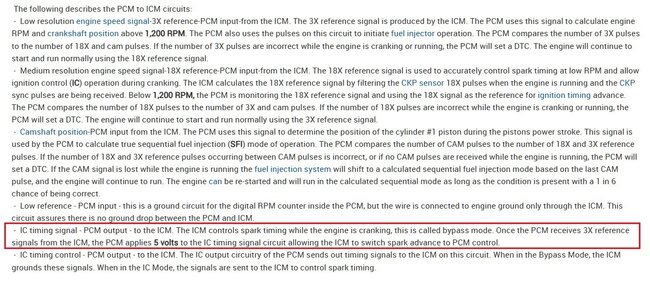

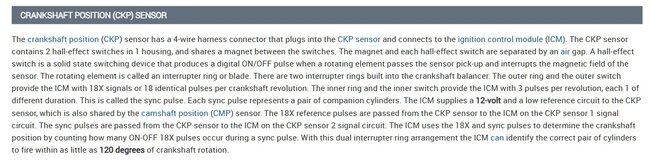

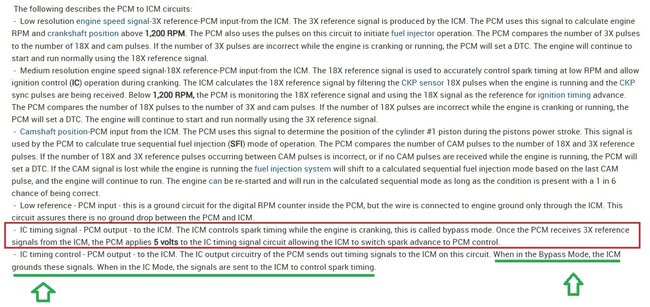

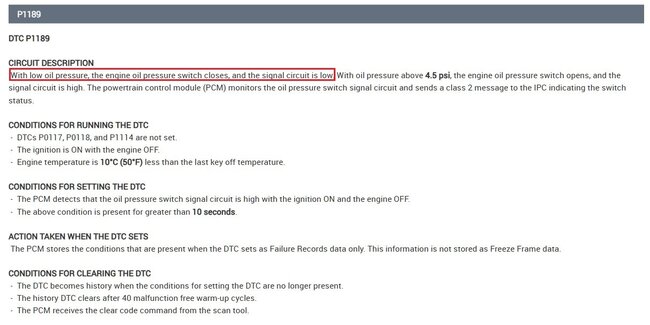

The 18x pulses to Cam signals received by the PCM equal 36:1 ratio.

The 18x pulses to 3x pulses received by the PCM does not equal 6:1 ratio. And it states that the engine should continue to start and run using the 18x and camshaft signal PCM inputs only.

I wouldn't bother checking for any AC voltage signals, because there shouldn't be any involved here and it's just going to confuse the matter even more.

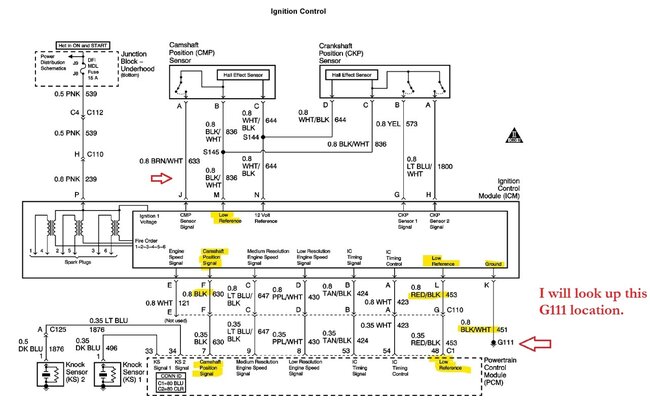

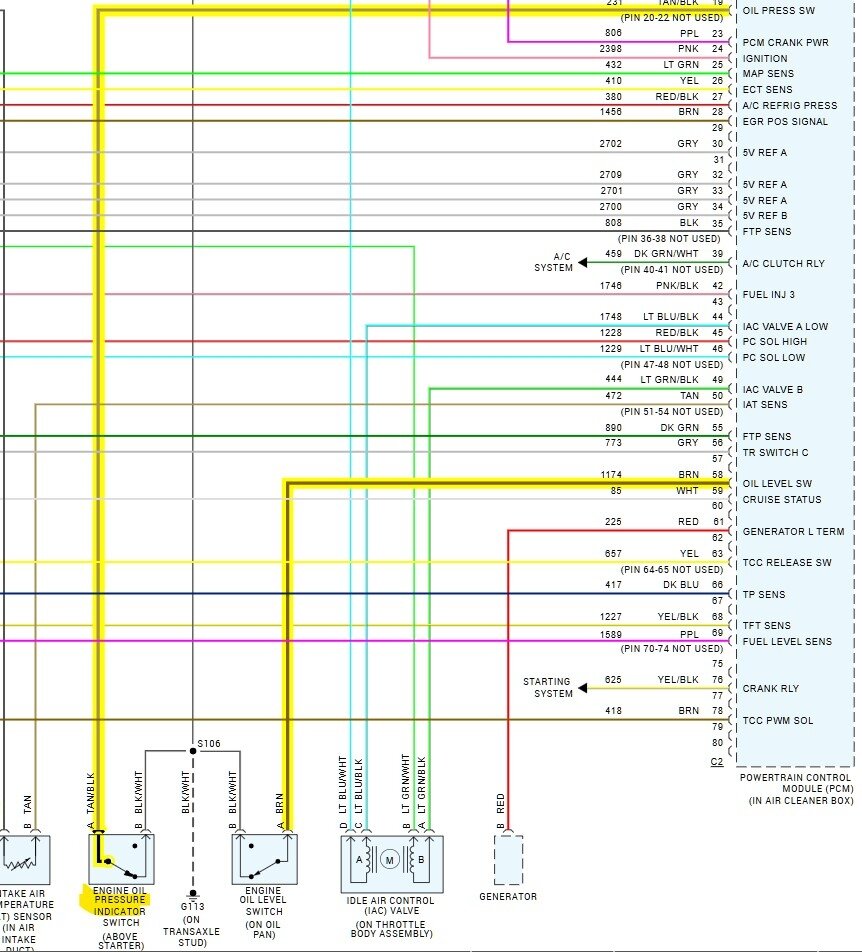

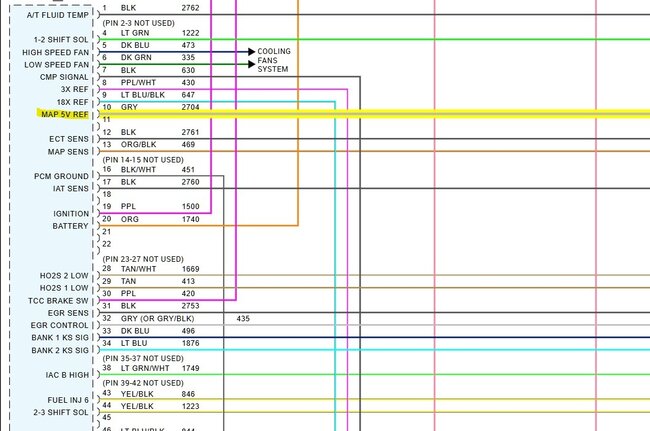

I know this system is confusing because the cam and crank signals are not directly fed to the PCM, they come through the ICM first. The Low Reference wire is stated as "providing a Ground circuit for the digital RPM counter inside the PCM. But the wire is connected to the engine ground only through the ICM. This assures there is no ground drop between the PCM and ICM". Those are the exact words from service info.

The scratch test shows the ICM can generate a 3x signal, but the question is, is that signal good? If you did see a cam signal in the past when the engine was running on your scan tool and now you do not, and your voltage test is showing the cam sensor is not dropping to ground, that is a concern.

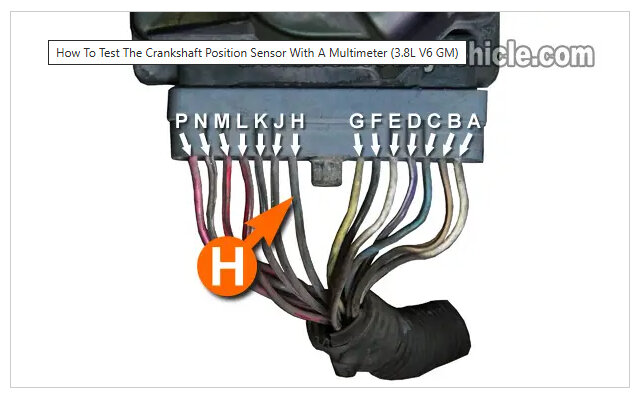

Given that the engine should still be able to run with the 18x and cam signal alone during a fault, I would check the cam signal at the ICM on pin J Brown/White wire is the Cam signal wire coming into the ICM, if that is reading okay, and it's not okay coming out of the ICM, then there might be a grounding issue with the ICM, I would load test the grounds in that case, using a higher amperage bulb with the ICM and PCM disconnected so you are just load testing the Ground wire from the ICM in reference to battery ground. That might be why the cam sensor is not pulling fully to ground.

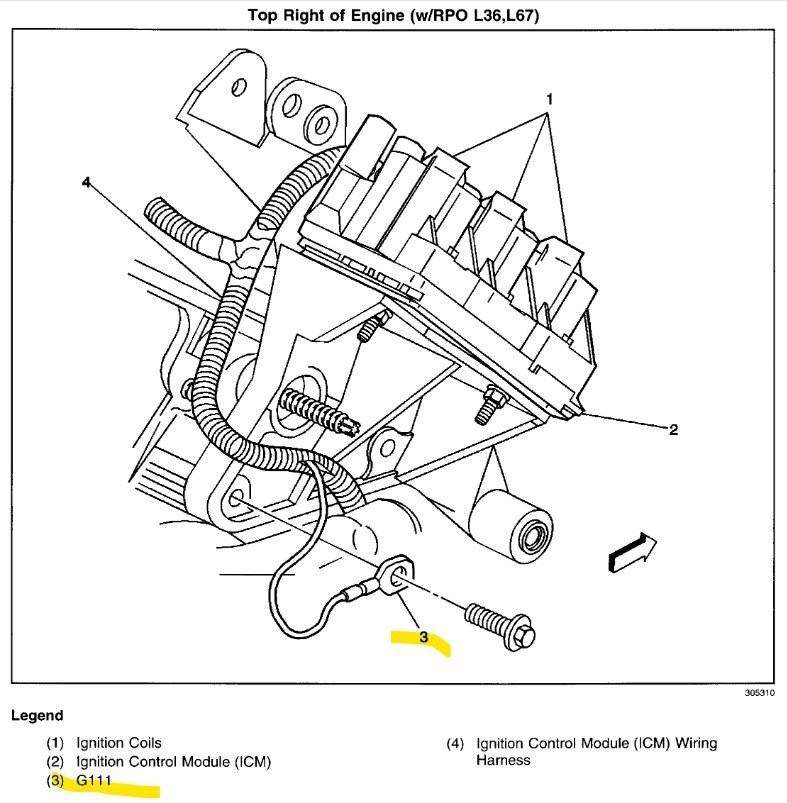

Theres just so much information here on many different signals, it's easy to get lost, but really this is where scope use would come in. You could have checked every signal to make sure it's a good square wave and pulling fully to ground and 5 volts. With a 4-channel scope you could look at 4 signals at once. It would make a huge difference when dealing with so many signals. But I'll find G111 for you. It's probably going to be an engine block ground, but I want to be sure.

Was this helpful?

Yes

No

Wednesday, April 2nd, 2025 AT 2:38 PM