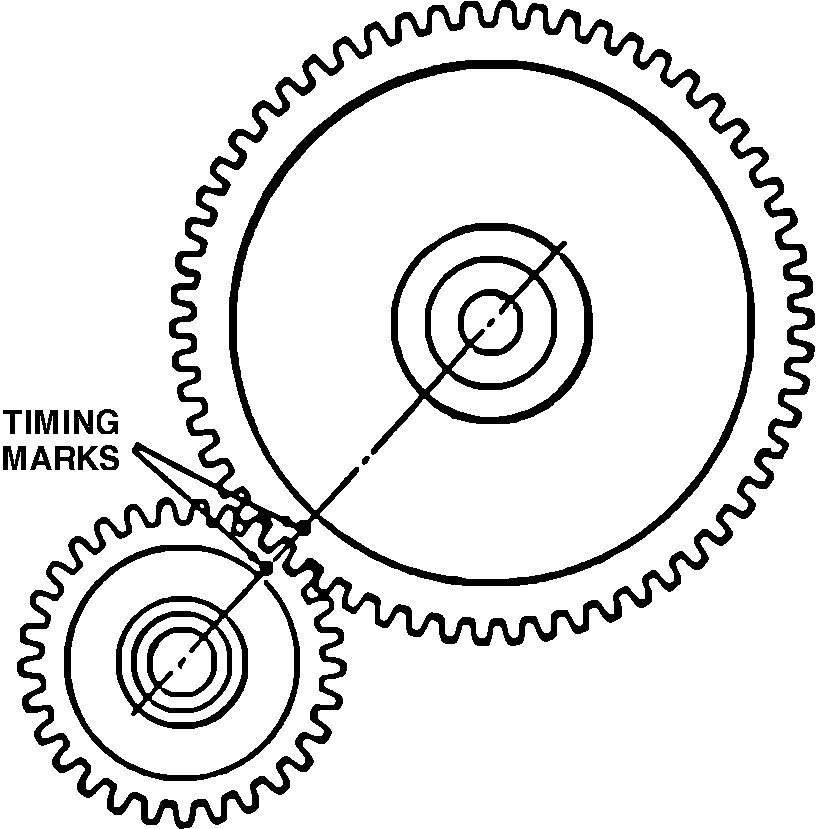

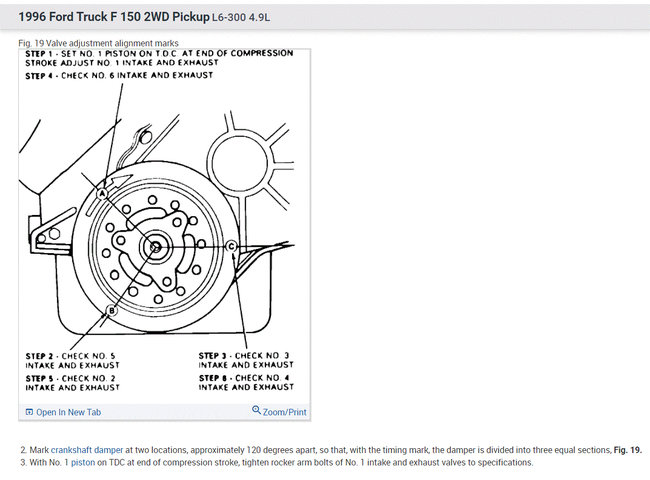

This is my first time rebuilding an engine myself. Even though I got the timing marks, on the gears, aligned and it makes a straight line between the two shafts, I am still not confident on the timing, in general. Particularly with the lettering being upside down on the crankshaft pulley when you hit it with the timing light. I sent you a still picture, of the timing marks with the video so you get a reference to where the timing was hitting, on the pulley, because it was hard to see the lettering on the video. The pointer from the crankshaft sensor bracket is landing on the 10-12% BTDC. To my understanding, this is where it is supposed to be.

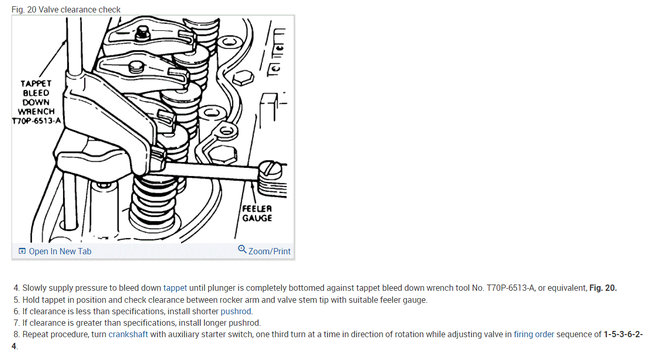

There is a clicking sound coming from the engine. I do not know where it is coming from.

I erased the error codes before I reassembled everything back together. I have not given the engine enough time to display any code. I only ran the engine for a minute or two.

I can double check the vacuum line. I have had to replace them everytime I run the engine for more than 5 mins. Because of the heat.

Let me work on checking the exhaust manifold for blockage.

The primary purpose of this project was to learn engine rebuilding. I just wish I had chosen a smaller engine to work with. I do not mind starting over but at some point I need to make a Lowe’s trip. The secondary purpose for the truck.

Monday, June 21st, 2021 AT 5:29 AM