More than likely a replacement fuel level sensor on eBay will be to replace the factory original one. That might not work on an aftermarket pump housing.

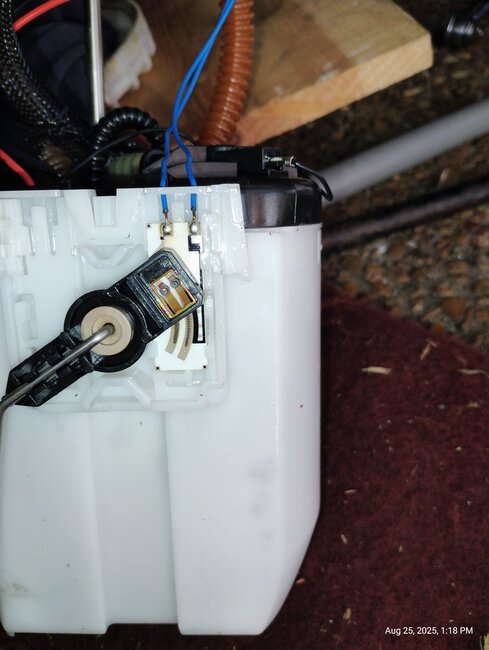

I don't see a common ground wire for the two curved strips on the sensor, so it looks to me like those two copper contacts are tied together. That would agree with the wiring diagram. Those copper strips provide the pressure to keep the contacts touching the curved carbon strips. Those are what need to be bent just a little so they provide more pressure. That would be easy to do if you could pop the assembly off its pivot peg, but often those are made to go on and never come off without breaking something.

The next thing to consider is to see if you can pull the end of the black piece away enough to give room to bend the copper strips down a little more. This is a place where you have to use caution because if you can't lift the black piece up, if you bend the copper strips next to where they're anchored, they'll bend the other way between the contacts and where you're pressing. That can actually reduce the pressure on the contacts and / or move them away from the carbon strips.

My next suggestions are a little radical, and I'd save them for a last resort when nothing else works. One is to pull the end of the black piece up enough to let the copper strips relax, then run a bead of solder on each strip. You'll need to shine them up first with very fine sandpaper so the solder will adhere. Once cooled and you let the black piece go back to its normal shape, the solder will try to hold the copper strips with more pressure on the contacts.

My last thought is to place a light coil spring over the copper strips, then use a piece of wire to hold it in place while putting pressure on the contacts. That would require some experimentation. For this type of project, I tear as many strands of wire as I need for the job from an old power cord. Those are easy to work with, and if necessary, you can solder to them. Heating them next to plastic will cause the plastic to melt and embed the wires, holding them in place. One word of warning here. If you use a soldering iron to melt plastic, set it to its lowest temperature, (if you have an adjustable iron), then clean the tip as soon as it cools. A lot of soldering tips today are iron-coated copper to make them last longer, but plastic residue eats that iron coating off, then the tip will burn away rather quickly. When I want to embed a wire in a plastic piece, I put a strip of copper over the wire, then heat that and let it transfer through the copper. That keeps the soldering iron tip clean.

If you don't mind the extra work, look for a similar model in a pick-your-own-parts salvage yard. See if you can pop the contacts off without breaking anything. If you can do that, bending the copper strips should be an easy solution. Often you'll find someone already removed the pump housing to get the pump, and they left the rest behind for you.

Tuesday, August 26th, 2025 AT 3:00 PM