Hi,

Listening to how it is revving up and down, the first thing I suspect is a faulty idle air control valve (IAC). The IAC is what is responsible for maintaining idle speed.

Here are the directions for replacement. However, before getting a new one, remove the old one and make sure there isn't a carbon build up in the throttle body and on the pintle. Also, if you have someone turn the key from off to on, you should see the pintle move.

___________________________________

1997 Chevy Truck K Tahoe 4WD V8-5.7L VIN R

Idle Air Control (IAC) Valve Replacement

Vehicle Powertrain Management Fuel Delivery and Air Induction Idle Speed/Throttle Actuator - Electronic Service and Repair Procedures Idle Air Control (IAC) Valve Replacement

IDLE AIR CONTROL (IAC) VALVE REPLACEMENT

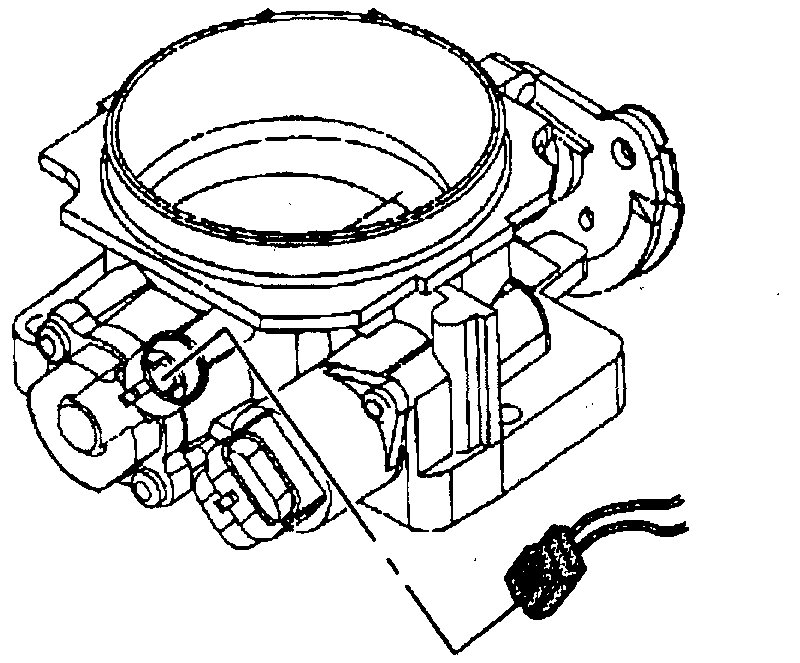

Throttle Position Sensor Electrical Connector

pic 1

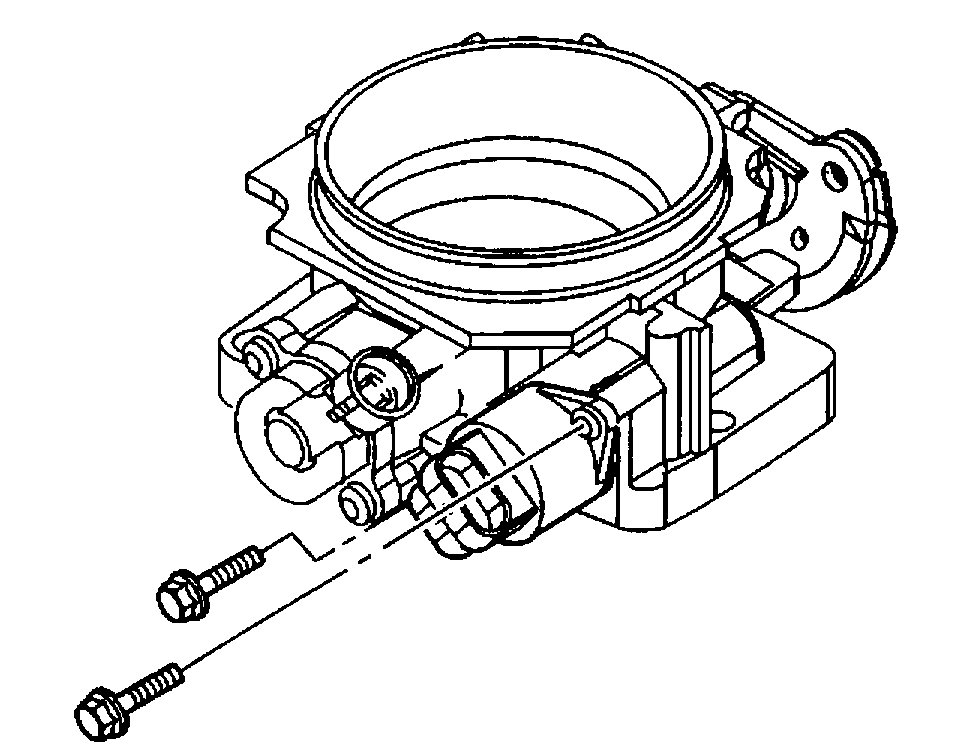

pic 2

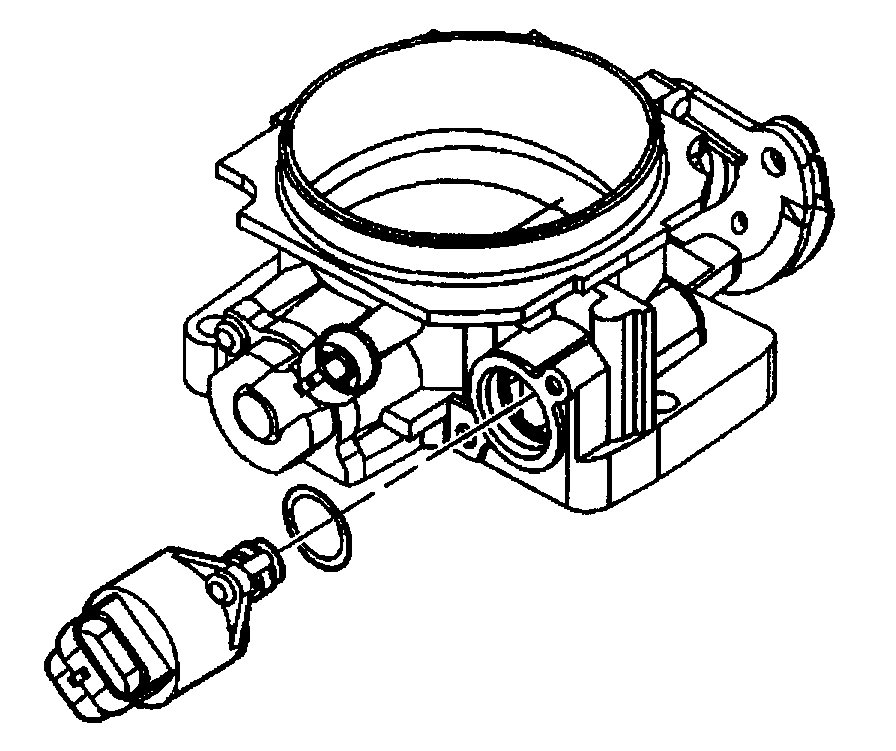

pic 3

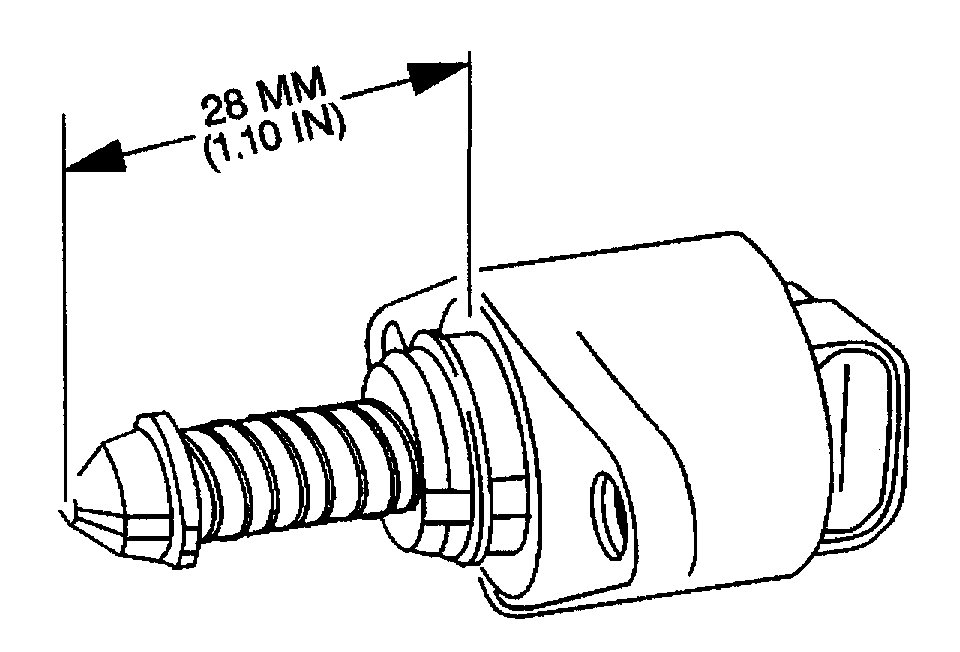

pic 4

REMOVAL PROCEDURE

1. Remove the electrical connector from the Idle Air Control (IAC) valve

2. Remove the IAC valve attaching screws.

CAUTION: If the IAC valve has been in service: DO NOT push or pull on the IAC valve pintle. The force required to move the pintle may damage the threads on the worm drive. Also, DO NOT soak the IAC valve in any liquid cleaner or solvent, as damage may result.

3. Remove the IAC valve assembly.

4. Remove the O-ring.

CLEANING AND INSPECTION PROCEDURE

1. Clean the IAC valve O-ring sealing surface, pintle valve seat, and air passage.

Use the carburetor cleaner and a parts cleaning brush in order to remove carbon deposits. Follow instructions on the container.

Do not use a cleaner that contains methyl ethyl ketone, an extremely strong solvent and not necessary for this type of deposit.

Shiny spots on the pintle or seat are normal. They do not indicate misalignment or a bent pintle shaft.

If air passage has heavy deposits, remove the throttle body for complete cleaning.

2. Inspect the IAC valve O-ring for cuts, cracks, or distortion. Replace if damaged.

NOTE: If installing a new IAC valve, replace with an identical part. The IAC valve pintle shape and diameter are designed for the specific application.

3. Measure the distance A between tip of IAC valve pintle and mounting flange. If greater than 28 mm, use finger pressure in order to slowly retract the pintle. The force required to retract the pintle of a new valve will not cause damage to the valve.

MEASUREMENT PROCEDURE

NOTE: If installing a new IAC valve, replace with an identical part. The AC valve pintle shape and diameter are designed for the specific application.

Measure the distance A between tip of IAC valve pintle and mounting flange. If greater than 28 mm, use finger pressure in order to slowly retract the pintle. The force required to retract the pintle of a new valve will not cause damage to the valve.

INSTALLATION PROCEDURE

2. Lubricate the IAC valve O-ring with clean engine oil.

2. Install the IAC valve assembly.

3. Install the attaching screws.

Tighten

Tighten the IAC valve attaching screws to 3.0 Nm (26 lb. In.).

4. Install the electrical connector.

5. Reset the IAC valve pintle position.

5.1. Turn the ignition switch to the ON position for 5 seconds.

5.2. Turn the ignition switch to the OFF position for 10 seconds.

5.3. Start the engine.

5.4. Check for the proper idle operation.

___________________

Let me know if this helps.

Joe

Images (Click to make bigger)

Thursday, July 1st, 2021 AT 9:46 AM

(Merged)