Ok. So my cable went down the day before I fixed

what it was this whole time!

I was correct the whole time!

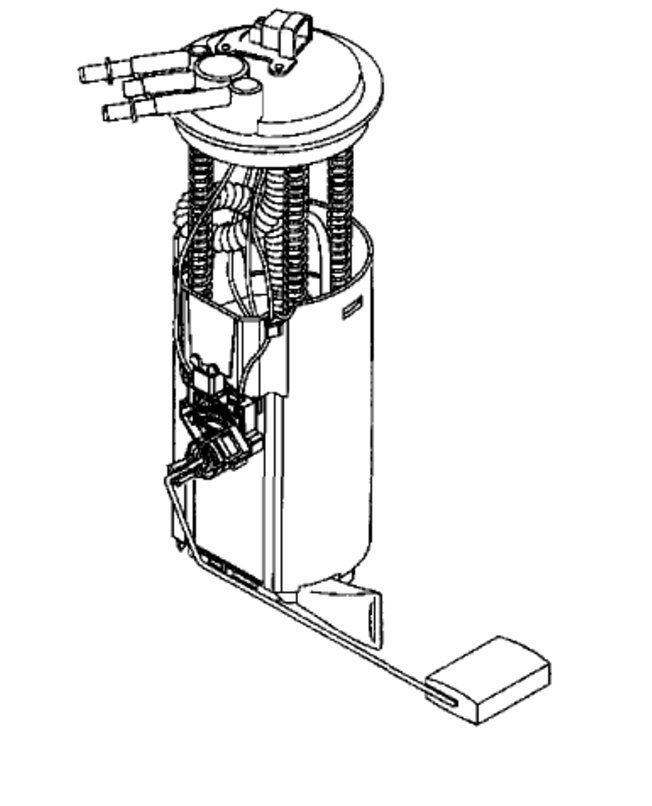

Fuel pump. FUEL PUMP! OMG! DAM FUEL PUMP!

Ok, I did EVERYTHING to the POS before I changed the

Fuel pump. As the following.

Computer numbers always first.

Cats, Plugs/Wires/cap/rotar, Fuel filter (changed)

Air filter, Idle control Censer, Vacuum lines,

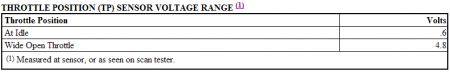

Throttle body censer, Fuel pressure regulator (Changed)

EGR Valve cleaned, Fuel line cleaned, Top Manifold Cleaned,

im sure there is more I did to it. 3-4 months of checking,

Fixing things and all along I knew what it was.

But everyone was trying to stay away from what it was.

After many hours and money. FUEL PUMP!

Symptoms =

Starts up fine, NEVER ever starting issues!

Cold start - Idles fine, Takes off fine, Driving

and it starts to get less pressure = loss of power.

Then it will act like theres no fuel no power, then

as letting off the gas the idle is fine!

I hope this helps anyone else with the issue of the

Chevy (Tahoe) aka POS on this issue.

Saturday, August 11th, 2018 AT 7:29 PM

(Merged)