Good afternoon,

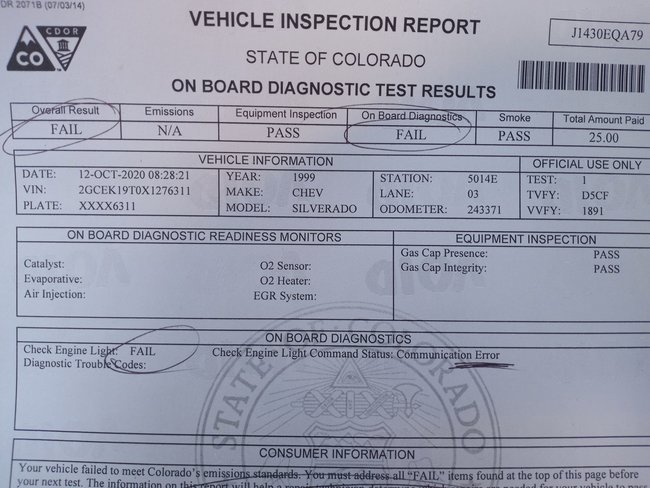

Something I saw in the report is a clue.

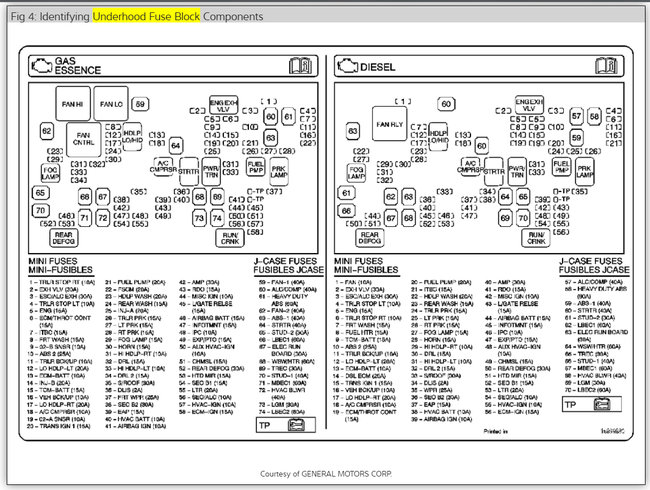

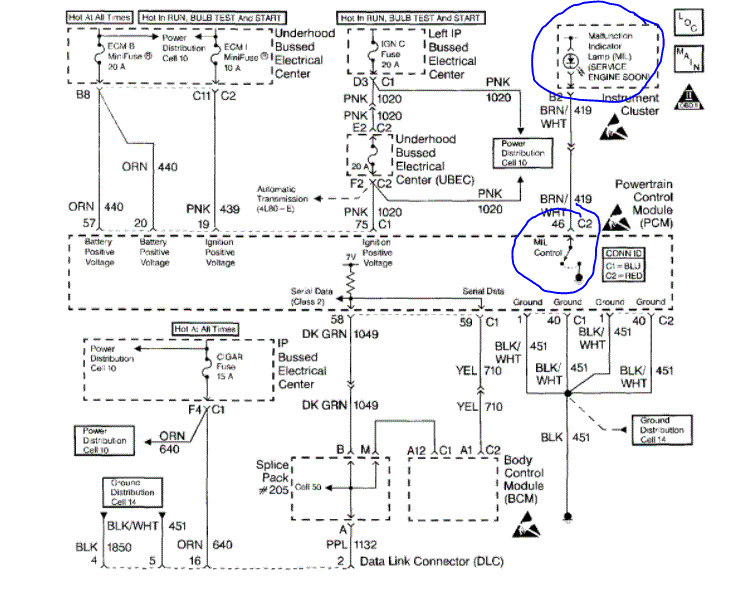

The check engine light apparently does not work as well as no communication. With those 2 issues present that means either there is no power to the ECM or the ECM itself is no good.

https://www.2carpros.com/articles/checking-a-service-engine-soon-or-check-engine-light-on-or-flashing

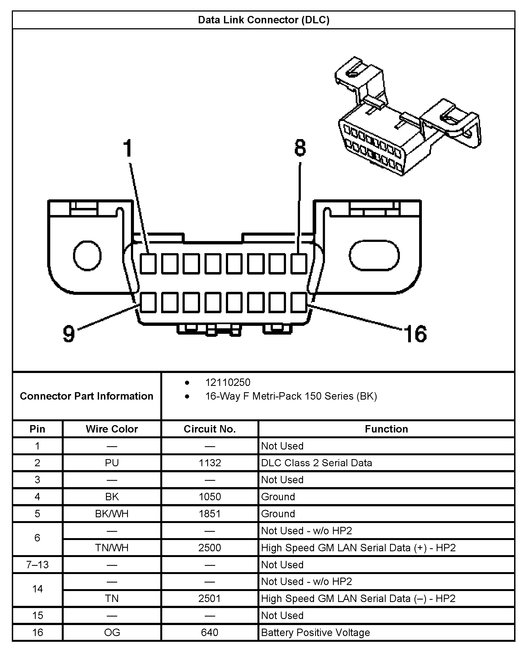

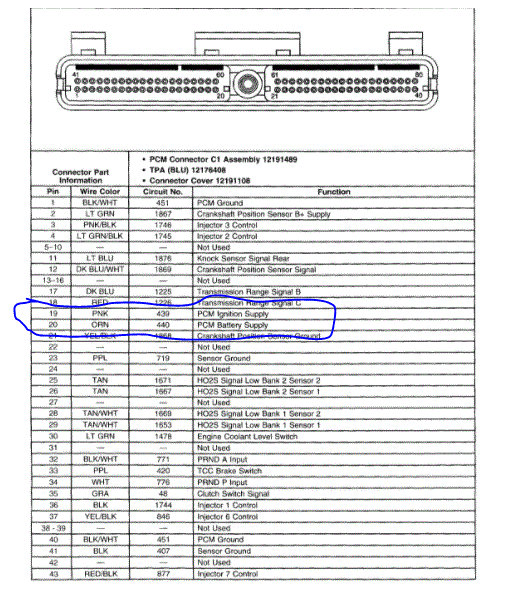

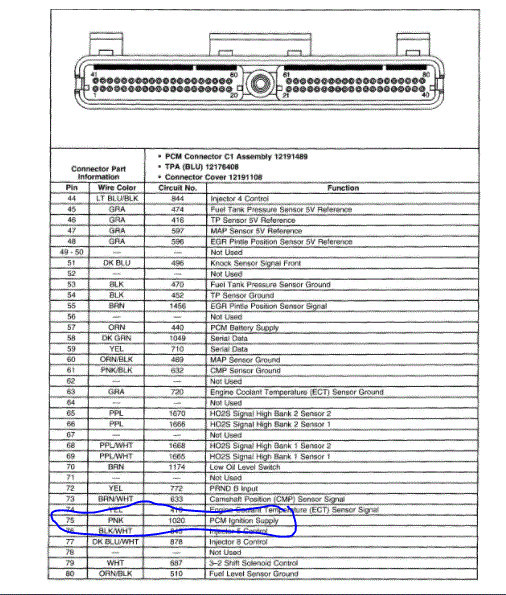

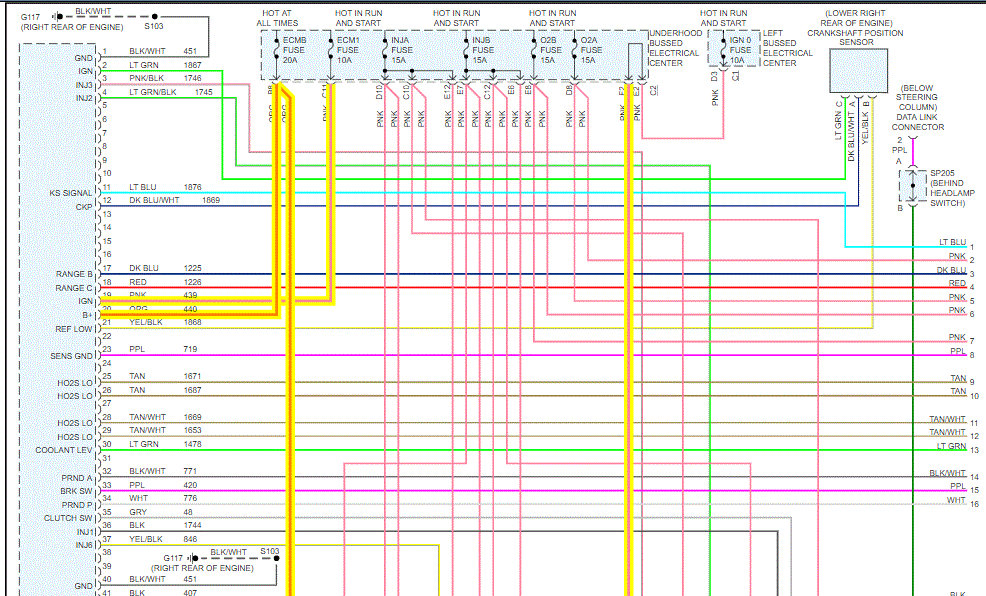

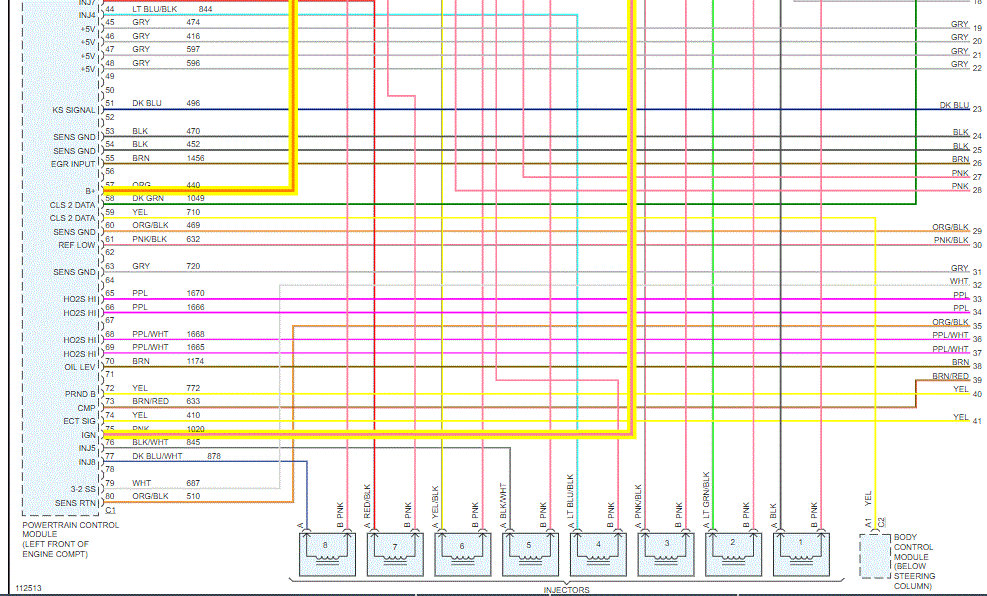

I attached a connector diagram of the ECM. I circled the pins that need to have voltage with the key on. Verify this voltage to those pins.

https://www.2carpros.com/articles/how-to-check-wiring

Roy

Circuit Description

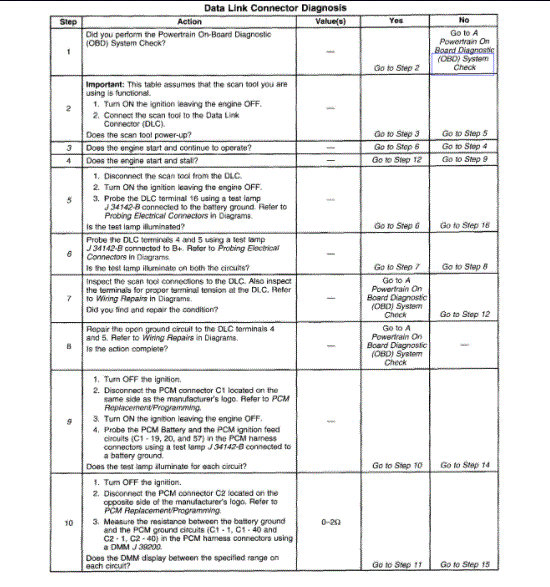

Use a properly functioning scan tool with the diagnostic tables. DO NOT use the Clear Info function unless instructed by a diagnostic procedure.

Important: This vehicle, equipped with a Powertrain Control Module (PCM), utilizes an Electrically Erasable Programmable Read Only Memory (EEPROM). Program the new PCM when the diagnostics call for replacement of the PCM. When the PCM or BCM is replaced the PCM Password Learn procedure must be performed. Refer to DTC P1631 Theft Deterrent Password Incorrect. See: A L L Diagnostic Trouble Codes ( DTC ) > P Code Charts P1631

Test Description

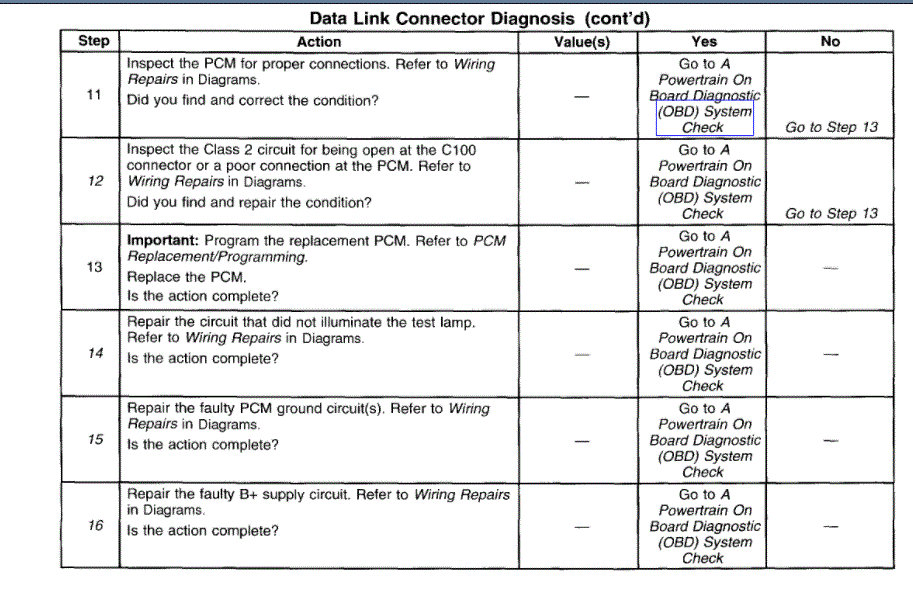

The numbers below refer to the step numbers on the diagnostic table.

3. An engine that just cranks and does not attempt to start indicates that the PCM is not powered-up.

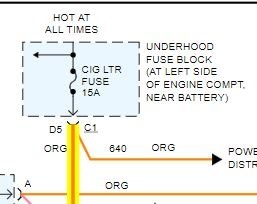

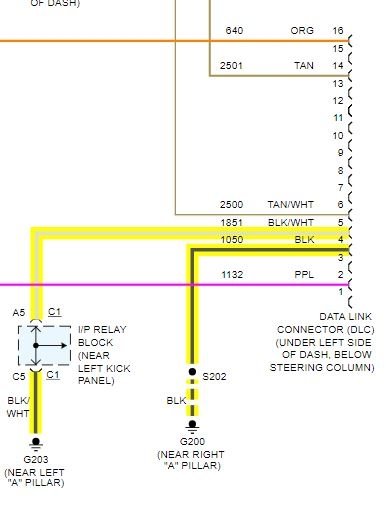

5. This step is checking for a B+ supply to the Data Link Connector (DLC).

6. A ground must be available at both terminals for the scan tool to function properly.

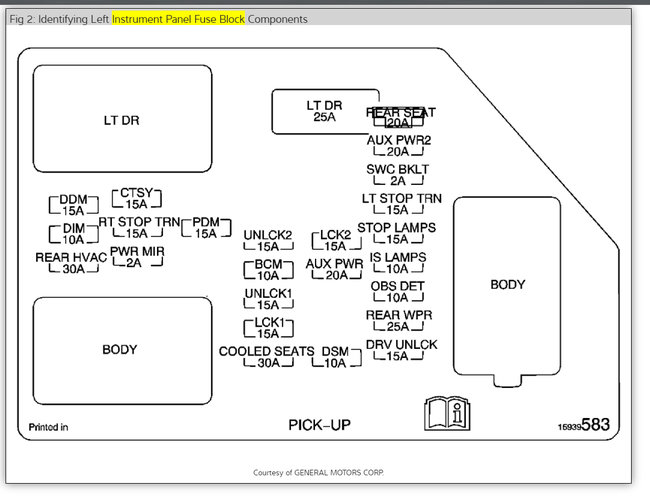

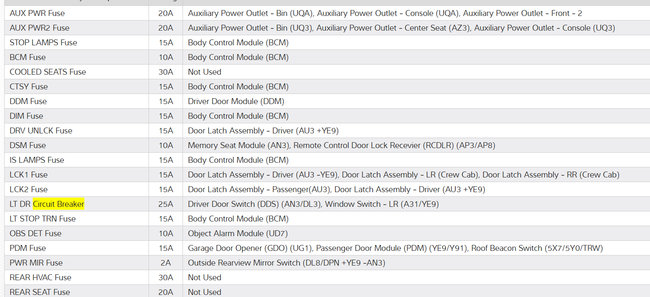

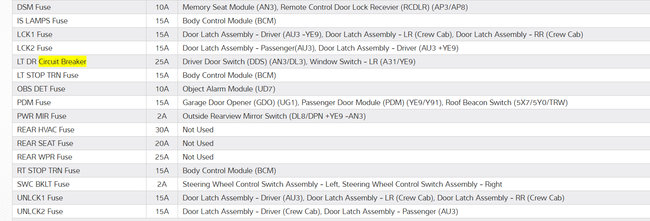

9. A no start condition occurs when the fuse(s) for the battery or ignition feed circuits is open. The MIL is inoperative when the battery and ignition feed circuit fuses open. Inspect the circuits for being grounded when either of these fuses open.

12. The scan tool does not communicate when the C100 connector is open. The C100 connector is located under the under hood electrical center.

14. If the test lamp does not illuminate for a circuit, inspect the fuse for being open. If the fuse is open, inspect the circuit for a short to ground.

15. Inspect for an open ground circuit. Inspect G103 located on the right rear of the engine block for an open or for a poor connection.

16. Inspect for an open fuse that supplies the DLC. If the fuse is open, repair the grounded circuit.

ECM

Service of the PCM should normally consist of either replacement of the PCM or EEPROM programming. If the diagnostic procedures call for the PCM to be replaced, the PCM should be checked first to see if it is the correct part. If it is, remove the faulty PCM and install the new service PCM.

THE SERVICE PCM EEPROM WILL NOT BE PROGRAMMED. DTC P0601 and P0602 indicates the EEPROM is not programmed or has malfunctioned.

IMPORTANT: The following must be performed anytime the PCM is replaced:

1. Programming of the EEPROM

2. The PCM Password learn procedure. Refer to DTC P1631 Theft Deterrent Password Incorrect.

3. The Idle Learn Procedure. Refer to PCM Idle Learn Procedure.

4. The CKP System Variation Learn Procedure. Refer to CKP System Variation Learn Procedure.

5. Reset the Engine Oil Life monitor. Refer to Engine Oil Life Monitor Reset Procedure.

6. The Functional Check

The following must be performed anytime the PCM is disconnected, loses power, or is reprogrammed.

1. The Idle Learn Procedure. Refer to PCM Idle Learn Procedure.

2. The Functional Check

IMPORTANT: To prevent internal PCM damage, the ignition must be OFF when disconnecting or reconnecting power to the PCM (for example, battery cable, PCM pigtail, PCM fuse, jumper cables, etc.).

imageOpen In New TabZoom/Print

REMOVAL PROCEDURE

IMPORTANT: Remove any debris from the PCM connector surfaces before servicing the PCM. Inspect the PCM module connector gaskets when diagnosing/replacing the PCM. Ensure that the gaskets are installed correctly. The gaskets prevent contaminate intrusion into the PCM.

1. Release the PCM cover mounting holes (1, 5) away from the mounting tabs on the PCM mounting bracket.

2. Release the PCM cover (8) from the mounting bracket.

3. Remove the PCM cover.

NOTE: Do not touch the connector pins or soldered components on the circuit board in order to prevent possible electrostatic discharge (ESD) damage to the PCM.

NOTE: In order to prevent internal damage to the PCM, the ignition must be OFF when disconnecting or reconnecting the PCM connector.

4. Disconnect the PCM harness connectors (6).

5. Release the spring latch (2) from the PCM.

6. Release the PCM mounting tabs (3) from the PCM.

7. Remove the PCM (4) from the engine compartment.

INSTALLATION PROCEDURE

NOTE: Do not touch the connector pins or soldered components on the circuit board in order to prevent possible electrostatic discharge (ESD) damage to the PCM.

NOTE: In order to prevent internal damage to the PCM, the ignition must be OFF when disconnecting or reconnecting the PCM connector.

1. Install the PCM (4) to the PCM mounting bracket (7) ensuring that the mounting tabs are engaged.

2. Secure the spring latch (2) to the PCM.

3. Connect the PCM connectors (6) to the PCM (4).

Tighten

Tighten the PCM connector end fasteners to 8 N.m (70 lb in).

4. Install the PCM cover (8) to the PCM mounting bracket (7), ensuring the mounting tabs on the PCM mounting bracket are engaged into the mounting holes in the PCM cover.

5. If a new PCM is being installed, program the EEPROM.

PCM Programming

1. Setup - Ensure that the following conditions have been met:

The battery is fully charged.

The ignition is ON.

2. Program the PCM using the tatest software matching the vehicle. Refer to Techline terminal/equipment users instructions.

3. If the PCM fails to program, proceed as follows:

Ensure that all PCM connections are Ok.

Check the Techline terminal/equipment for the latest software version.

Attempt to program the PCM. If the PCM still cannot be programmed properly, replace the PCM. The replacement PCM must be programmed.

4. Perform the PCM Password learn procedure. Refer to DTC P1631 Theft Deterrent Password Incorrect

5. Perform the Idle Learn Procedure. Refer to PCM Idle Learn Procedure.

6. Perform the CKP System Variation Learn Procedure. Refer to CKP System Variation Learn Procedure.

7. Reset the Engine Oil Life monitor. Refer to Engine Oil Life Monitor Reset Procedure.

8. The Functional Check

Functional Check

1. Clear the Diagnostic Trouble Codes (DTCs).

2. Perform the On-Board Diagnostic System Check.

3. Start the engine and idle for one minute.

4. Use the scan tool in order to check for DTCs.

Images (Click to make bigger)

Wednesday, May 5th, 2021 AT 1:58 PM

(Merged)