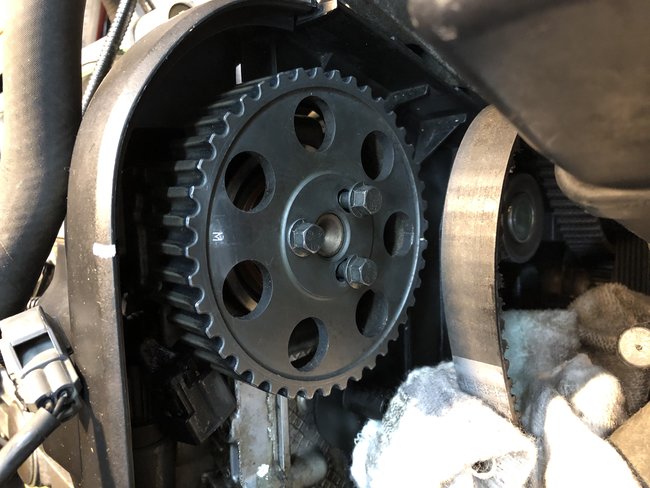

The picture of the cams with the pointers indicating cam sprocket position was taken with the crankshaft marks lined up. I'll go ahead and repeat the cam/crank alignment procedure.

Let's restate what I need to do to get the timing dialed in.

To achieve the correct timing on this engine, all I need to do is (omitting mention of removing non-relevant engine parts):

1. Remove timing belt.

3. Align the crankshaft sprocket mark with the raised metal alignment mark on the oil pump

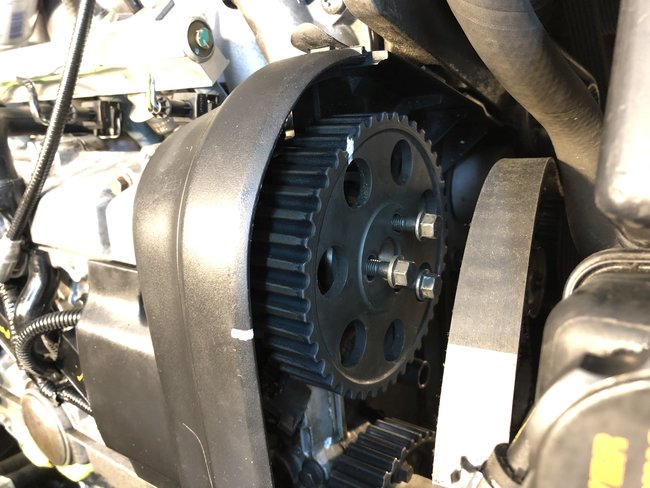

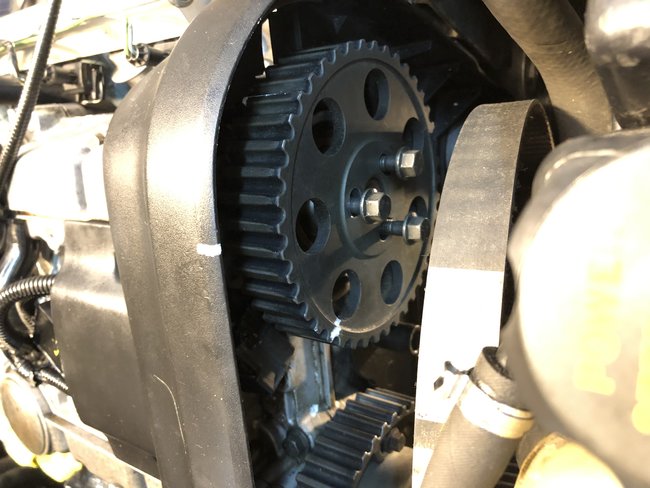

4. Rotate cams to match marks on cams to timing cover marks.

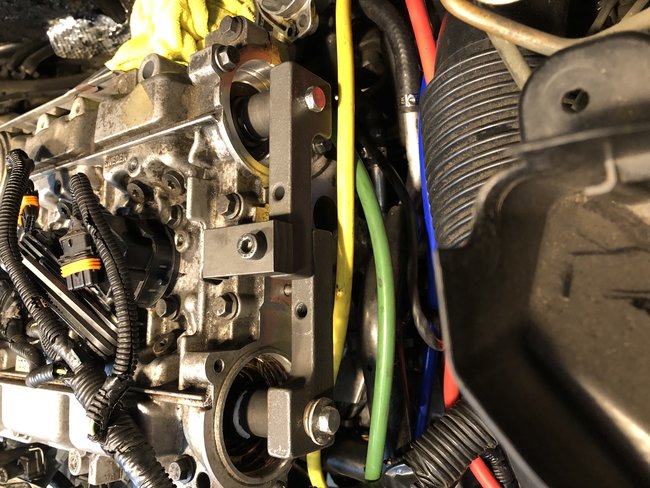

5. Lock cams in position. When the timing marks are on, the slots in the ends of the cams where the cam lock tool goes are slightly out of horizontal. The cam lock tool is made to lock the cams in a horizontal position, so the cams have to be turned slightly to horizontal, which throws the timing marks off a bit. I have to assume that this has no effect on actual engine performance.

6. Turn vvt hub clockwise, feeling spring tension, about an inch or so, until it stops. Find a way to lock it in that position.

7. Install timing belt, making sure that the vvt hub stays locked and spring-loaded.

8. Unlock the cams.

9. Turn the crankshaft slowly by hand 4-5 complete revolutions (or more if that's what you think you need to do) to confirm smooth operation. If there is resistance, stop and go back to step #1.

Please let me know if this is right or wrong. I thought this is what I did the last time, but the cam misalignment picture tells a different story. I'm heading out now to get the car prepped for the do-over. I'll check back before I get to the re-set point to look for a response.

I checked the connections on the injectors before I started the engine. The #2 connector did feel a little loose, so I unsnapped it and put it back on. It seems to have helped, but I can't be 100% sure because the timing issue sort of dominates right now.

I do appreciate the time you're investing in helping me get my baby back on the road. -Rick

Friday, September 20th, 2019 AT 12:53 PM