Would you like to know how your vehicle’s air conditioner works? The system looks complicated, but it's really quite simple. Once you know how it delivers cold air you will be better informed when problems occur and how to fix them.

What Does It Do?

Not only does the air conditioner cool the passenger compartment, it operates when the defroster is on as well. This seems strange but, many manufactures run the AC system in the defroster mode. The reason for this is to remove moisture while keeping the windshield dry from humidity. Sometimes you will notice plain water leaking from under the passengers side of the car about where the passenger foot well would be, this is normal and is the result of moisture build up on the evaporator core which you will learn about further down in this guide.

When the air condition system is on it will reduce the car's MPG slightly, it will also cause the engine to run warmer, this is why the radiator cooling fans operate while passing air over the AC condenser.

How Does It Work?

When you give the command to have the air conditioner come on, the blower motor will start to run at the desired speed while energizing the compressor of the system. The HVAC system blend door actuators will then adjust the vent air flow to allow the air through the evaporator. This is where the coolness is generated and then pushed through the dashboard vents.

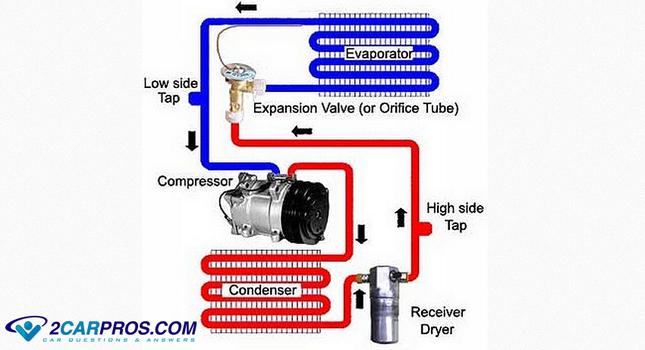

Here is a short description of the air conditioner system components and what the do:

- Compressor: Acts as the pump which circulates the refrigerant.

- Condenser: Located in front of the engine radiator and cools the refrigerant into a liquid state.

- Receiver Dryer: Removes moisture from inside the system to prevent rust and corrosion.

- Expansion Valve/Orifice Tube: Releases high pressure refrigerant gas into the evaporator. (Each part does basically the same thing, though an expansion valve can vary the amount of refrigerant passed through it to help control temperature.)

- Evaporator: Accepts low pressure refrigerant which is cool and allows the blower motor to pass air through it.

- High Side Service Port: This is where a pressure gauge set is attached and monitored.

- Low Side Service Port: Where the refrigerant is added while the system is running and the pressure monitored.

- High Pressure Hose: This hose and fittings transfer refrigerant from the compressor to the condenser, and then to the receiver dryer, then onto the expansion valve/orifice tube.

- Low Pressure Hose: Transfers the expelled refrigerant from the evaporator to the compressor.

- High and Low Side Pressure Sensors: Used to monitor the system for safety and performance controls.

Here is an image of the closed system for visual clarification:

Refrigerant

This is where the magic happens, in 1928, Thomas Midgley, Jr. aided by Charles Franklin Kettering discovered refrigerant and its amazing properties, once pressurized and released a coldness was experienced. The air conditioner system was invented by the four Goldberg brothers, Lowell, Norman, Hiram, and Max, developed on July 17, 1946.

Commonly known as "Freon" which was a popular brand name, is part fluid, part gas, which is held under pressure inside the AC system. When the system is not running the refrigerant remains a gas under low pressure, about 70 psi. When the system is activated (switched on) the compressor will bring the high side to about 235 PSI where it is pushed through an expansion valve or orifice tube, causing the low side pressure to drop to about 45 PSI inside the evaporator.

The entire action is basically a high pressure liquid, then released into a low pressure gas. If you take a can of hair spray and then release the product (hair stiffener), along with the propellant, the spray-can will get the cold. The exact same chemical reaction used by the air conditioner, the only exception is the gas is recovered inside the evaporator and then recycled into the system. The refrigerant is transferred from one component to another by using hoses or tubes.

Air Conditioner Components Explained

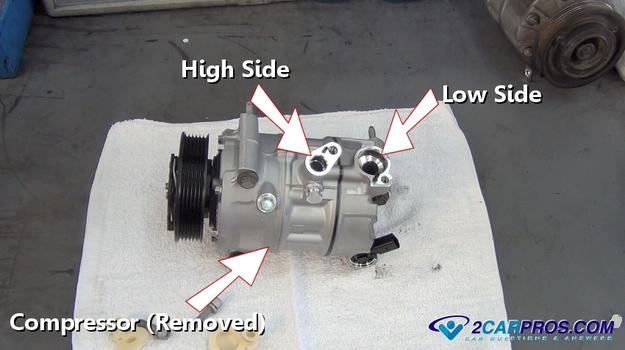

1. Compressor: This is what a typical compressor looks like, it features the high and low side ports, a clutch, which is activates the compressor when 12 volts is sent turning the system on, and a belt pulley which freewheels when the system is not in use. The compressor is the main mechanical part of the system with internal workings that must be lubricated by PAG oil (synthetic).

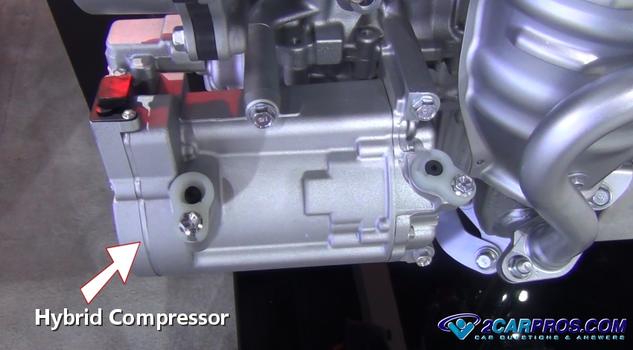

On hybrid engines or electric vehicles the compressor is electrically powered by the vehicle's battery pack. A small electric motor is fitted inside of the compressor which pressurizes the refrigerant. These compressors have a pair of large gauge wires from the compressor controller.

2. Condenser: Located in front of the engine radiator, it cools the refrigerant from the compressor by using engine cooling fan before it heads into the evaporator. Some condensers are designed with a receiver dryer attached which acts as a refrigerant cleaner and moisture remover, this helps the system last longer. Some systems will have an accumulator that does the same job but is located closer to the evaporator.

3. Evaporator: Located inside the HVAC plenum and is where the high pressure refrigerant is released to create the cold air. The blower motor forces air through the core and out through the air vents.

4. Hose or Tubes: Used to transfer the refrigerant from and to various components.

5. Service Ports: High and low side service ports are used to add Freon and vacuum down and recharge and the system. These ports are usually located on each hose but can be on the compressor or accumulator as well.

Watch the Video!

Please watch this video of the air conditioner system being explained to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.