Hi Lukas,

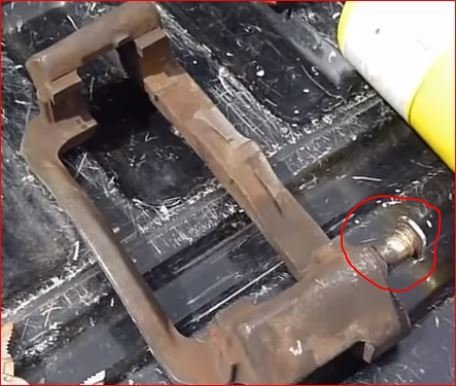

Are you trying to remove the bolt from the slide pin that holds the caliper on or the actual slide pin from the caliper bracket? Picture of the caliper bracket below.

I assume you are trying to remove the actual bolt since you mentioned the T55 bit. If this is the case, more than likely this bolt is cross threaded which means with the repeated heat cycles the bolt has gone through it may not come out.

You can try to heat them with a small plumbers torch but just make sure you remove the brake line and drape everything you don't want to get hot with a welders blanket or some other heavy fabric so they don't get hot. Lastly keep a fire extinguisher close because you don't want to get caught off guard with some oil you didn't see. This should be a last resort because anytime you are dealing with open flame around your vehicle, it is not good to be unprepared.

The only other suggestion that I have is you will need to grind or cut the bolt head off so you can wiggle the caliper off the bolt. Then most likely you will need to replace the caliper bracket because I doubt you will get this out of the bracket.

Let me know what you think and I can see if I can come up with other ideas if you don't feel comfortable doing these. Unfortunately, we are scrapping the bottom of the barrel because you named most of the easiest and most successful techniques. Thanks.

Image (Click to make bigger)

Tuesday, February 23rd, 2021 AT 8:52 AM