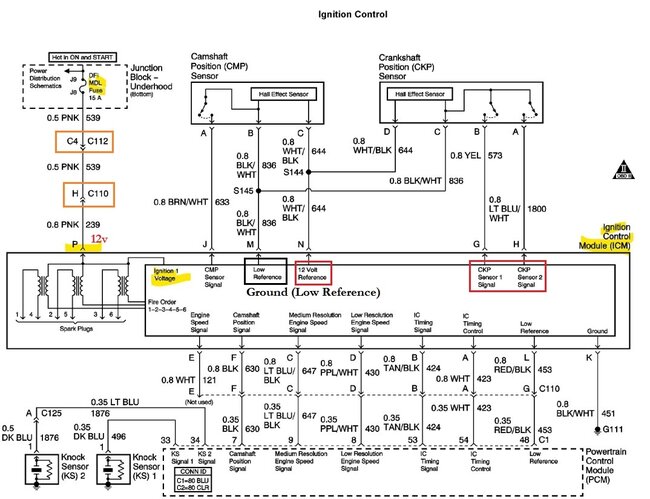

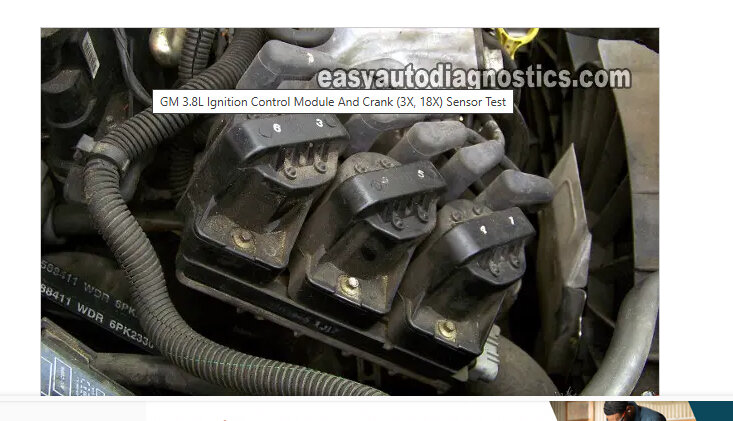

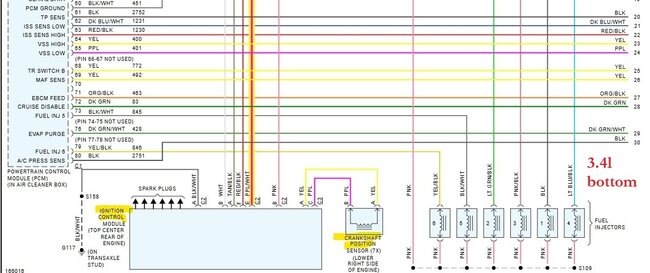

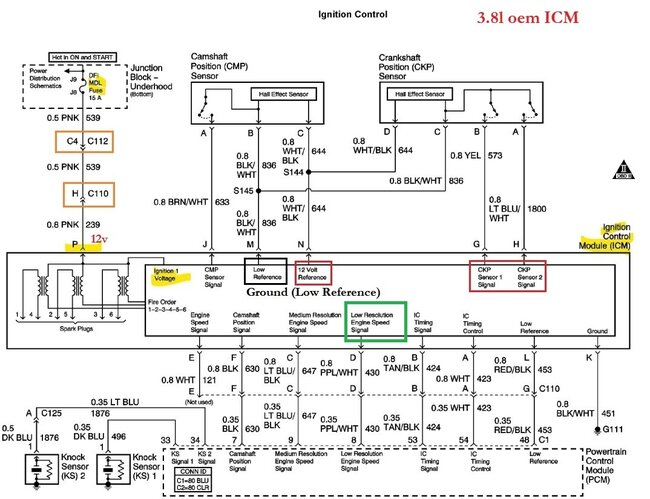

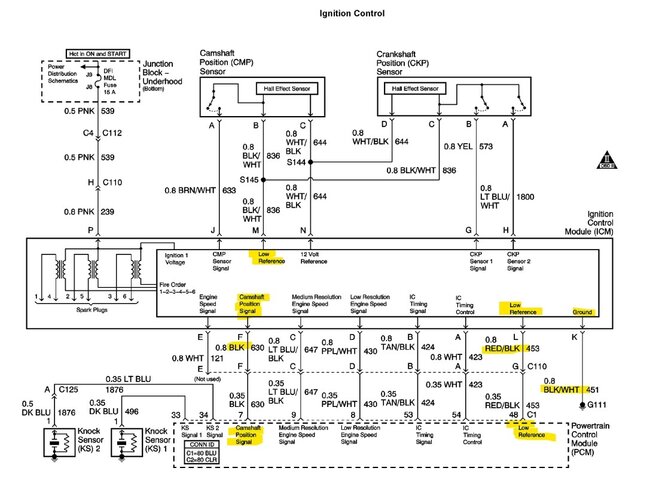

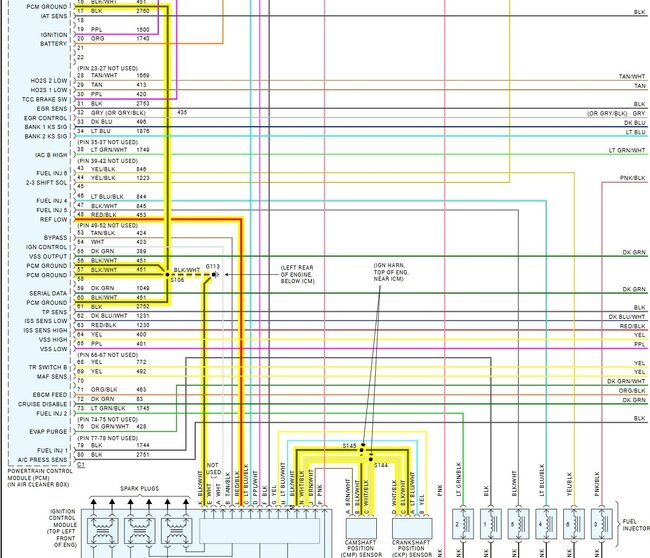

I was told on a mechanic site www. Autocodes. Com that the + spade should have 12 volts key on engine off. My car has less than a volt on all three coils. The 2/5 coil had 18 to 20 mv. The 6/3 coil had4 to 5 mv. The1/4 coil had 16 mv.

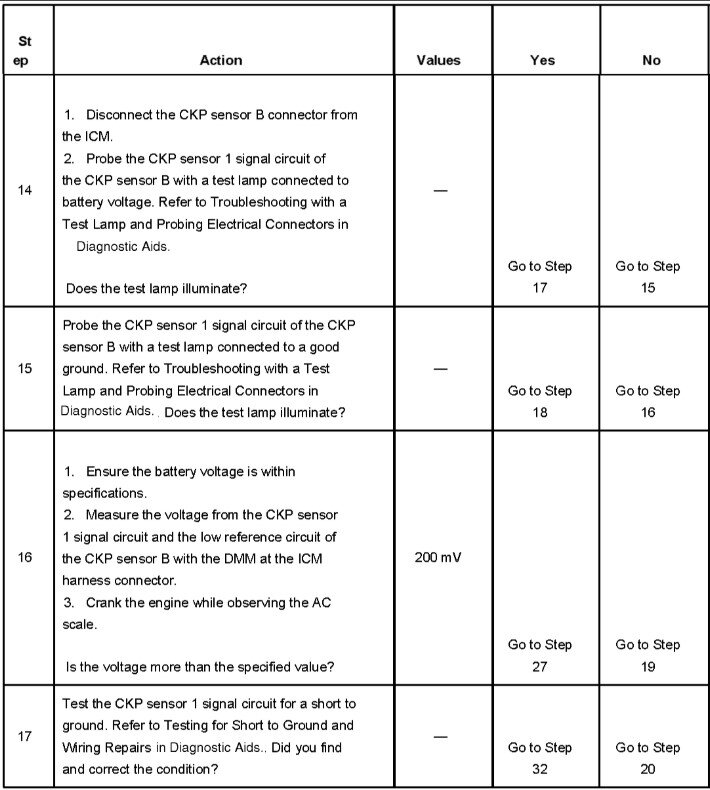

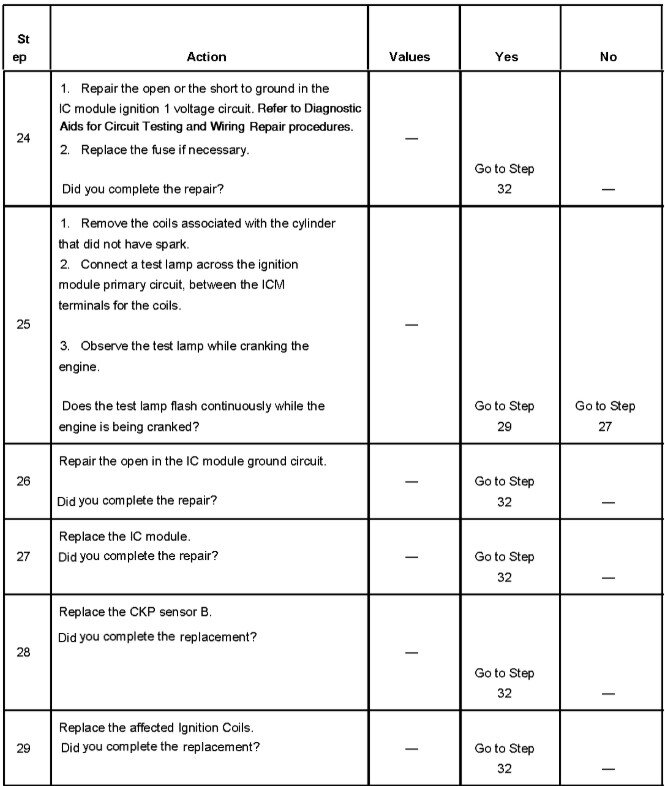

I grounded the multimeter to battery post - post and primary coil - terminal. I got the same readings at both locations. The primary coil - terminals have less.2 ohms resistance or less to the icm case. The icm mounting base has good ground to the block and the battery - post.

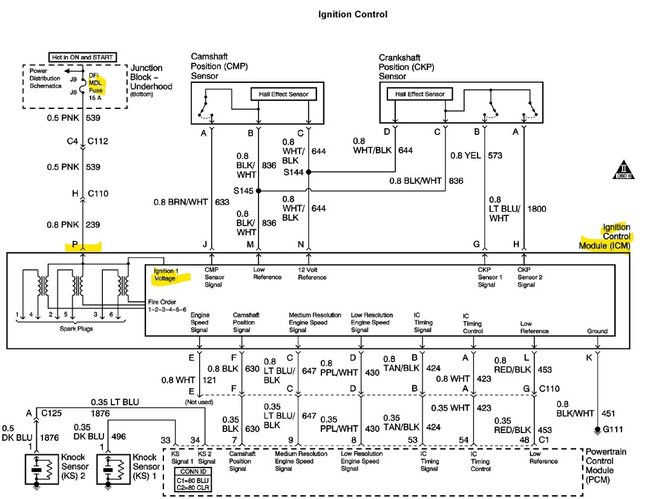

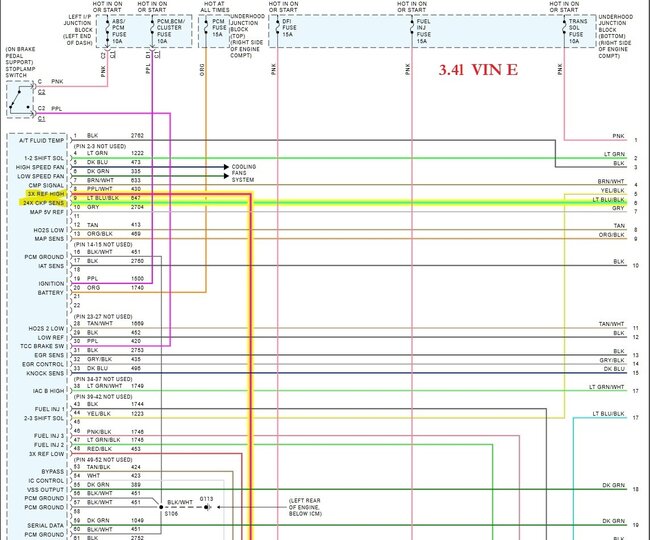

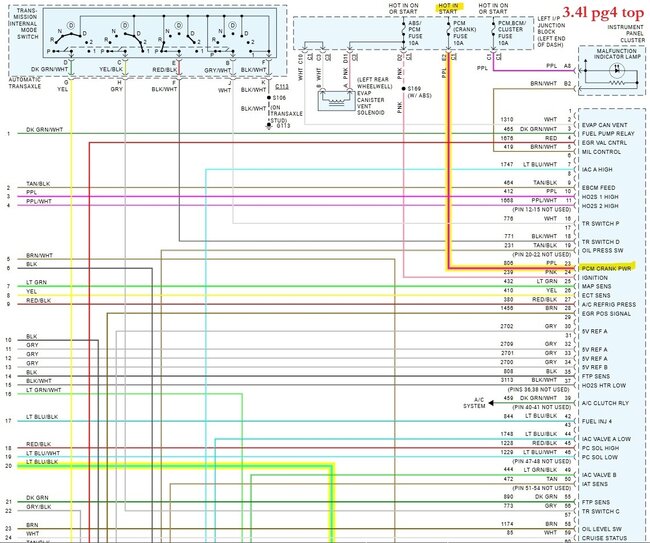

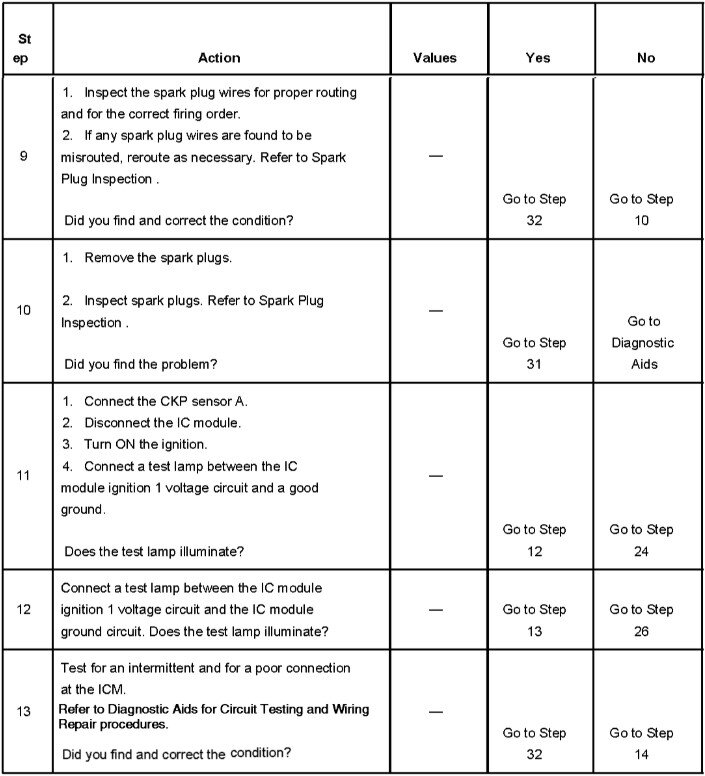

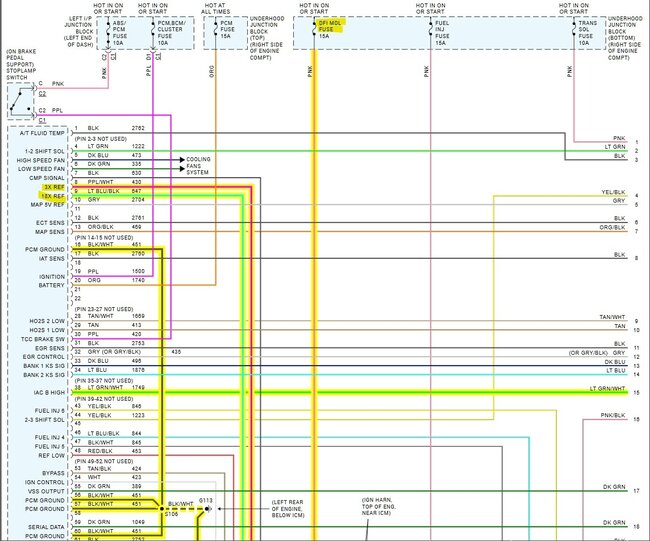

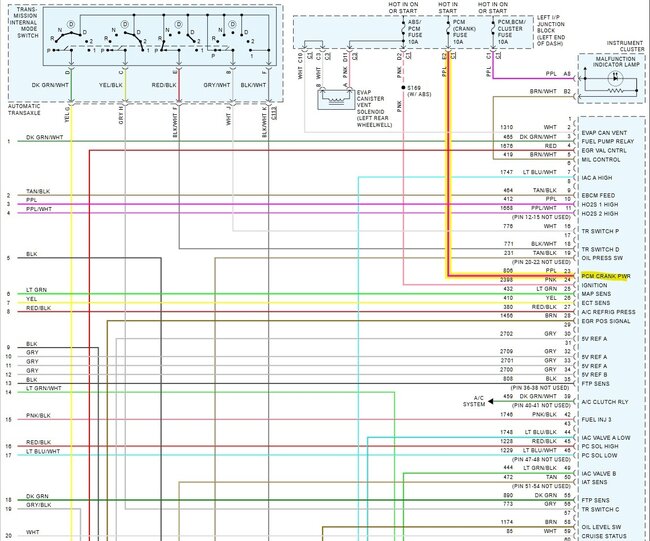

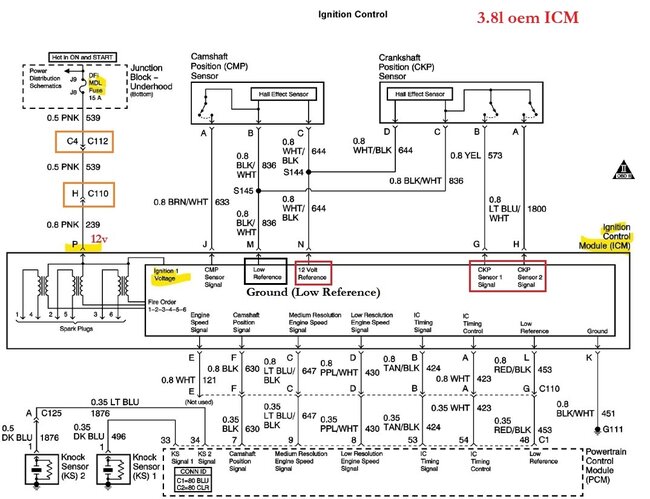

I put my multimeter on the icm harness terminal p pink power and terminal k black/white ground wire which goes to the block and got more than 12 volts. I loaded the circuit with a test light and got over 12 volts. I was told the pink wire feeds the coils.

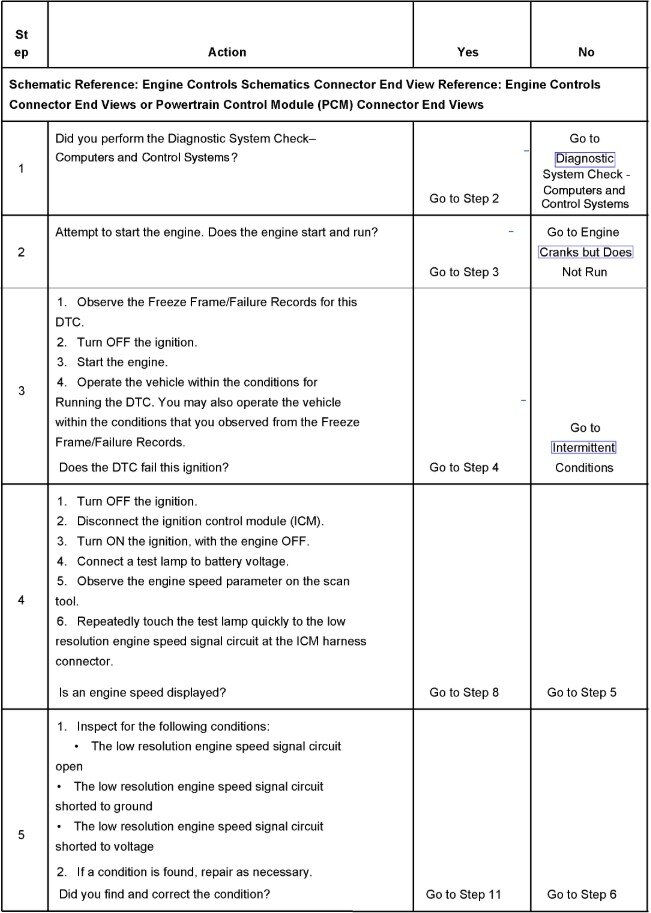

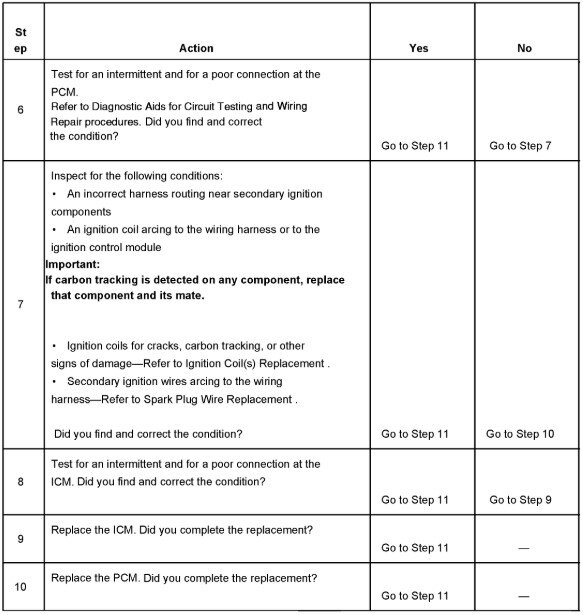

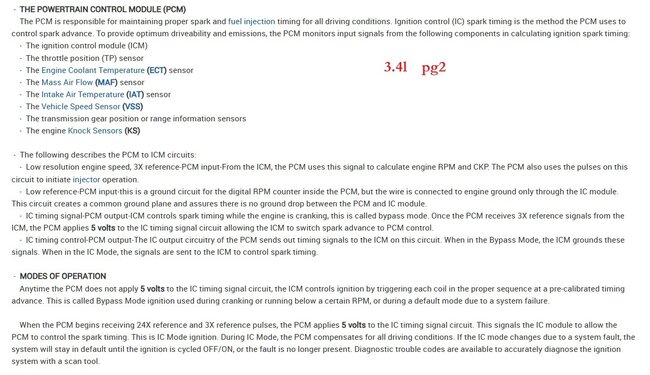

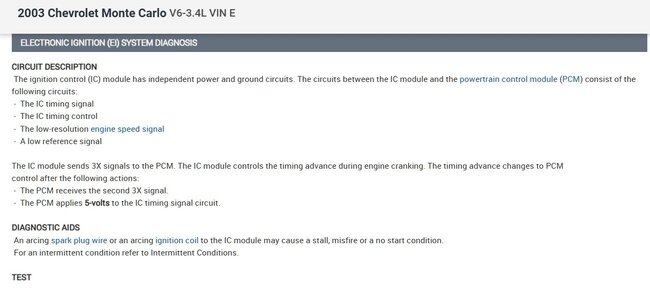

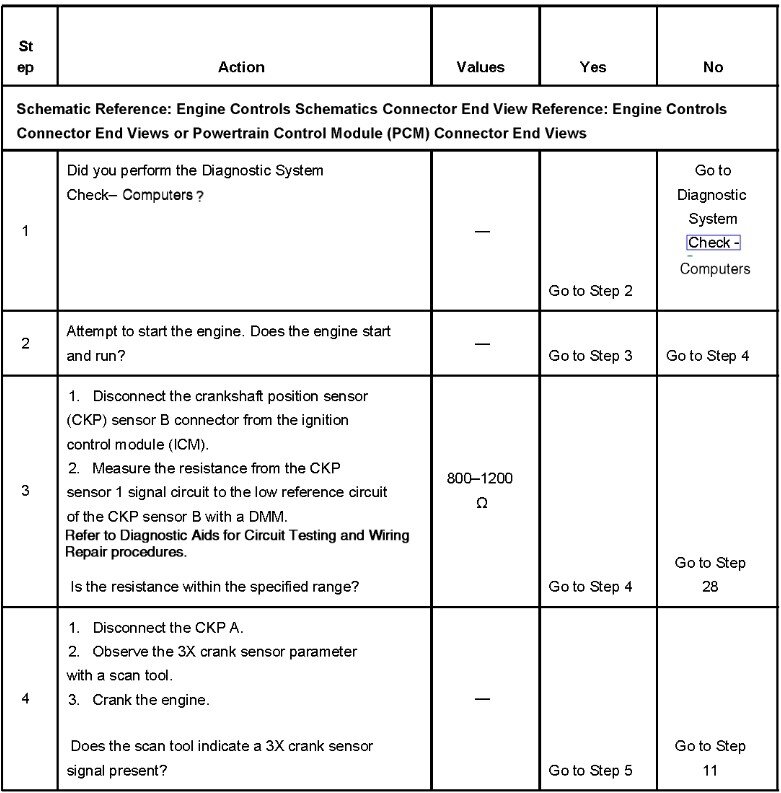

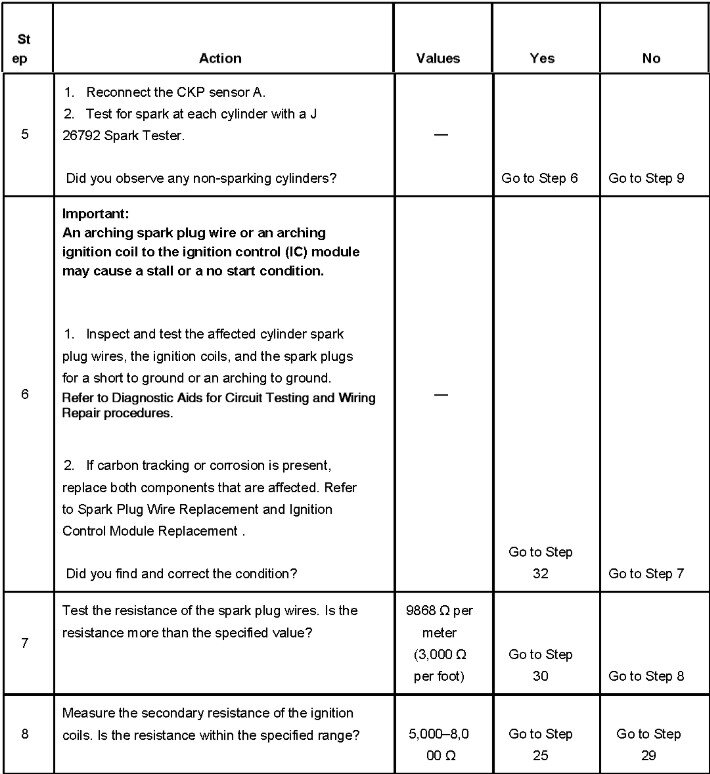

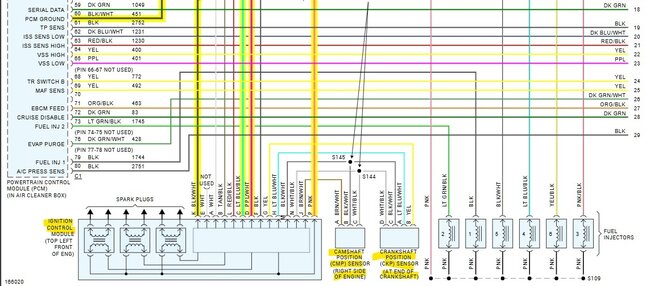

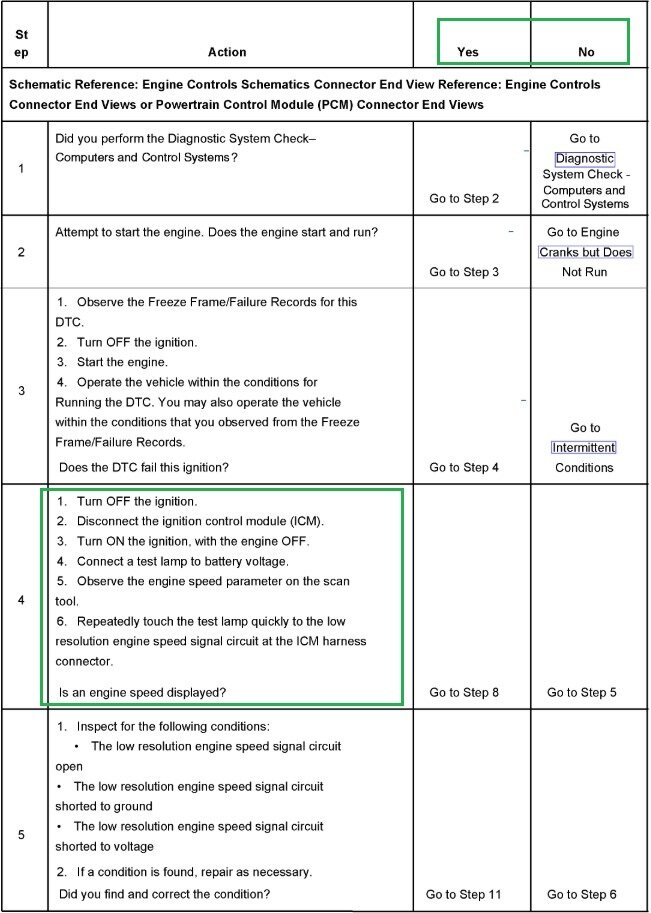

All 3 coils have no spark. I put my test light to battery post + and primary coil - terminal and got a bright light. While cranking the light went out. No icm triggering.

I put my test light to primary coil + and - while cranking, no blinking hence no triggering.

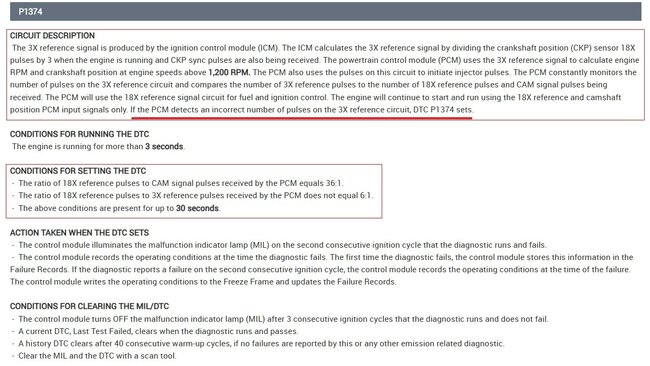

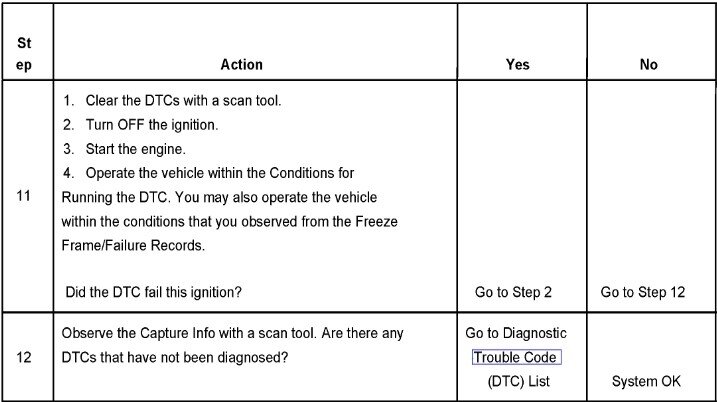

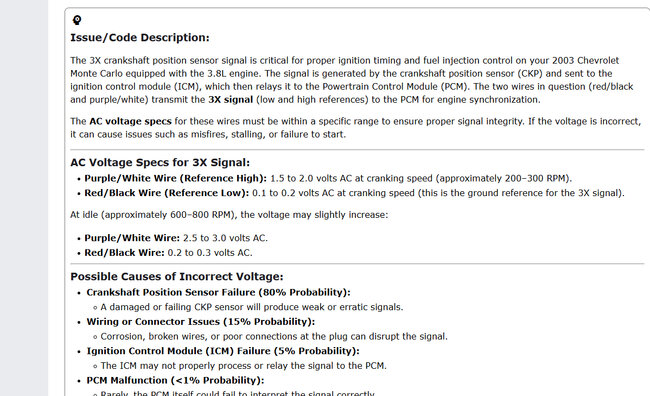

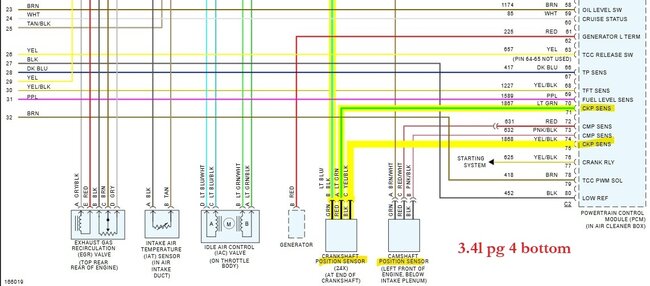

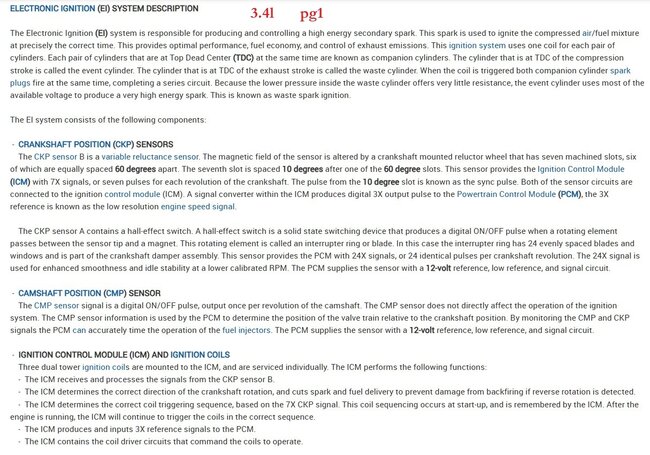

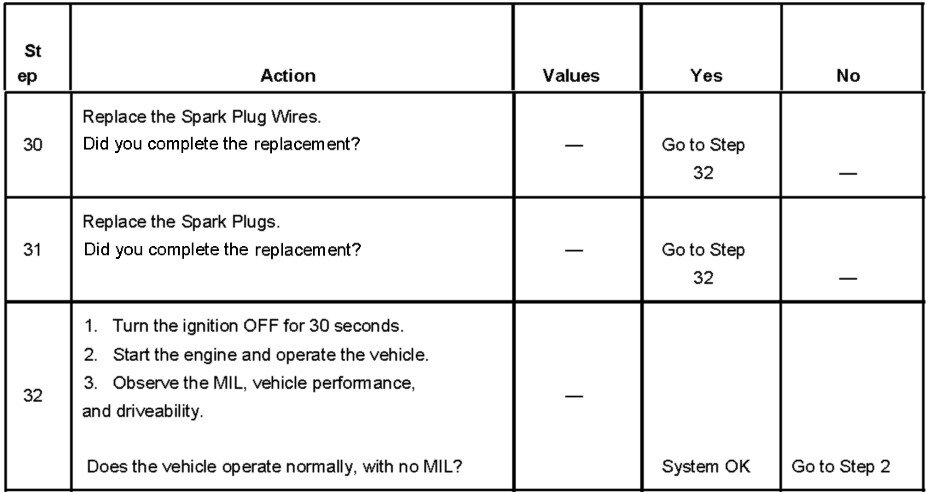

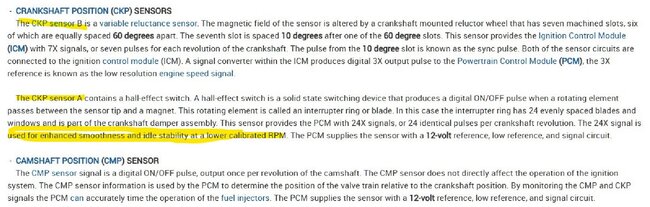

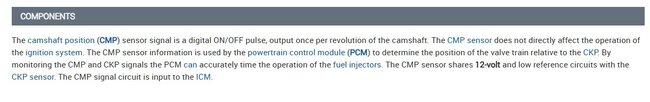

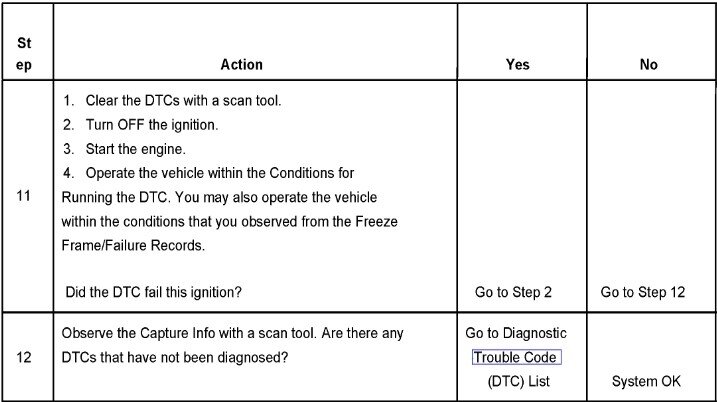

My car was bucking and jerking in park and blowing a little black smoke. Trouble code P/1374 set. Crank sensor reference circuit. 2 days later I had no spark on any coil.

My 3x rpm on my scan tool showed 0 rpm while cranking once and on many, many retests I have a rpm signal.

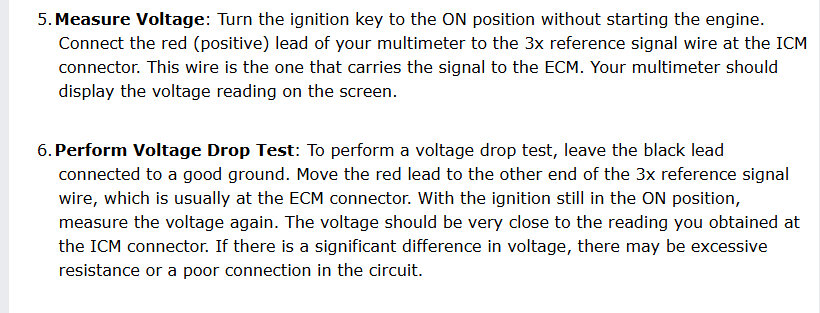

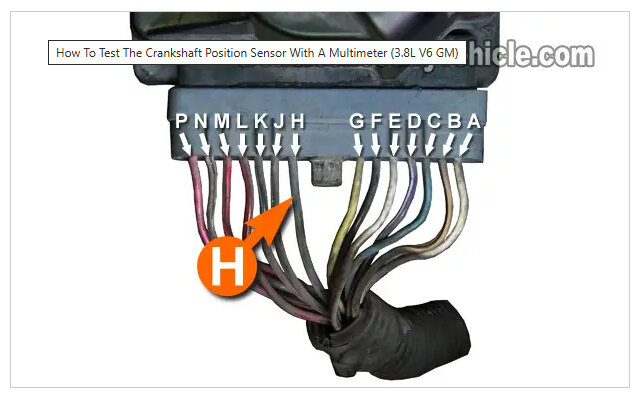

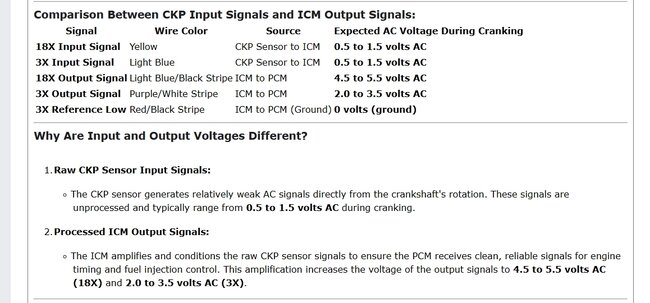

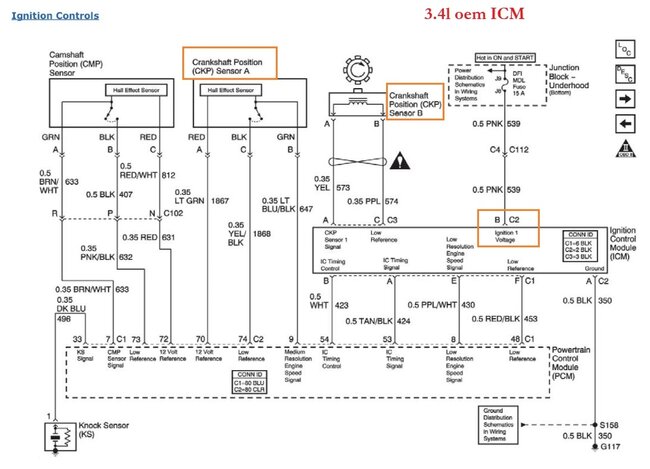

I then measured the 18x crank sensor signal wire going into the icm terminal g yellow wire. I measured at the icm with a multimeter and it shot up 3.5 ac volts while cranking with no minimum voltage. I was told my multimeter is too slow to read it. On the 3x signal wire I got 1.7 to 2.8 ac volts while cranking terminal h light blue/white wire.

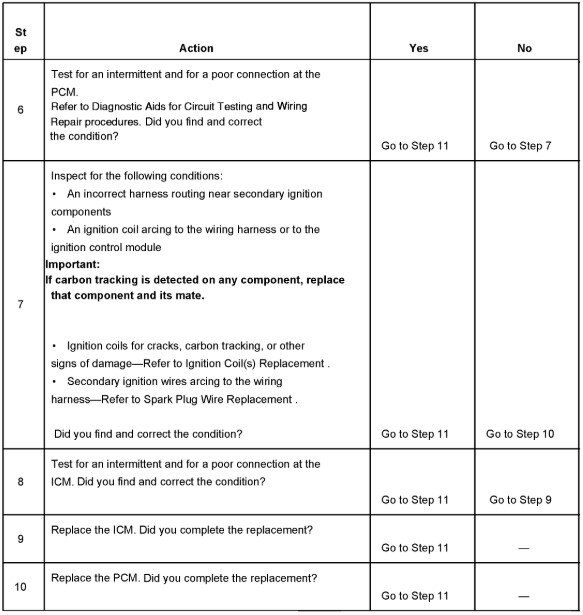

I was told the coil primary - terminal switches on and off to do the coil sparking and the + terminal has 12 volts all the time. It sounds like I need an icm.

I may or may not check my 18x and 3x voltages coming out of the icm. I may or may not turn the crank by hand and measure the crank sensor dc volt outputs. But I all ready have a rpm reading and crank sensor outputs.

To summarize should I have 12 volts on the coil primary + terminal. Key on engine off.

I await your reply. Thanks a bunch, Bruce Duncan

Thursday, March 20th, 2025 AT 8:28 AM