Tests completed

Fuel Pressure

1) Fuel Pressure (trying to maintain Idle due to surge, stumbling and trying to stall out) was at or a little above 34.

2) Few seconds after Ignition off it read 43.

Fuel Pressure Regulator

The fuel pressure did decrease as I pumped the Vacuum tool connected to the Regulator and engine vac plugged off.

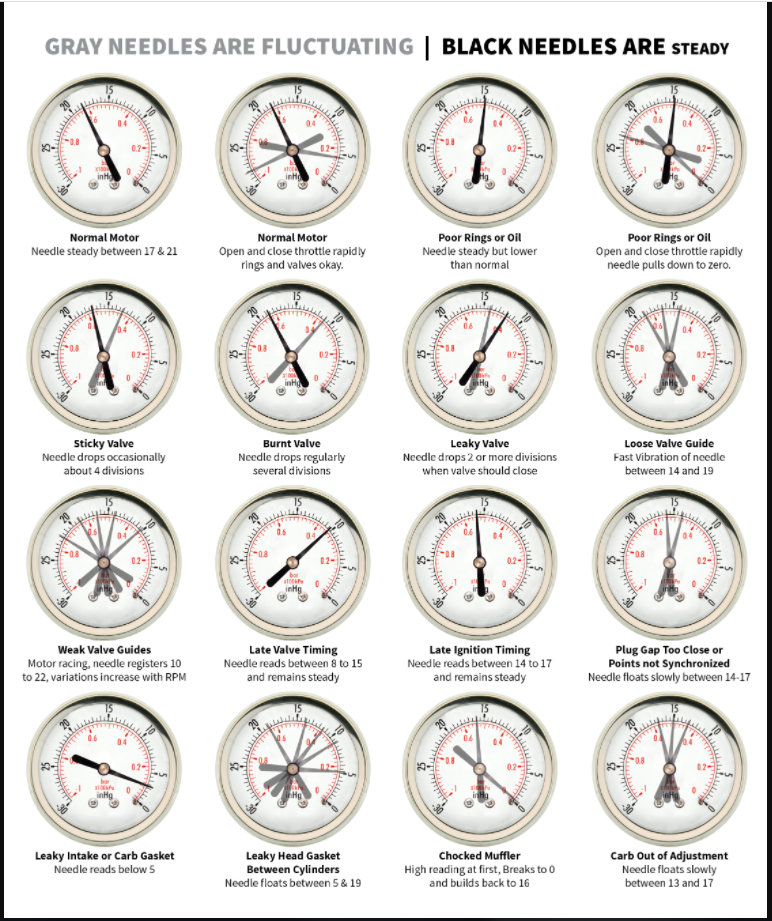

Vacuum Test

Using a T connector, I connected the vacuum tested to line at base of throttle body area and disconnected the MAF sensor to maintain RPMs at about 1500 to 1600 instead of fighting to keep it from stalling out. Read at a steady 19.

Compression Test

CYL 1 = 155

CYL 2 = 150

CYL 3 =168

CYL 4 =109

Notes About Cylinder 4: My rental compression tester had a short extension and was very hard to connect so I don't know if it had a great seal but let's assume it did.

This truck is my nephew's. Don't know much about its history before he asked for help. When I was removing the Spark Plugs, I noticed #4 plug did not seem torque down as tight the others like too easy to break away as removing. I think this one and possibly the second one had been installed cross threaded before. While installing #4 plug it had sort of a wiggle to it at first and as all of the plugs it seemed like it took more than normal turning of plugs before they bottomed out. I was able to torque them all at specs 14 -20 lbs.

I will check to see if #4 loosens up after it is able to idle. Any suggestions? Should I use some bolt tight or the like if it is an issue.

OBD2 Readings

Disconnected the MAF sensor and took some readings as it idled smoothly in Park but at about 1,500 - 1,600 RPMs and in drive it will idle about 938 RPMs smoothly - when I drive it it spits, jerks etc, at about 2,500 RPMs.

MAF Disconnected P0100 and check engine light on readings all under stopped conditions.

MIL Status ON = both in Park and Drive

Fuel Sys 1 = Closed then changes to open1 both in Park and Drive

Fuel Sys 2 = N/A both in Park and Drive

Cal Load % = 28.2 to 40.8 in Park and 42.0 in Drive

Coolant (F) = 185-189 in Park and 192-194 in Drive

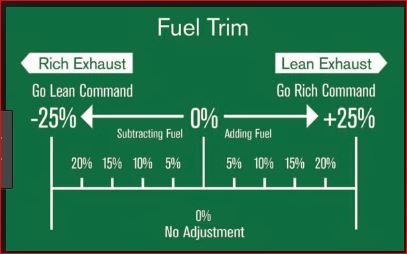

ST FTRM 1% = 1.6 to 25.0 (mostly 25.0) in Park and 0 to 5.5 in Drive

LT FTRM 1% = 0 in Park and -2.3 in Drive

MAP (HG) = 8.0-8.3 in Park and 12.4-13.0 in Drive

Engine Speed = 1513-1638 in Park and 938-983 in Drive

IGN ADV = 15.0-16.0 in Park and 10.0 in Drive

Veh Speed = 0 for both

IAT (F) = 129-142 in Park and 136-140 in Drive

MAF (LB/M) =.03 in both Park and Drive

ABSLT TPS % = 0 in both Park and Drive

O2S11 (V) =.72-.93 in Park and.77-.94 in Drive

ST FTRM 11% = -7.8 to -25.0 (mostly 25.0 in Park and -5.5 to.83 in Drive

O2S21 (V) =.87-.94 in Park and.04 I Drive

OBD2 Stat = CA for both - I guess this means it is a California Emissions type Vehicle

Sunday, May 22nd, 2022 AT 3:08 PM