The ECT, MAP, IAT, and TPS all share a common 5.0-vot supply from the Engine Computer, however, part of the ECT's circuit is inside the computer, so there is no 5.0-volt wire at that sensor. All of these sensors also share a common ground wire, but it goes through the computer first so it can be monitored, then it goes to ground. You'll typically find 0.2 volts on that ground wire. This is the only circuit that can be connected with that added-on wire you found. Your scanner is showing 195 degrees for the ECT, so that sensor is working correctly and has to be wired correctly.

As for "key-on / engine-on or off, the scanner will tell you when it is unhappy. To do the engine speed function, the engine has to be running. I'm not aware of any test that lets you run the idle speed motor with the engine off. Most scanners require the engine to be not running to erase diagnostic fault codes, but I was just helping my friend at his body shop, and on a 2019 Chevy Equinox, the codes could only be erased with the engine running. That was a first for us, and we were surprised to find that.

My scanners will read road speed and the state of each cruise control switch any time, but it will not allow the servo's solenoids to be activated unless the engine is not running. That avoids activating the "vacuum" solenoid while you're driving. To do so could mean they find you in the next county going 120 mph!

Sensor data, switch state, (on or off), and output condition, meaning is a relay or solenoid being turned on, can all be viewed regardless if the engine is running or not. In addition, some scanners for some car models will generate a screen list of data specifically related to a crank / no-start condition. To avoid confusion, my DRB3 lists switches as "pressed" or "released" rather than "on" or "off". A brake light switch and a door switch are off when they're pressed. A horn switch is on when it's pressed.

For the engine speed test, mine doesn't allow me to select a speed lower than normal idle speed. As I recall, it starts out with the first choice being 1,000 rpm, then I can only select an up or down arrow to go to 1,200, 1,400, 1,600, 1,800, and 2,000. From there I have to use the down arrow or select, "stop" to exit the test and bring it back down to normal idle speed. Any defect, a vacuum leak, for example, that results in a high idle speed will over-ride what the computer is trying to do during the engine speed test. If the scanner is telling the computer to run the engine at 1,400 rpm, for example, it can't do that if something else is already making engine speed 1,500.

The Engine Computer looks at a lot of sensor data and operating conditions to calculate the desired idle speed and ignition timing. It is very unlikely to calculate the wrong speed. There are four driver circuits inside the computer that operate the idle speed motor. Together they cause a slowly-rotating magnetic field inside that motor that the armature follows. As the armature rotates, it is on a threaded shaft that retracts or extends the pintle valve. If any one of those driver circuits were to develop a shorted driver transistor, or some other defect, that magnetic field inside the idle speed motor would no longer rotate. Some of the coils would pulse, but at most, the armature would just twitch back and forth. Engine speed would not adjust by the computer. If you were to remove the idle speed motor and forcibly push the valve in, then install it that way, idle speed would be way too high, the computer would try to bring it down, but actual engine speed wouldn't change. A quick way to see if the computer is working is to do anything that lowers engine speed, then see if the computer can bring it back up. I saw a horrendous example of this at a Chrysler training class some years ago. With a V-8 Jeep engine, the instructor unplugged one fuel injector. Almost immediately, the idle steps went from 32 to 50, and idle speed stayed right were it was supposed to be. By the end of the demonstration, he had six of the eight injectors unplugged, and idle speed was still correct. Obviously the engine was running very poorly, but his comment was, "this shows how much control the computer has over engine speed".

If you had a problem with the computer or the idle speed motor and circuit, engine speed would drop if an injector was unplugged or you had a spark-related misfire. You can also introduce an artificial vacuum leak that causes idle speed to be too high, then watch the steps, or "counts" to see if they come down. If you see the counts at around five to ten, the computer is trying to lower engine speed, but without success. "Without success" means whatever is causing the high idle speed is beyond the computer's control. It does have control of the desired (variable) vacuum leak which is the air passage the idle speed motor sits in, but it doesn't have control of a vacuum hose you pulled off, of some other vacuum leak.

Another way to verify the idle speed system is working is to remove the idle speed motor but keep it plugged in, then watch the valve when you turn the ignition switch on and off. At some point the valve will extend fully, then retract a small amount. That could occur when you turn the ignition switch on, but I see it more when the switch is turned off. By fully extending the valve more counts than necessary, the computer is sure it is extended as far as possible, so it is confident it knows where it is. It is "in sync" now in case it moved out-of-sync a few counts during the last drive cycle. Now the computer retracts the valve a predetermined amount to provide that idle flare-up to 1,500 rpm at the next engine start-up.

Your scanner can't bypass the Engine Computer. When working with the Engine Computer, there are basically only four wires in use in the scanner's cable. Those are the ground, the 12-volt feed, and two "data buss" wires. The Engine Computer, Transmission Computer, instrument cluster, Body Computer, Anti-Lock Brake Computer, and Air Bag Computer all need to know road speed, but there are not speed sensors for each one of them. Multiple computers need to know coolant temperature because they modify how they send commands based on engine temperature, but there's only one coolant temperature sensor, not one for each computer. Instead, each computer takes a turn at sending its data out onto the data buss to every other computer. It's up to those other computers whether they want to look at the data they're receiving. For a fraction of a second, the Engine Computer will transmit engine speed, temperature, load, intake air temperature, whether or not the charcoal canister's purge valve is activated, and the AC compressor relay is turned on.

At this time, the Transmission Computer looks at that data, and modifies its shift schedules according to coolant temperature, engine speed, engine load, and throttle position. It sees but ignores things like the charcoal canister's purge valve. Eventually the Transmission Computer gets a turn at transmitting data onto the data buss. Among other things, it transmits road speed. Now the Body Computer can see that and turn on speed-sensitive door locks. The radio is also connected to the data buss. It can raise the volume above a certain speed to overcome road noise.

The scanner is just one more computer connected to the data buss. (By the way, a '99 Cadillac could have up to 47 computer modules on the data buss). That means anything the scanner displays had to come through those two wires, and anything you ask the computer to do also goes through those two wires. Nothing can be activated by you without the commands going through one of the computers. You're telling the scanner to talk to the computer, then the computer responds by doing what you asked it to do.

When you run into a data buss, you can identify them by observing the pair of wires are twisted around each other. We used to do the same thing with the older flat "twin lead" for tv antennas. Any stray magnetic field will induce a voltage into a wire it crosses. By twisting the pair of wires, those voltages are induced equally in both wires, so the difference is "0", and they cancel each other out. This becomes a bigger problem because the signal voltages on the data buss wires is so small. They start out with 6.0 volts on each one, then, when a digital pulse comes along, those voltages rise by 0.2 volts on one wire, and fall by 0.2 volts on the other one. In a harness with lots of wires, there's pulses from firing the ignition coils and injectors, along with other switched circuits. Being fairly high-current circuits, they generate large magnetic fields which induce large voltage spikes into adjacent wires. That doesn't bother lighting or most other circuits, but it can seriously affect sensor signal circuits and those on the data buss.

In later years there are multiple data busses on most cars. Some are high-speed circuits that are needed to process signals immediately. One of those is for the Engine Computer so it can modify fuel metering and ignition timing calculations quickly for best performance and lowest emissions. The Air Bag also uses a high-speed data buss so it can pop the air bag at the exact instant it needs to. A low-speed data buss is used for less critical systems such as for lights, horn, and gauges. It doesn't matter if those take a few extra milliseconds to do their thing.

I have to say this next comment carefully, but at least with Chrysler products, there is nothing you can do, short of outright sabotage, to damage an Engine Computer. If you ground the 5.0-volt sensor supply to short it to ground, the computer will turn it off to protect it. Once that short is removed, you simply turn the ignition switch off, then back on to reset the supply. If sensor signal wires are grounded or shorted to 5.0 volt or even 12 volts, the computer will detect that and set the appropriate fault codes. Those incorrect voltages don't do any damage. Anything with a coil of wire will generate a reverse voltage spike of up to 300 volts when current through it is turned off. Relays have damping diodes built in to short out those spikes, and the computer has damping diodes for the switching circuits for the injectors, ignition coils, and solenoids it operates. If you look at the wiring diagrams, you'll see a lot of switching done by the computer is done on the ground side of relays and solenoids. That makes any voltage spikes appear on the 12-volt side where they are easily damped and absorbed by the battery.

GM and Chrysler do things very much the same way, but during the '80s and '90s, Engine Computer failures on Chrysler products were extremely rare. GM, on the other hand had a real lot of failures in the early '90s, but those were not caused by external defects in the cars. If a replacement computer was needed, and that replacement also had a problem, chances are that replacement was a used one from a salvage yard. By '98, GM didn't have any more computer trouble than any other manufacturer.

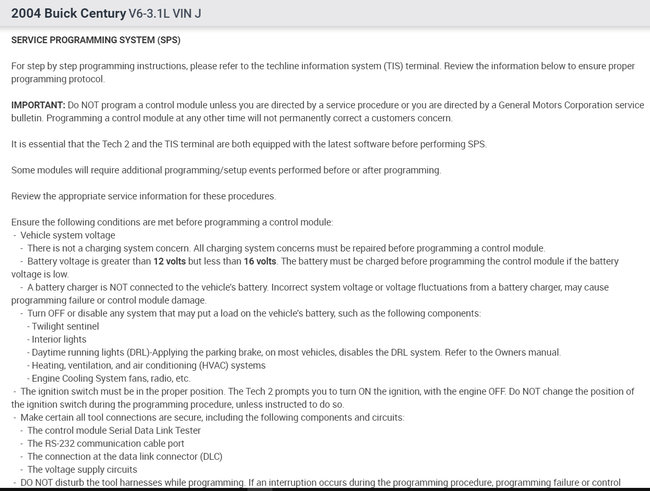

GM and Chrysler use the same idle speed motor, but while Chrysler's range goes from "0" to "256", I don't know if GM uses the same scale. If they do, your screen is showing 190 steps, which is way too high. I don't think that 8-cylinder Jeep running on only two cylinders reached that high of a step. Remember, if something such as a vacuum leak was causing your idle speed to be too high, the counts would be real low, indicating the computer was closing the idle speed motor's valve to reduce air flow. It's not doing that. Yours is showing the computer is requesting that high idle speed. That has to be in response to a sensor value or something it is seeing. Of notable interest is "engine load" of 21 percent. I don't recall seeing that on my vehicles, but it seems too high for a vehicle idling in "park". I also question the TPS voltage. I'm used to seeing around 0.6 to maybe 0.7 volts at closed throttle. Remember my story of the TPS that latched in various positions? With the engine running, the only fairly constant symptom was idle speed just high enough to get my attention, ... Perhaps 1,000 rpm. That's when I noticed the TPS was at around 2.6 volts, or incorrectly telling the computer "half throttle".

From what I've read so far, I think your observation of the TPS voltage varying at closed throttle is the thing to pursue. A comment I post quite often is, "when a part is referenced in a fault code, it is actually the cause of that code only about half of the time. The other half are caused by wiring and connector terminal problems, or mechanical problems associated with that part". The same holds true when there's no fault code being set but the signal voltages are wrong. The TPS is strictly a mechanical sensor with no touchy electronics inside. As such, it is fairly immune from sending a wrong voltage compared to electronic sensors like the MAP and MAF. Even if a tiny chip of carbon were to break off from the resistor element and get caught under the movable contact, you still wouldn't see the TPS signal voltage change when the throttle was being held steady. What is much more likely to change on its own is wiring, particularly connector terminals. What is your understanding of electrical theory? If there is some corrosion between the pair of mating connector terminals for the ground circuit, the signal voltage would go high intermittently. Likewise, if there was some corrosion on the terminals for the 5.0-volt supply, the signal voltage would drop intermittently. Remember too both the 5.0-volt supply and the ground wires feed multiple sensors, so there's going to be splices, and those are dandy places to find corrosion and bad connections.

Were I think I would start is by monitoring the TPS signal voltage with the engine off, and the throttle propped open half way. That will make any tiny glitch caused by the ground circuit to be more easily noticeable. Use a separate digital voltmeter for this. Now wiggle the harnesses and plugs. The signal voltage should hold rock solid. I could see it bouncing around a couple hundredths of a volt due to stray magnetic fields or other circuits in the car turning on or off, but if you see it change even a tenth of a volt, I'd look at what I was doing that caused that to happen. Watch the readings on the scanner at the same time. If those readings change while those on the voltmeter don't, suspect a problem in the signal wire.

Also look at all the other sensor voltages to see if something doesn't look right. You're showing 95 degrees for intake air temperature. Is it really that hot, or could that be from engine heat migrating up to the IAT while the engine isn't running?

Monday, October 12th, 2020 AT 8:00 PM