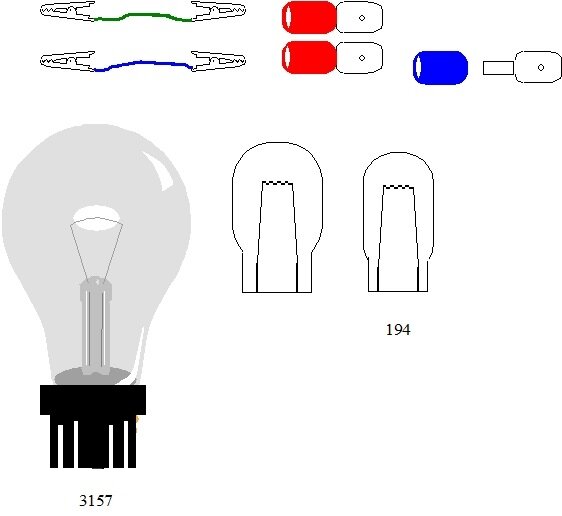

On your first photo, I've seen those too, but never really paid much attention to them. If that is one wire feeding two fuse link wires, the two will be of a smaller diameter for up to about six inches, then there will be another splice and the wire will go back to a larger diameter. That makes the smaller fuse link section the weak link in the chain. The insulation on fuse link wires is dull, and chances are it will be a different color. Their current ratings are denoted by the color of the insulation, and I don't think I've ever seen red. Orange, gray, white, and black are common. The wire is regular wire. It's only the insulation that is special. It is designed to not burn or melt. If the two wires are red and shiny, it's more likely they're just two different circuits. It's less expensive to use a splice rather than run both wires all the way back to their point of origin.

You purchase replacement fuse link wire from any auto parts store. You'll get a piece about 12" long which is more than enough to make two or three repairs. The length of the installed section is not important. All that is important is there is something in there that's smaller than the rest of the wire it protects. In fact, you can splice and solder the ends of the old fuse link together too to make the repair once the short is solved. As long as some of the original wire is still there, the circuit is still protected.

As a point of interest, you can harvest a whole handful of fuse link wires at any salvage yard from an older Dodge Shadow or Plymouth Acclaim, and their twins. Those front-wheel-drive vehicles have about a dozen of them in a bundle running around the left front strut tower under the hood. Typically you'll see mostly white and a couple of gray wires.

As long as I'm sharing all this wondrous information about fuse link wires, these are used in high-current circuits, and they act like slow-blow fuses because they take some time to burn open. Current flow through a motor goes way up when it is stalled or locked up, or runs slow due to tight bearings. That will cause the link to burn open eventually. A motor that's just starting up when power is first applied also draws high current for a couple of seconds until it gets up to speed. That's where a regular fuse could blow but there's no actual defect in the circuit. Fuse link wires tolerate that momentary high current.

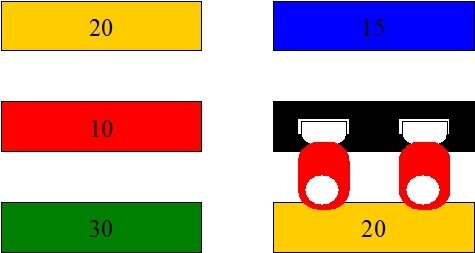

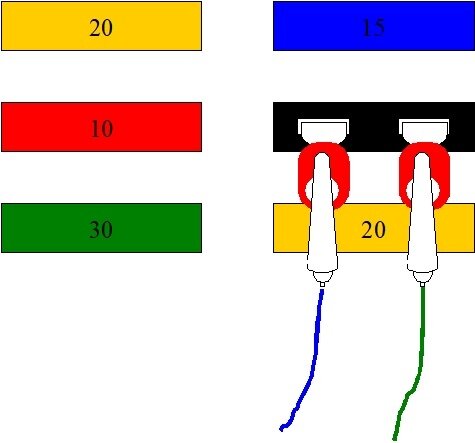

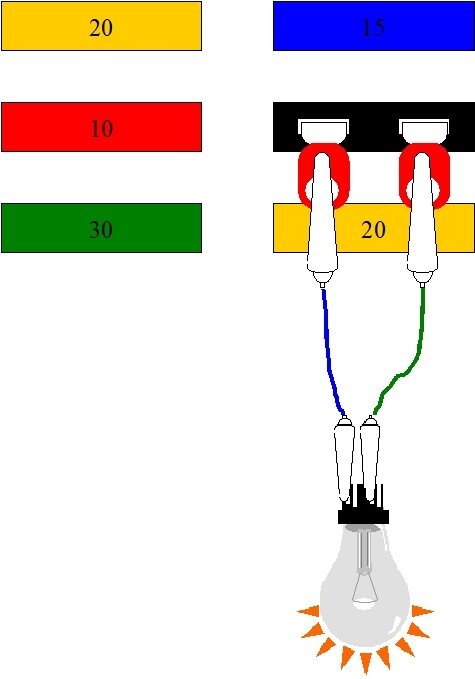

There is one huge drawback with fuse link wires that isn't an issue once you understand what is happening. In one case in particular, a very experienced former coworker who didn't like me, came over with his tail between his legs and asked for my help years ago with a radiator fan problem on a K-car. The old fan motor had tight bearings, so he ordered a new one. Couple of days later he installed it but it wouldn't run. He used the scanner to cycle the fan's relay on and off and found 12 volts pulsing on and off on the motor's positive wire. Ground wire was okay. In his mind he had ground, 12 volts, and a motor that runs when he jumps 12 volts to it, yet it doesn't run in the car. All I told him at first was to recheck the 12 volts with a cheap, standard test light instead of his expensive voltmeter. He looked confused, but came back a few minutes later and said now he does not have 12 volts pulsing on and off, and he found the fuse link wire burned open. He was my buddy after that. There was nothing wrong with his diagnosis, except he didn't go far enough.

Digital voltmeters work by measuring electrical pressure, (voltage). To do that, it takes just barely a tiny tickle of current to do that. The drawback I started to describe about fuse link wires is when they burn open, the last step is for some arcing to take place between the two ends of the wires. That arcing leaves a carbon track behind on the inside of the insulation, similar to what we often found inside distributor caps. That little film of carbon can pass enough current for a voltmeter to see 12 volts at the end of the line. Think of having 50 psi of water pressure at a faucet and at the end of the garden hose. That carbon track would be like standing on the hose and blocking it by 99 percent. You'll still have 50 psi at the nozzle, ... Until you open the nozzle and try to get some water flow, (current). Barely a dribble of water will get through, and now, with the nozzle open, you don't have 50 psi there anymore.

What would have made the K-car problem faster to find was if he had taken the voltage reading with the connector plugged in. By unplugging it, that was like having the hose nozzle closed off. Full pressure will still be at the nozzle as long as you don't have the hose 100 precent blocked with your foot. That 50 psi is a false reading. It isn't there when you want the system to do some work, in this case, spray water. The 12 volts he had at the motor's connector was there until he connected it to the motor and tried to get enough current to do some work, then it was gone.

The old-style, common test light with an incandescent bulb inside requires current flow through it to do its thing. Not enough current can get through the carbon track to make the test light turn on, so it gives the more accurate result.

This applies to any high-current circuit like heater fans, head lights, charging systems, wipers, and things like that. Besides just checking to see if you have the required 12 volts, you must also see if the circuit can pass the needed current. There's two ways to make it want to draw the required current. One is to simply plug in the item it runs. That was the radiator fan motor in my sad story. That's the time to take the voltage reading, but in some cases that can be hard to do. Being plugged in to get valid readings also applies to sensor circuits. With those, there's usually rubber weather seals around each wire where they go into the connector body. That's a perfect place to poke the meter's test probe. Radiator fan plugs are designed to seal out water when they're connected, but if you're careful, you can usually pull them apart just enough that they stay connected, but enough of the terminal is exposed to allow you to take a reading.

So keeping the circuit connected is one way to see if it can pass enough current. The second way is to use a test light instead of a voltmeter. Test lights don't draw nearly as much current as do motor's, but they at least draw some. Voltmeters draw so little, for all practical purposes, we say they draw no current.

In your second dandy photo, you've created the mechanical connection I described. The solder will provide the electrical connection next. When I do door wiring, I don't even twist the strands together. I prefer to just slide the strands from both wires into, or through each other, twist them just enough so they hold together long enough to throw some solder on them, then I slide the heat-shrink tubing over and warm it. I'm less concerned with the solid mechanical connection because when I do these on older Caravans, it takes 11" of wire, but I pull the old wires out of the "A" pillar and out of the front of the door, then splice in 22" of each new wire. There can be up to 22 wires if the van has door speakers, courtesy lights, power mirrors, and things like that. When I'm done, I push the splices inside the front of the door where they aren't going to flex. Half of what remains gets stuffed inside the "A" pillar, but you gotta watch that it doesn't coil up on the parking brake assembly. That puts those splices inside too where they won't be flexing. If that repair ever needs to be done again, you just pull the extra out of the "A" pillar and you're half done. Only have to cut and splice on the door end of each wire.

I also got a chuckle out of your comment, " I'm more of a hands-on learner than a book learner.". In my three miserable years in college, one of the very few things of value I learned was that different people learn best in different ways. I knew that already, but needed to hear it from someone else to solidify my thought. Years later I used that comment in my classroom when explaining why electrical theory and suspension and alignment theory are so difficult to learn. It's because people in Automotive classes, carpentry programs, and other hands-on programs typically learn best by taking things apart, manipulating those parts, and seeing how they interact. People good at Electronics learn best by hearing descriptions and visualizing theoretical concepts. A confused Automotive student, simply made aware of why electrical theory is so hard to learn, finds it a lot easier after knowing why, especially when I can compare anything electrical to water flow, which is something we've all seen and played with. We had to have our book learnin' too, but if you did that the night before, you had questions the next day in class, and that formed the basis of our "class discussions" before we went out to the shop for the day.

I have to add one more comment of value. In nine years of teaching Automotive, three of my top students were girls, and the guys had a lot of respect for them. I don't know if they just tried harder than the guys who grew up in the field, but one in particular would run you over with enthusiasm when she was given a job to work on. We had a lot of fun in our shop.

As before, keep me updated on your progress, and bring on any other questions.

Saturday, October 7th, 2023 AT 6:00 PM