Good morning,

I attached the procedure with some pictures below for you. Here are videos to help you make your own line or replace the brake flex hose.

https://youtu.be/sO43p4ZFUiM

and

https://youtu.be/1Prs_coIuCg

The process is the same in most cases.

Make sure you change the brake fluid while you are bleeding the system.

https://www.2carpros.com/articles/how-to-bleed-or-flush-a-car-brake-system

Roy

Brake Hose Replacement - Front (Single Piston Caliper)

Removal Procedure

1. Raise the vehicle. Refer to Vehicle Lifting.

2. Remove the front tires and wheels assembly.

3. Clean all dirt and foreign material from the brake hoses and the brake pipes.

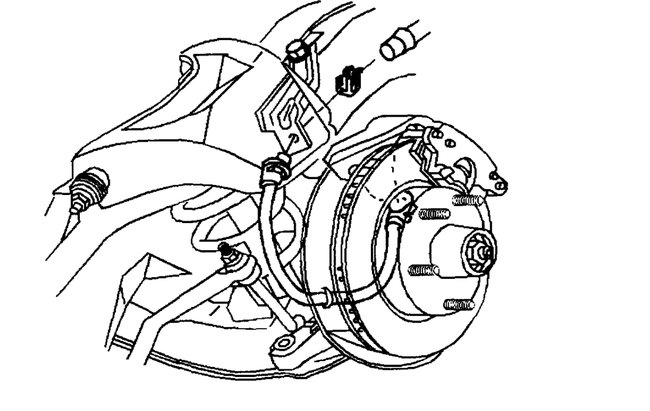

imageOpen In New TabZoom/Print

4. Using a backup wrench on the brake pipe fitting, disconnect the brake pipe from the brake hose.

Important: Install a plug or cap in the brake pipe to the exposed brake pipe fitting end in order to prevent fluid loss and contamination.

5. Disconnect the brake pipe fitting from the flex brake hose at the frame.

6. Remove the front brake hose retainer at the frame bracket.

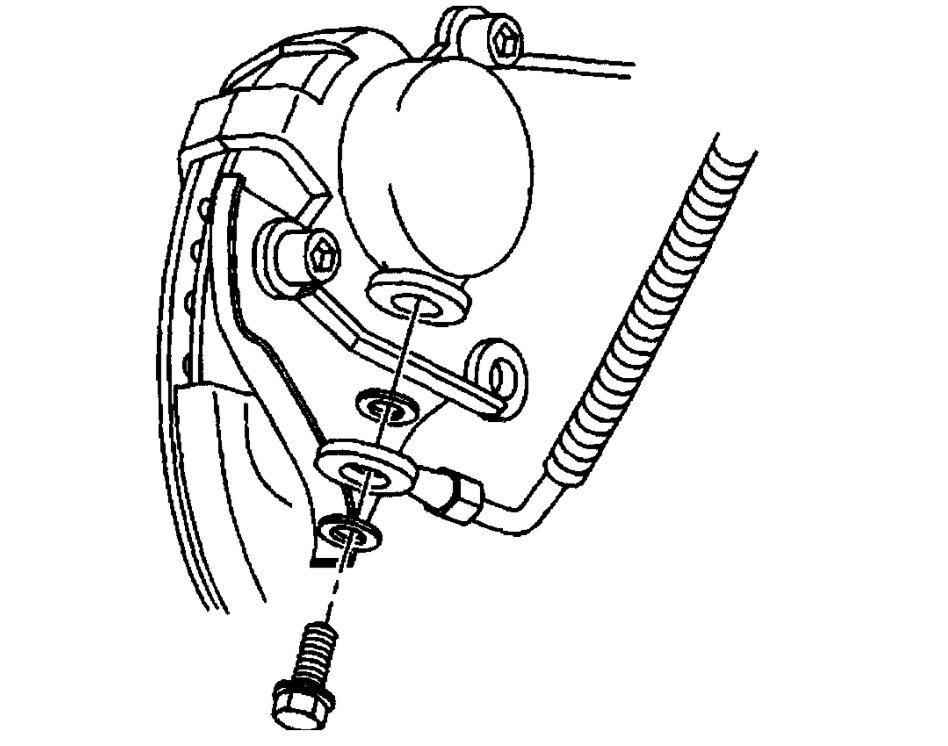

imageOpen In New TabZoom/Print

7. Remove the hose front flex brake hose bolt and gaskets from the brake caliper.

8. Remove the brake hose from the brake caliper.

9. Remove the copper gaskets from the brake hose bolt. These gaskets maybe stick to the brake caliper or the brake hose bolt.

Installation Procedure

Important: DO NOT reuse the old copper gaskets. Always use NEW copper gaskets.

1. Install the NEW copper gaskets on the brake hose bolt.

Notice: Refer to Fastener Notice in Service Precautions.

imageOpen In New TabZoom/Print

2. Install the brake caliper bolt to the brake caliper.

Tighten the brake hose bolt to 44 Nm (32 ft. lbs.).

imageOpen In New TabZoom/Print

3. Remove the plug or cap from the exposed brake pipe fitting.

4. Install the brake hose to the brake pipe.

Important: Ensure that the brake hose is not twisted and does not come in contact with any of the suspension components.

5. Using a backup wrench on the brake pipe fitting, tighten the brake hose fitting.

Tighten the brake hose fitting to 17 Nm (13 ft. lbs.).

6. Install the brake pipe retaining clips.

7. Bleed the hydraulic brake system.

8. Install the tire and wheel assembly.

9. Lower the vehicle. Refer to Vehicle Lifting.

Images (Click to make bigger)

Wednesday, March 17th, 2021 AT 5:57 AM