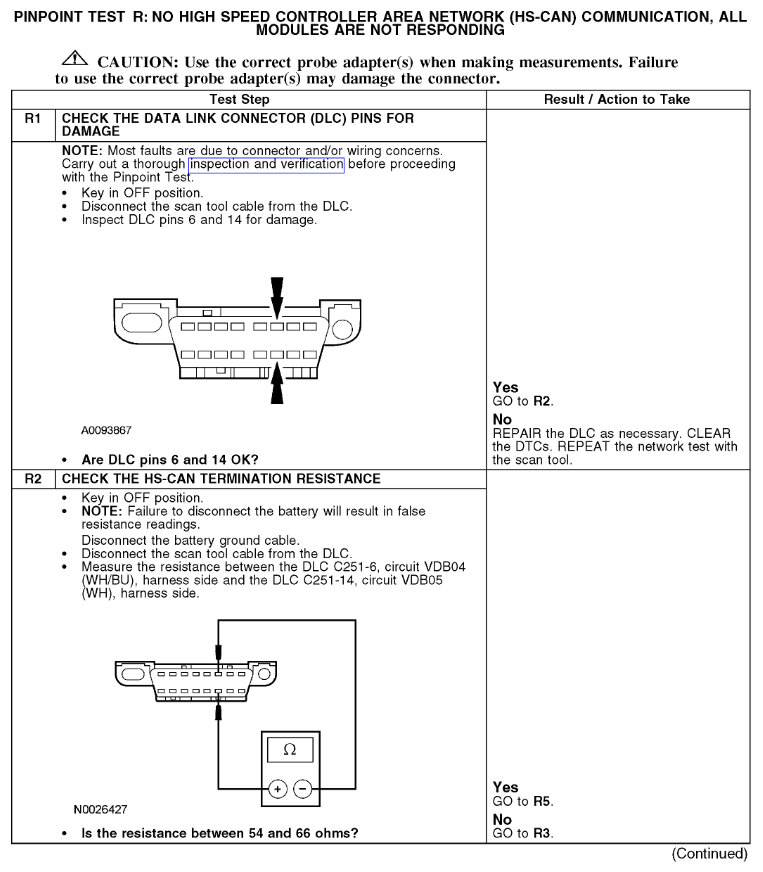

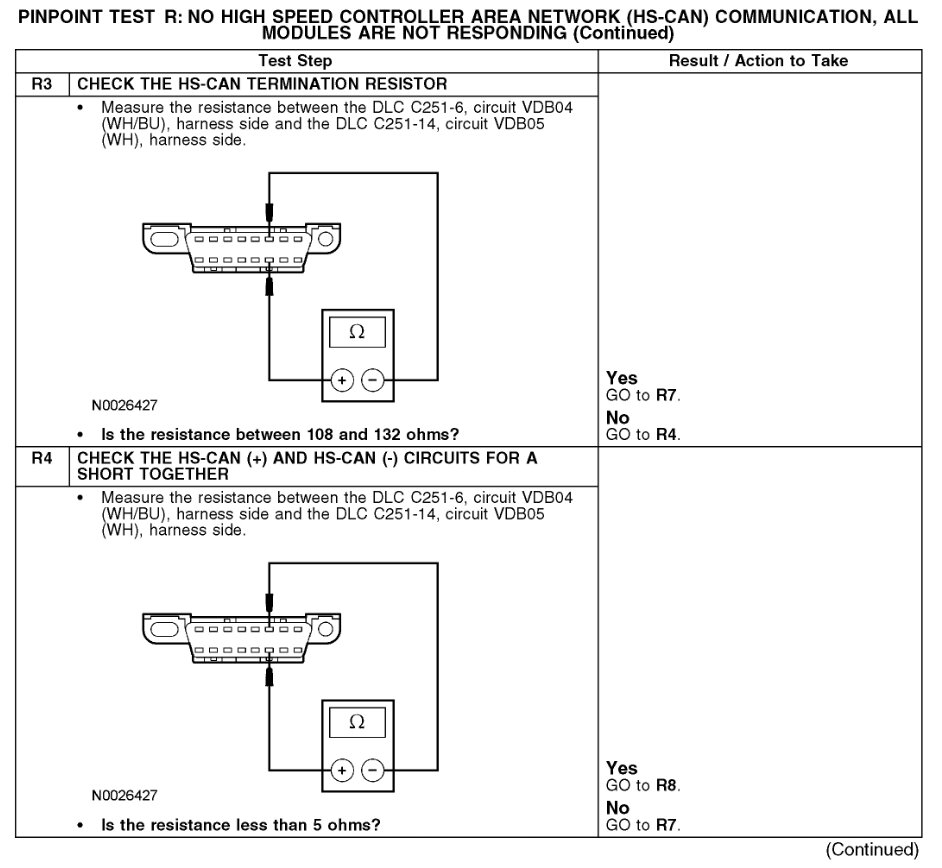

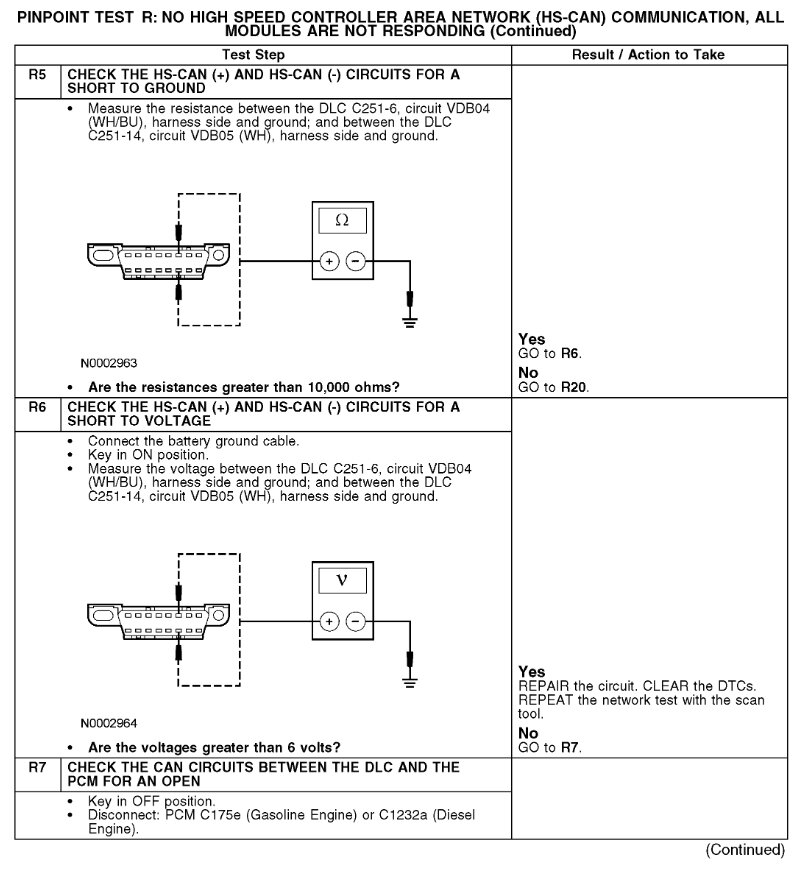

Honestly, I wish I could give you easier tests to do. I know the flow chart is a ton of steps and it can be easy to lose your place. But knowing that you are reading barely any voltage at all, I think maybe unhooking the battery negative, give it 10-15 minutes and then see what the resistance reading to ground is on pin 14 and 6. Using the battery negative cable for your ground instead of pin 4 or 5. And see what you get before you start on the flow chart. One other thing I was wondering, what were the readings on each pin 14 and then pin 6.

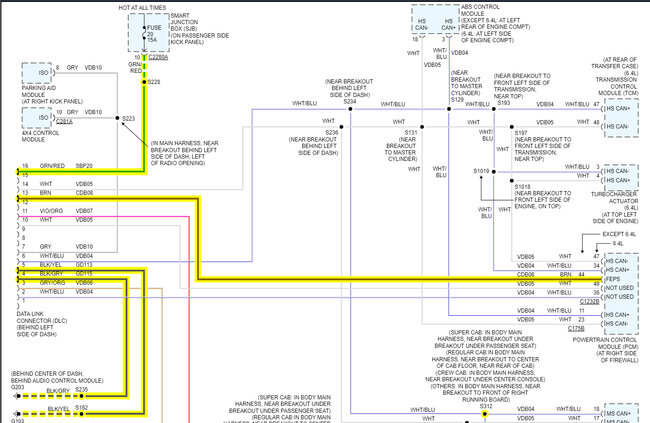

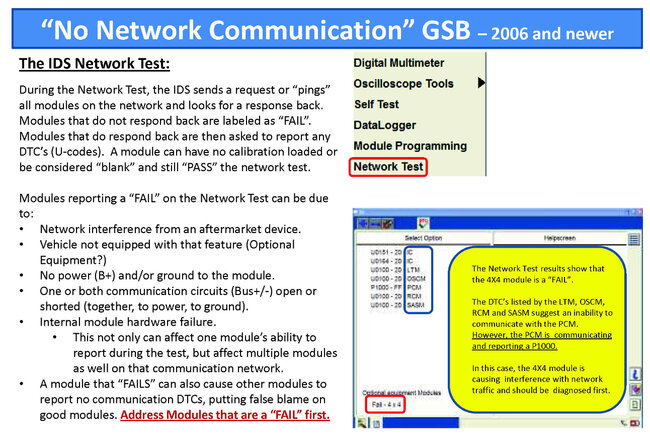

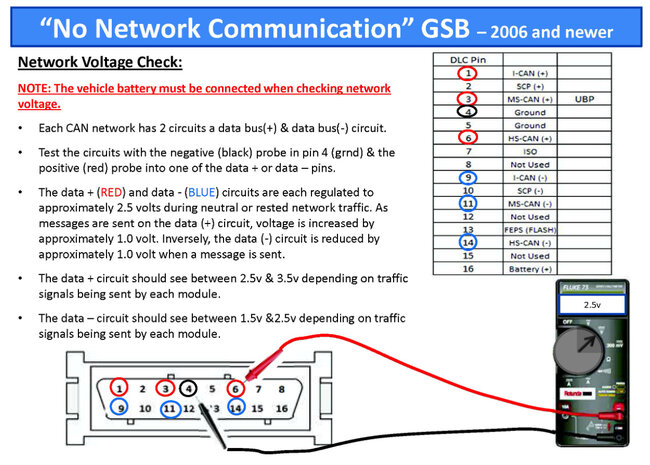

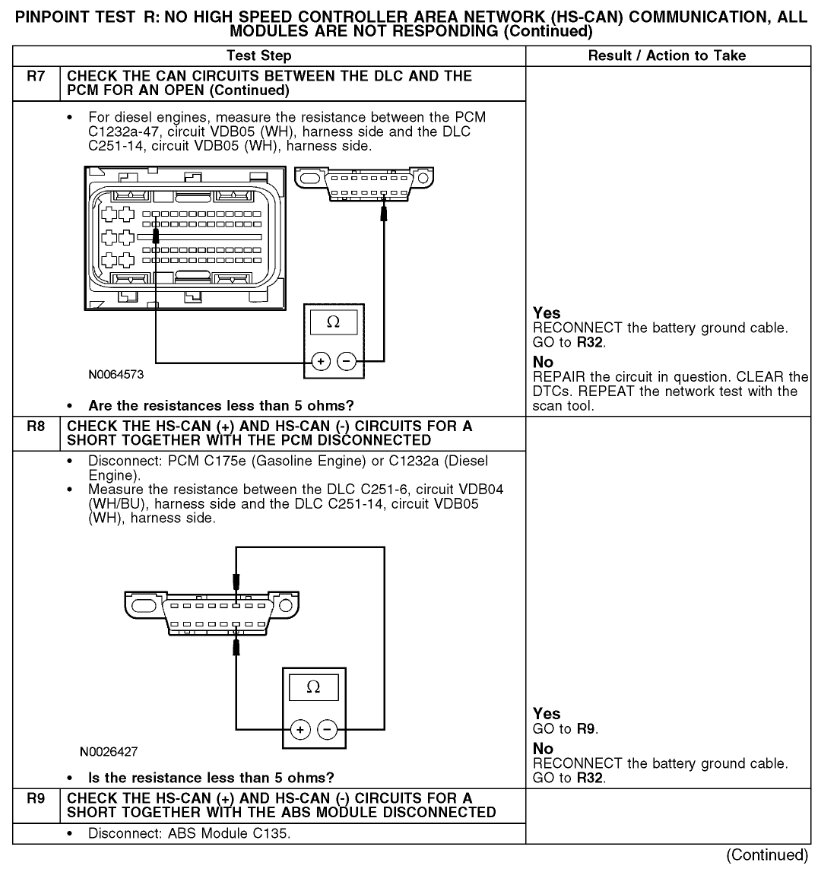

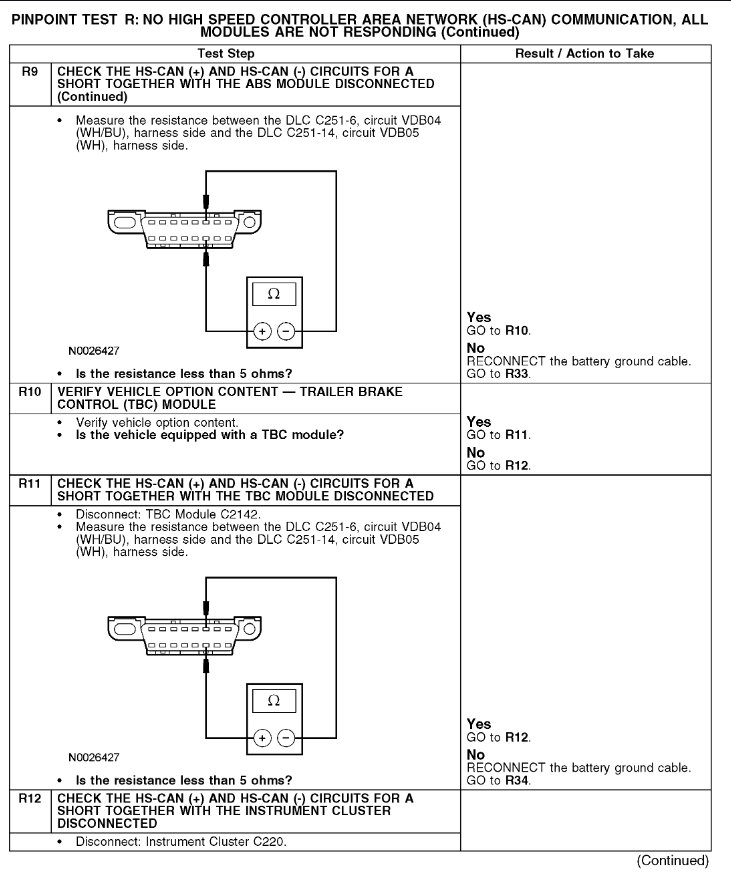

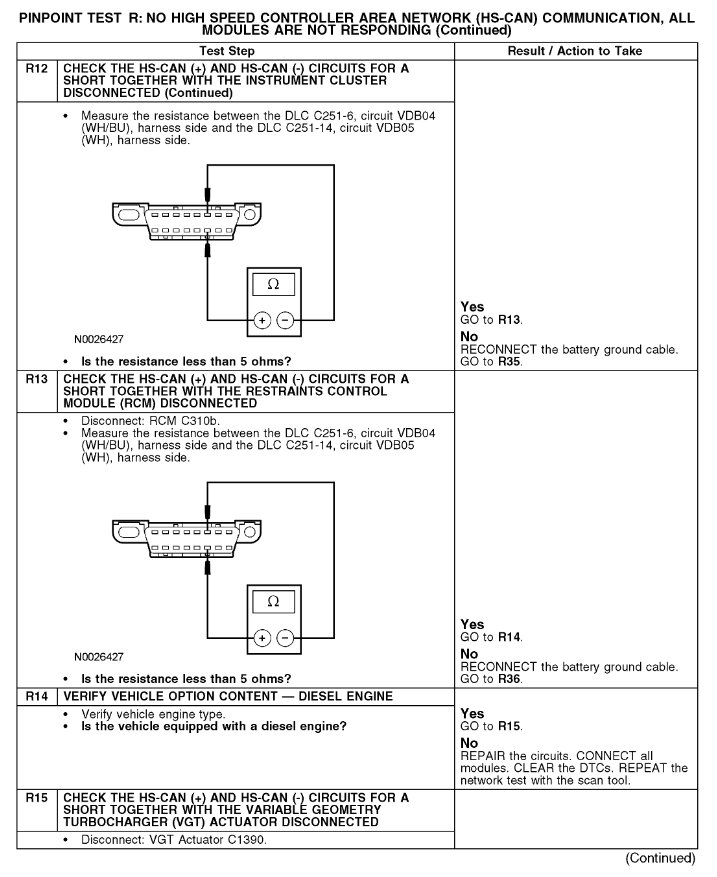

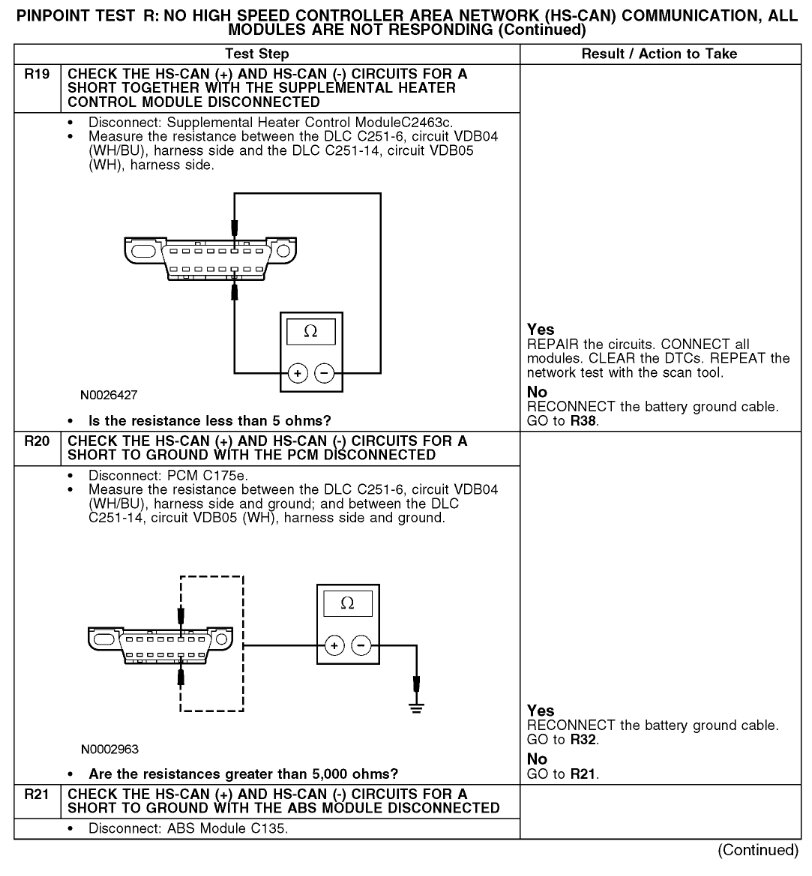

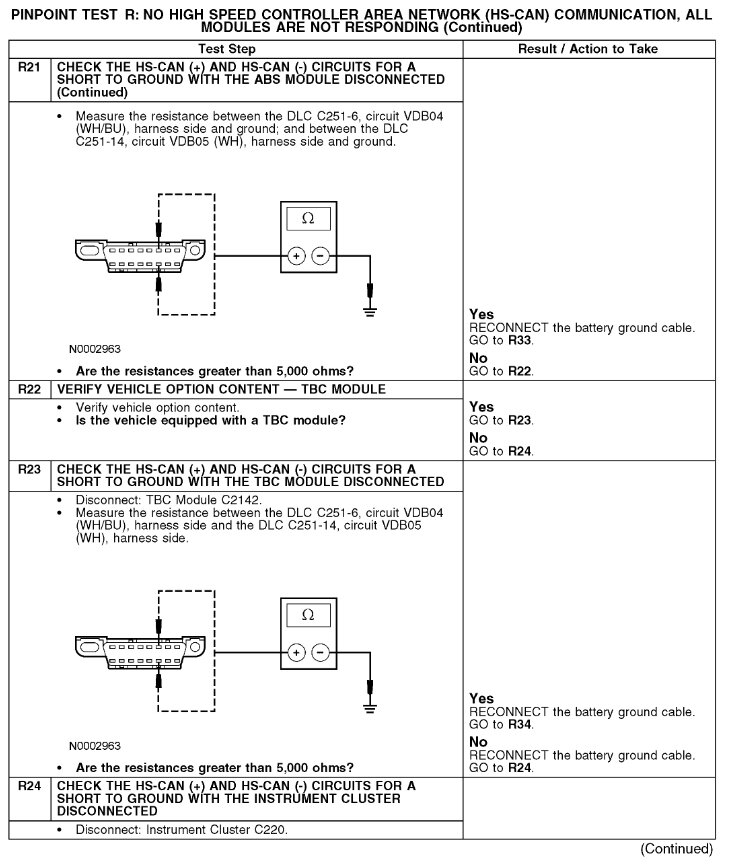

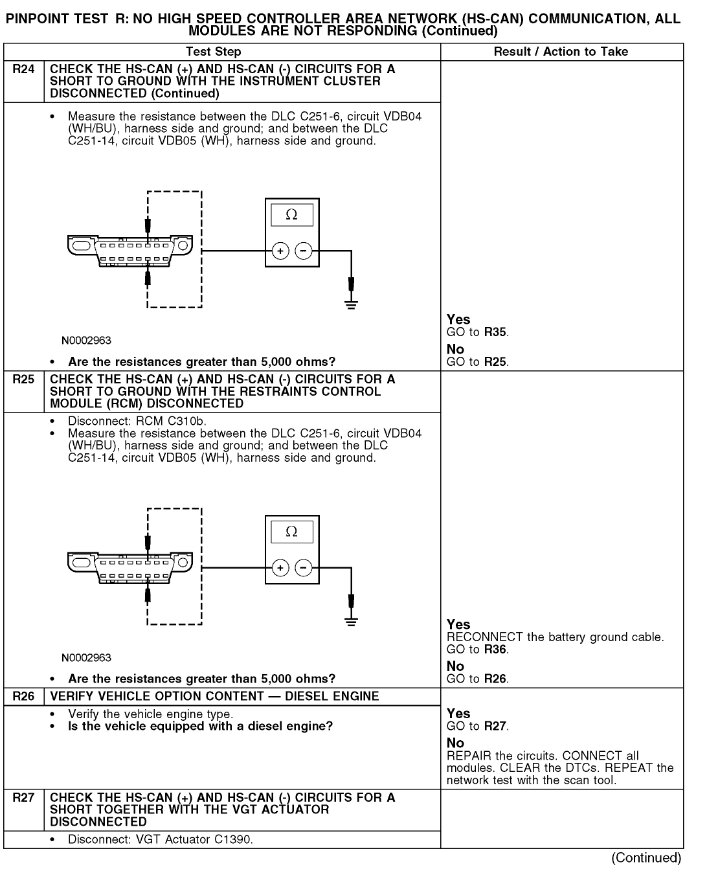

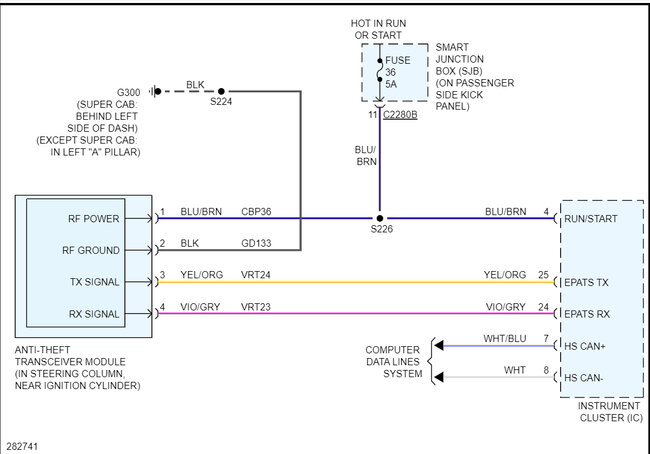

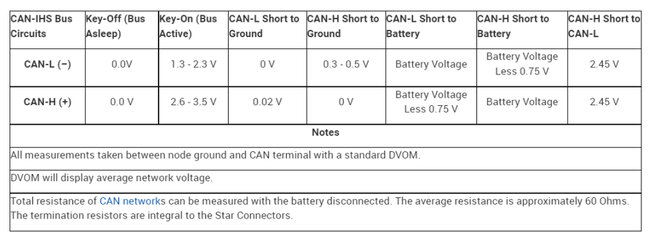

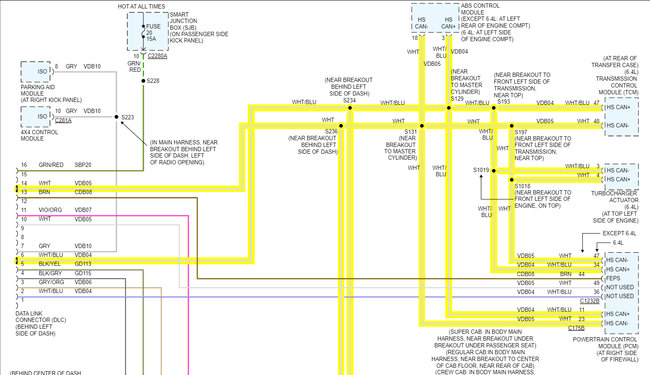

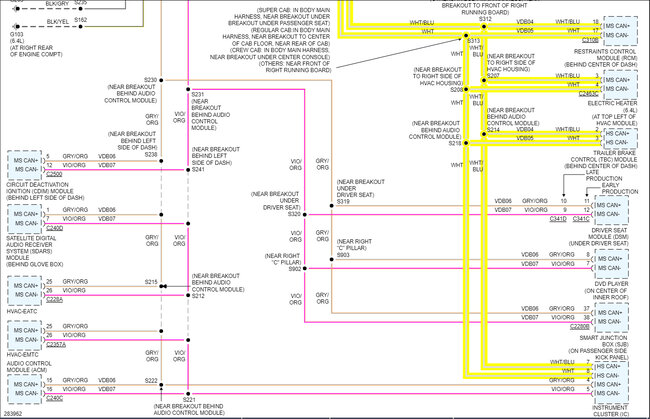

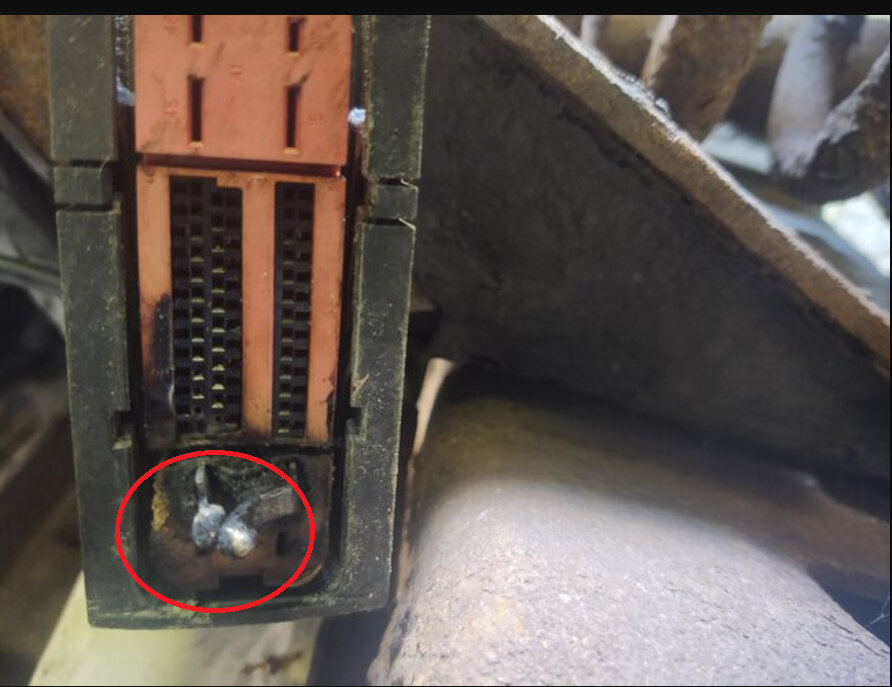

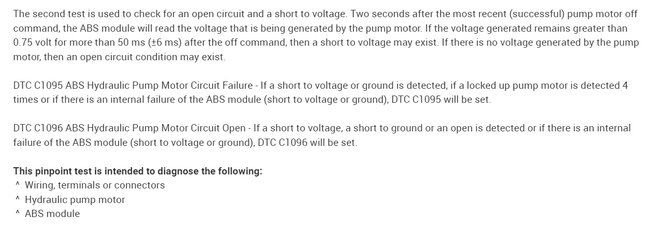

The reason I ask is if the Can High line is the one shorted to ground, pin 6 will read 0volts and pin 14 which is the Can Low line of this 2-wire network will read something a little bit higher, not much but it will be 0.3 to 0.5 volts because of the Terminating resistor in the circuit. If it's the opposite, pin 14 Can Low is shorted to ground, it will be reading 0volts and pin 6 Can High will read about 0.2volts. If we can determine which of the two wires is the actual shorted one, we can start following that wire. There are some splices and I'll post the diagrams showing you what I mean, and possibly find if this is a shorted wire, or if it's a module that has a short in it. Some modules we can get to easily enough such as the ABS module, the Turbocharger actuator, the PCM, we can unplug and see if the short disappears.

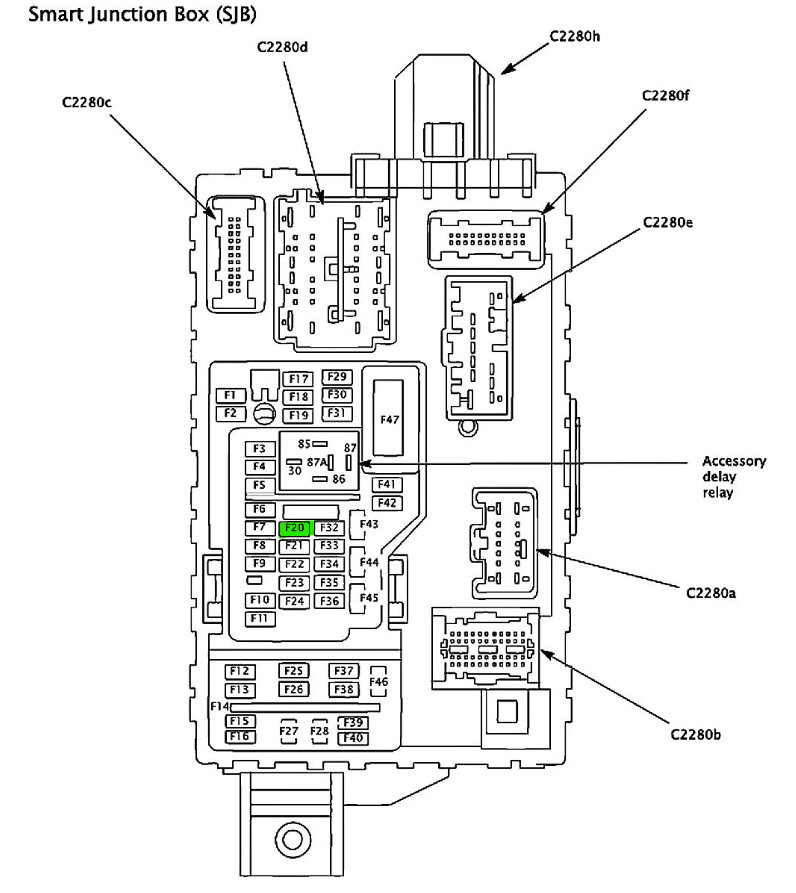

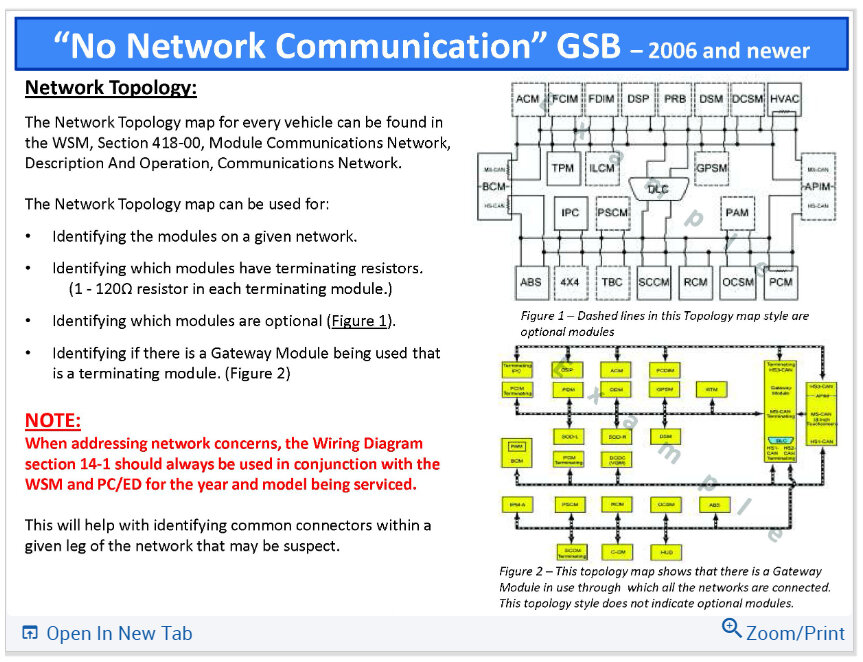

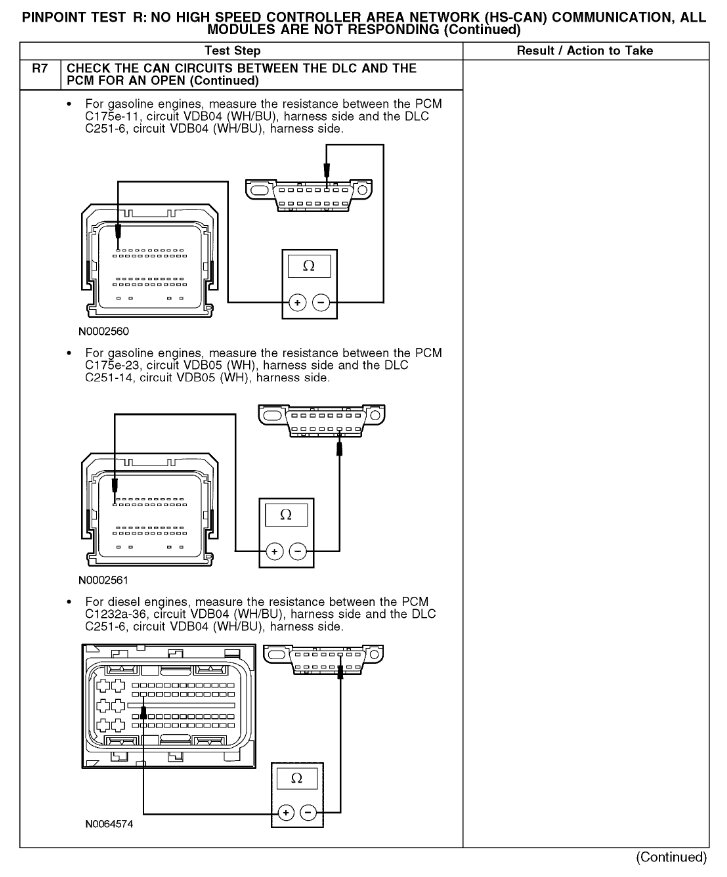

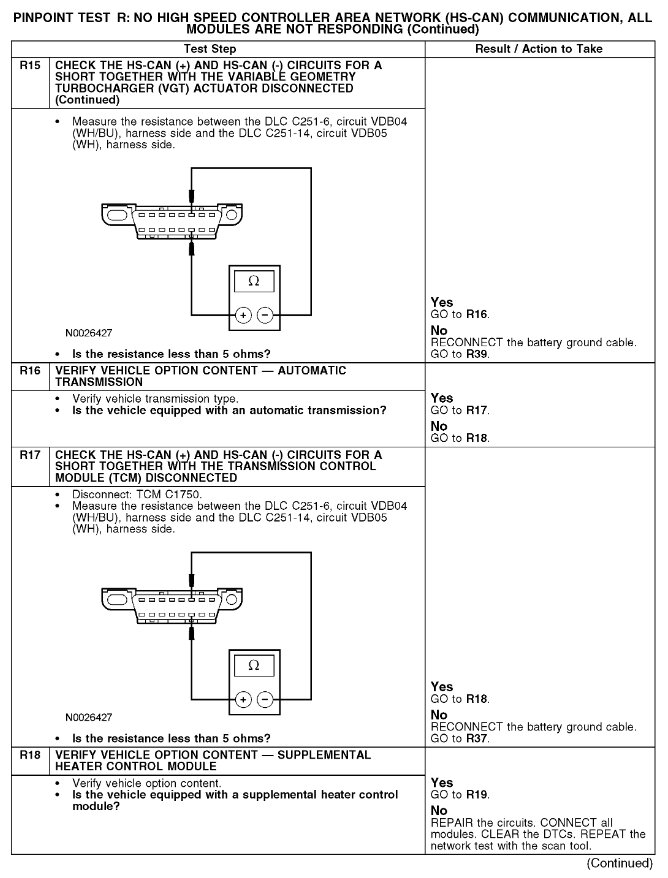

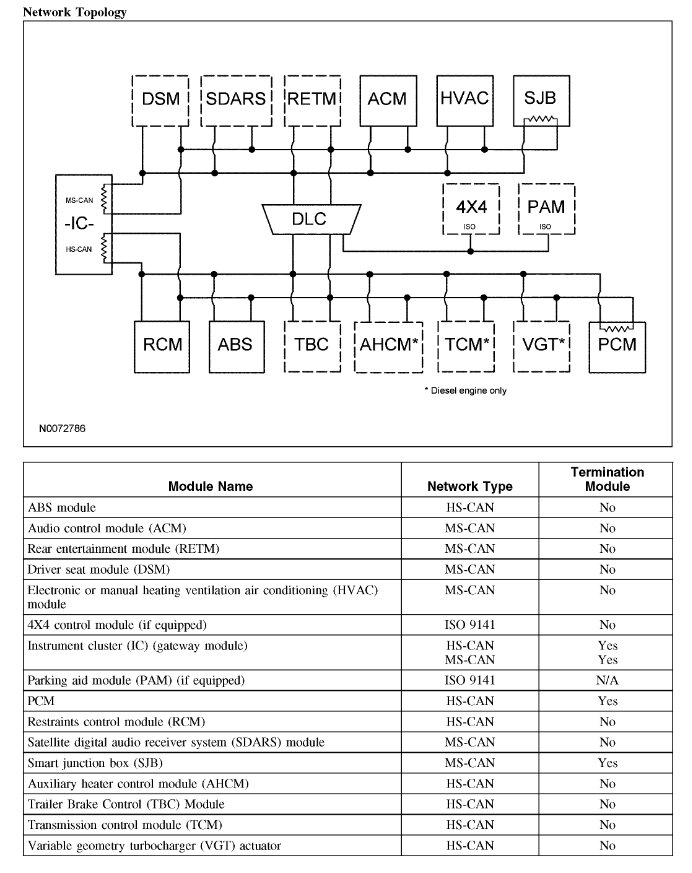

And if we can't get anywhere with that, then you can start going through the flow chart. The diagrams 2 and 3 below are the high speed can come from the DLC you can see on the left of diagram 2. Pins 11 and 2 are the Medium Speed can bus, so it appears that it's only the High speed that is down. You were not able to communicate with the ABS module either I assume. So, we can try that if you want, those two network wires are the same color throughout the entire truck.

When you check at the data link connector, back probe the connector if you can so the pins don't get spread, since you'll have to have a meter lead hooked up to it for a while, unless we back probe the PCM connector. But start with getting a voltage reading for each pin and then disconnect the negative battery cable off and do a resistance test on pins 14 and 6 to ground. Maybe we can make this a little easier on you.

Images (Click to make bigger)

Saturday, October 8th, 2022 AT 6:37 PM