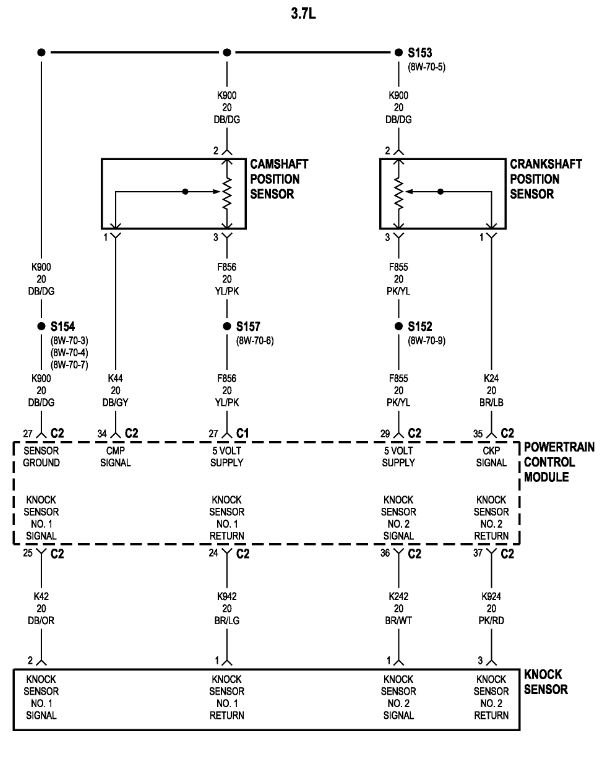

I'm getting a p0339. I got it initially about a month back, and then it went away after I replaced spark plugs and a melted ignition coil. But, it then came back when my truck broke down about a week and a half ago. You can see my previous questions to see exactly how I broke down, what happened and such. I drained the oil because my oil light came on. My oil looks perfect. My father said that a bad crankshaft sensor could cause all of it, and he said that the crankshaft sensor could be the reason I also now am getting p0344.

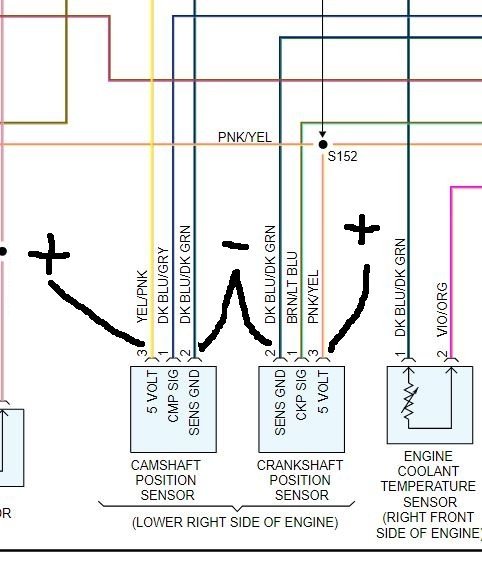

I only got the camshaft p0344 the second time I got the p0339. So this camshaft sensor code is recent, my father recommended replacing my crankshaft, clearing the codes, and seeing if the camshaft comes back. But, I am stuck with the crankshaft sensor in there. I have it twisting freely, counter clockwise and clockwise, and I have very very slight movement back and forth. But no significant movement outwards

Can you confirm anything he said? Thank you

Happy holidays Steve!

Friday, December 20th, 2019 AT 10:26 PM