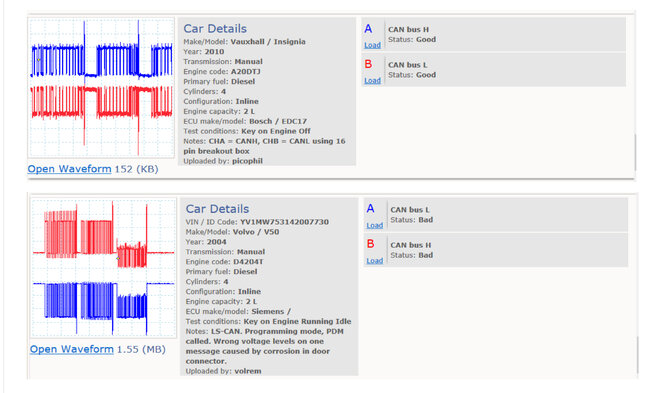

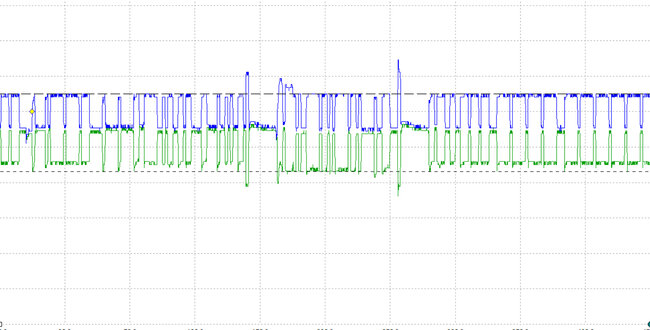

This first example is a known good (upper) and known bad (lower) from the Pico library,

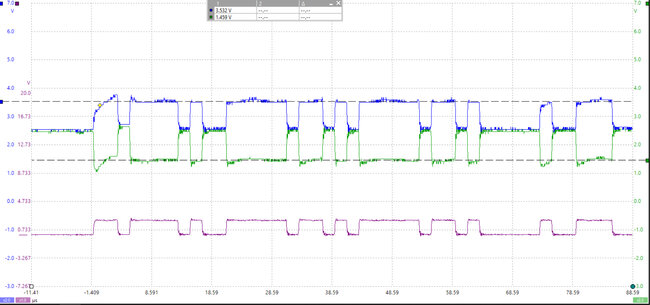

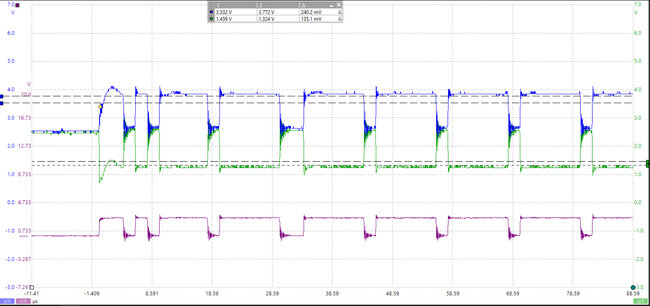

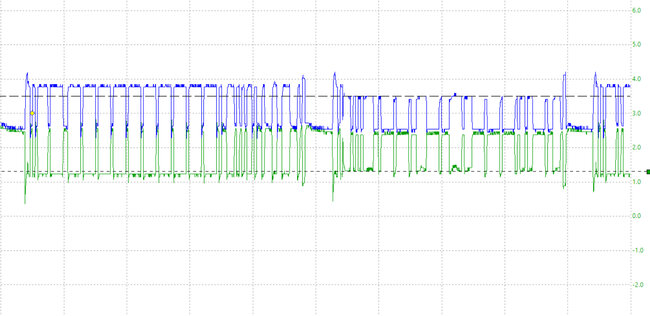

the 2nd one is a vehicle I did some engine work on and noticed some codes setting during my prescan so I scope the bus to see what it looked like, ignore the purple waveform at the bottom, that's a math channel, the Blue is the Can High signal and the green is the Can Low, right off the bat, you can see a sloping waveform, but this is only the beginning section of one message. You can see the same effect in the 3rd waveform.

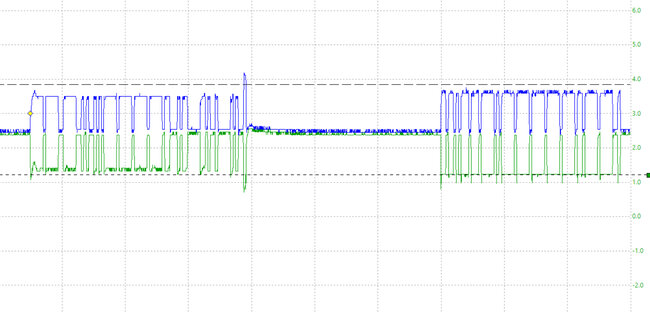

Waveforms 4, 5, 6 you can see I started to measure the voltage levels of each message packet, this is how you can tell the different modules talking on the network, some modules will have slightly different voltage levels depending on the wiring to that module or the distance from the data link connector, also any possible corrosion in connectors, But Can bus is a very robust 2 wire network and will still be able to transmit even with some wiring issues. Which is why this vehicle still running fine and still does, but it's obvious there's some wiring issues somewhere. In some cases, you will see much more obvious slopes in the waveform, or a waveform that is completely distorted.

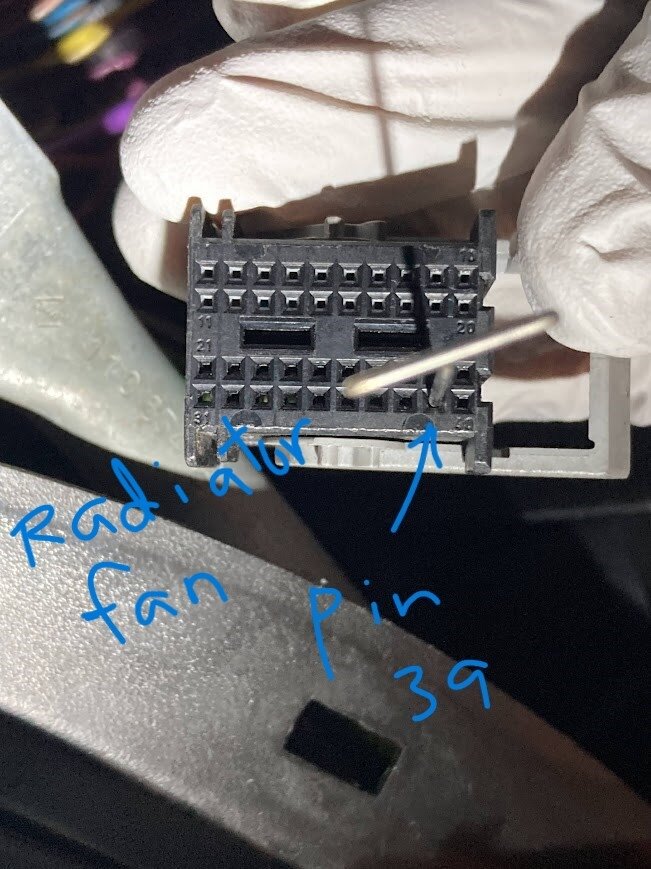

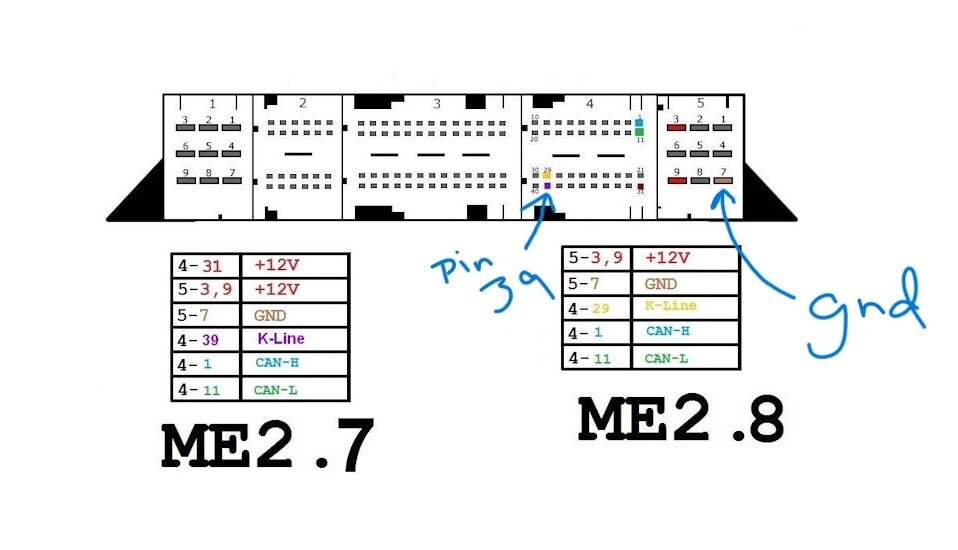

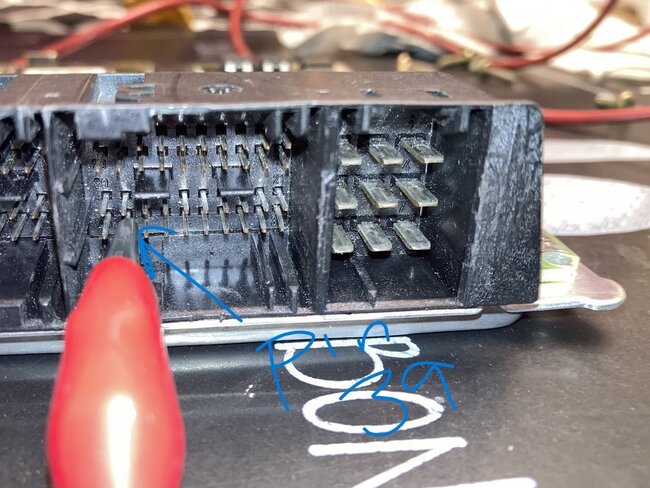

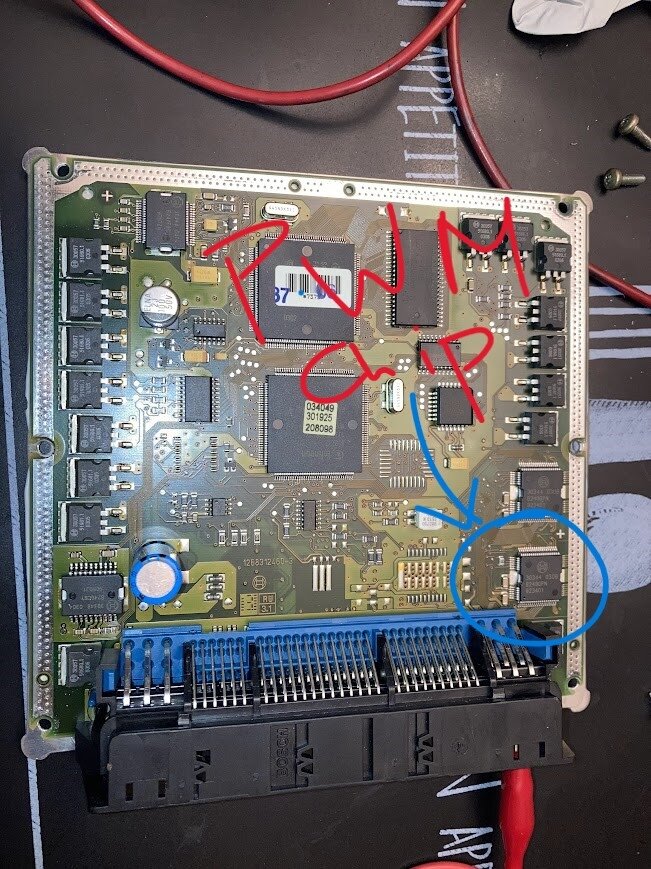

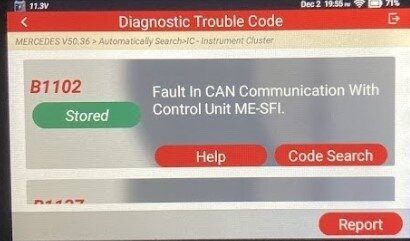

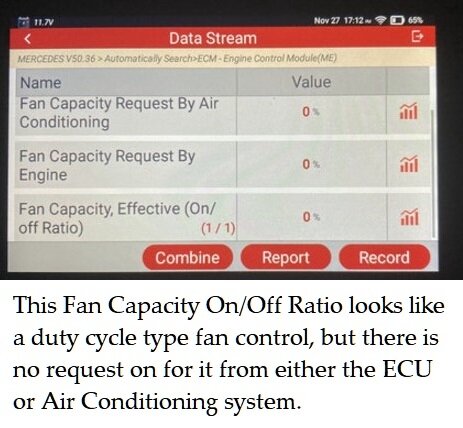

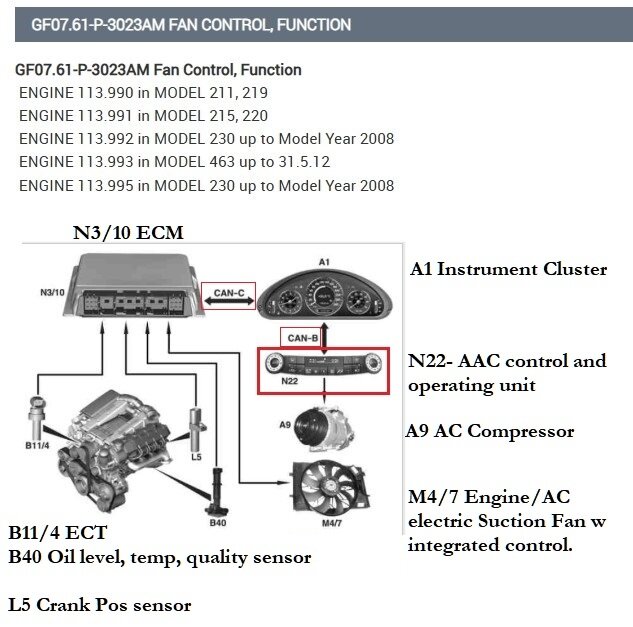

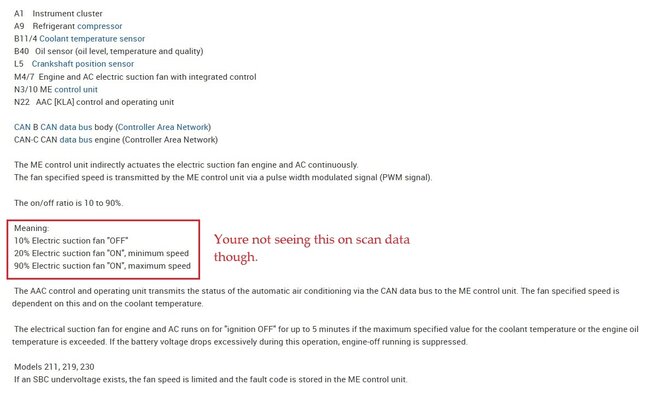

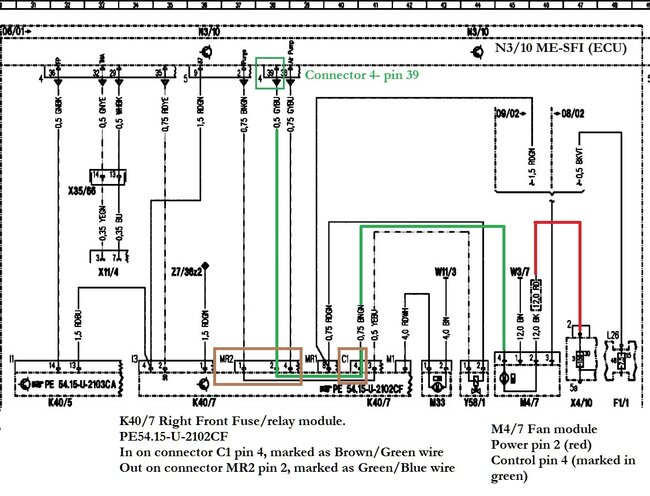

You're getting some communication codes, so some module is not seeing another module on the network that it should be, I don't work on these vehicles because I just don't run into them at all in my area and I do a lot of mobile work, but I have seen these with the fan stuck on high with a no communication issue to the ECM.

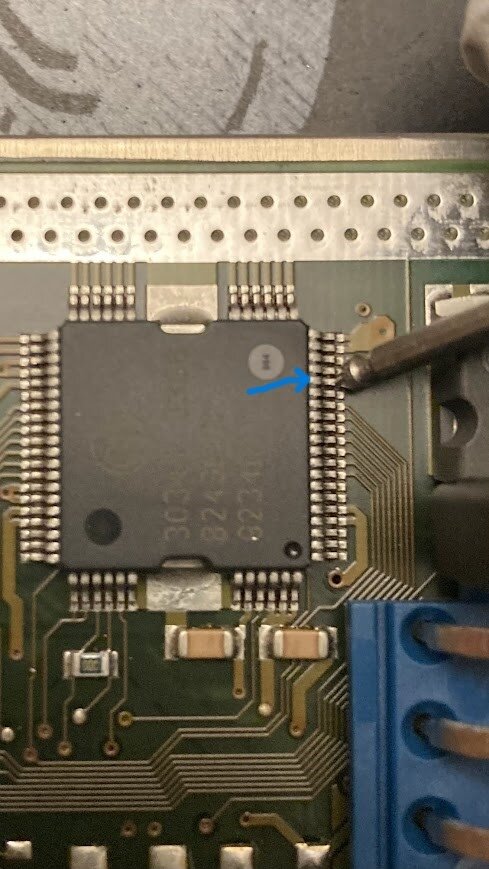

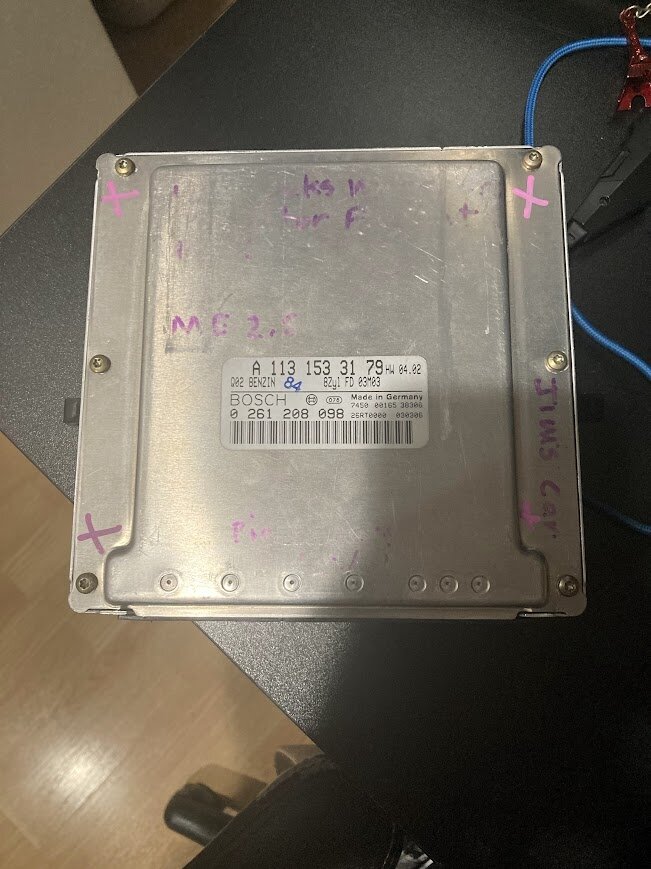

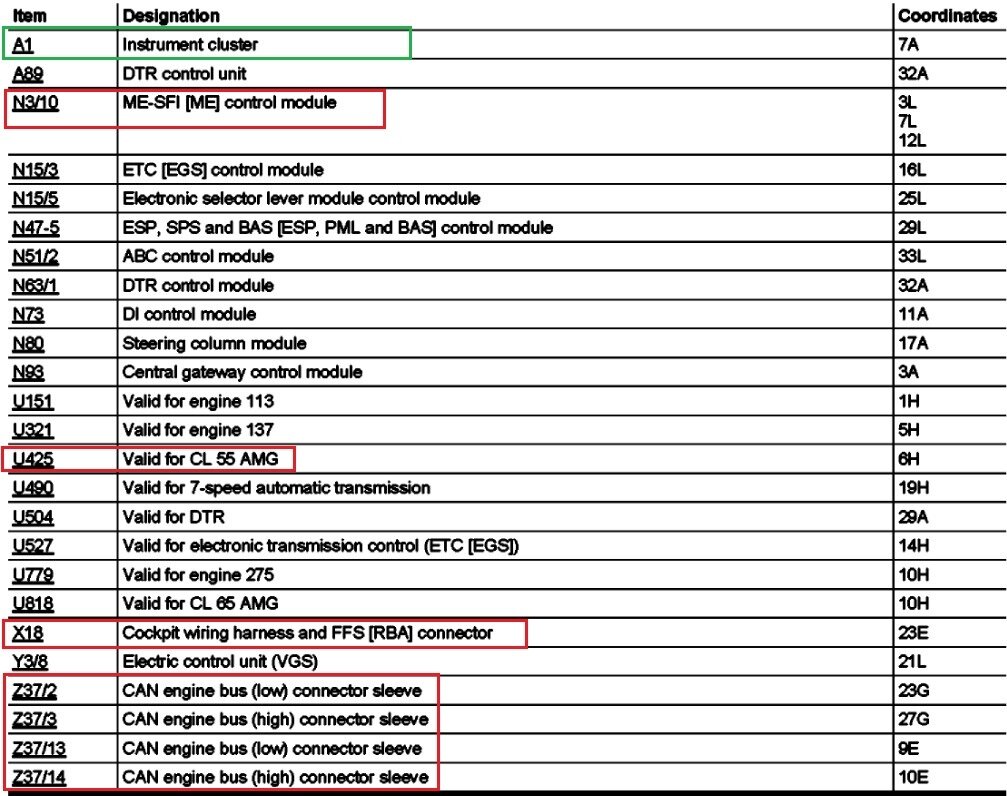

The fact that you may not even have the correct ECM now is going to make things more difficult, but the vehicle runs, this code B1102 (and I don't know if that code number is correct or not) regardless, it's the Instrument Cluster complaining that it cannot communicate with the ECM. It does say if it's a Current or Historic code, but the Instrument Cluster is on the "Engine" Can Bus network along with the ECM (ME-SFI) which makes sense, since it's the Fan running on high that is the complaint right now, but the rest of the communication codes could all be related,

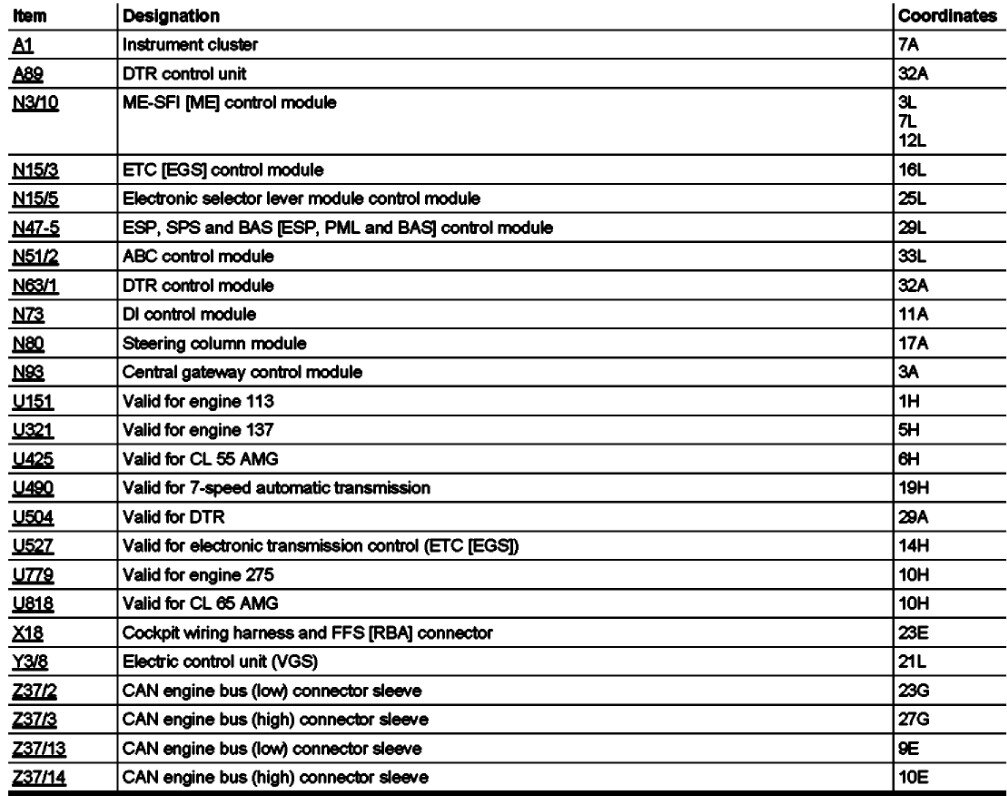

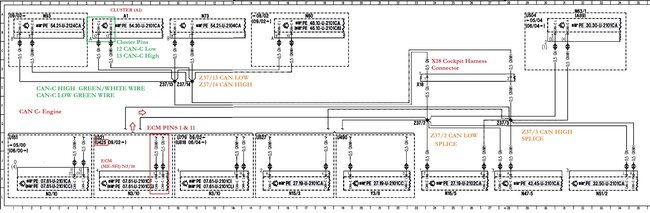

These vehicles have some many modules, diagram 8 is a list of the modules on just the Engine Can network, it might be that the Cluster and ECM cannot talk so the ECM has no way of knowing what the engine temperature might be, and therefore is defaulting the fan to high because of that reason.

What codes come back if you erase them all, (write all the codes down you have right now first) then see what comes back right away. It might take 1 or 2 drive cycles to trip a code,

but you can also go into the Cluster's live data and the ECM's live data with your scan tool and see if there's a difference in ECT data,

If your scan tool shows a network topology, it should show which modules are offline, some scan tools can do that some can't. I think yours show a topology or map of the networks, but these are just plain difficult vehicles to work on if you don't work on them all the time.

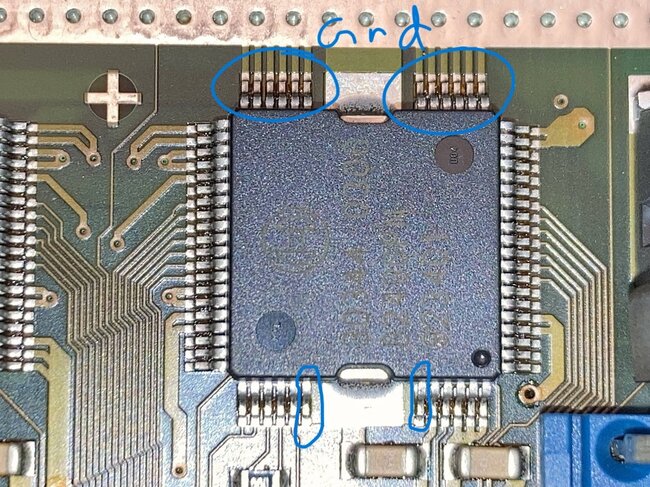

Another reason I stay away from them, and BWM, Jag, etc. Ya just end up in these situations that take forever, The Can wires between the Cluster and ECM are supposed to be

Green/White and Green. So, a twisted pair of those two wires will be your engine can bus.

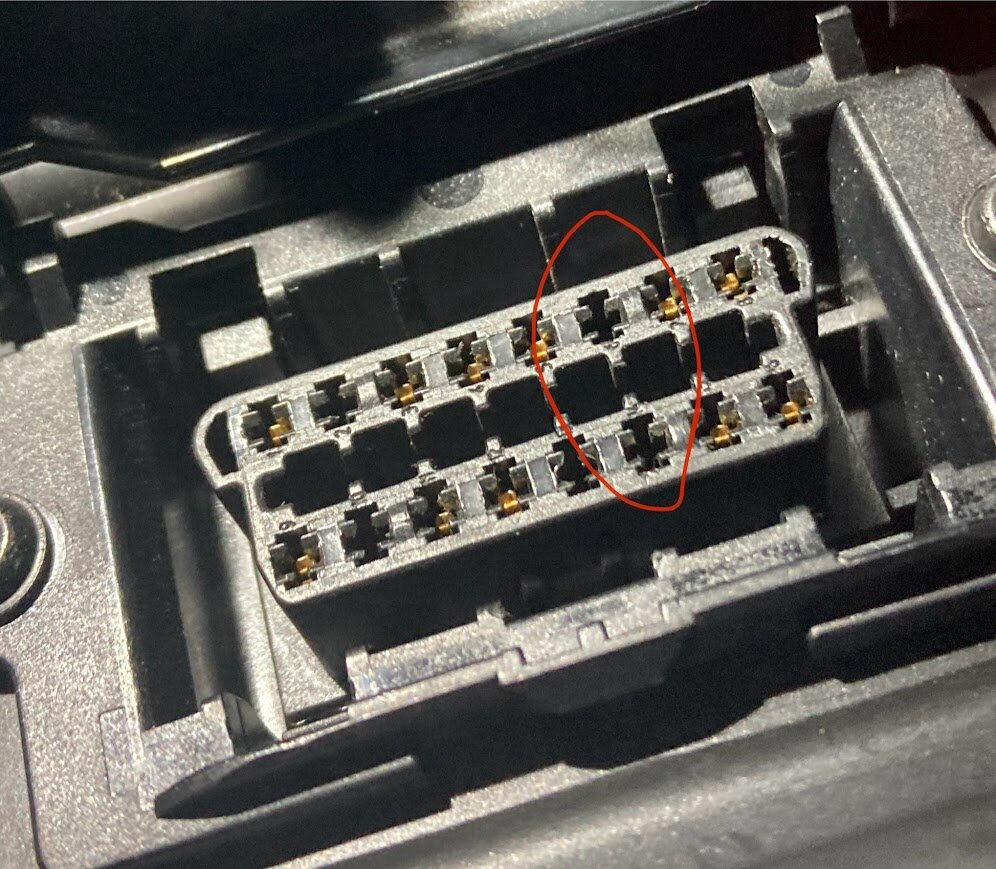

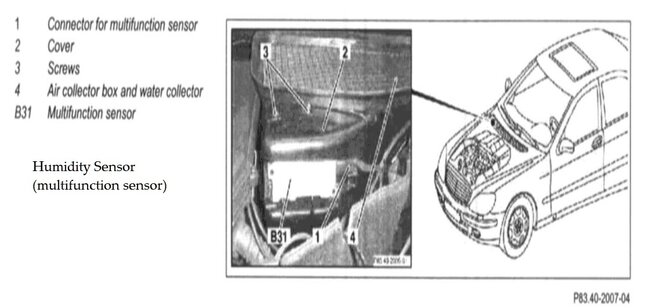

This vehicle is older, so I suspect a wiring issue, water intrusion into connectors is what I find the most.

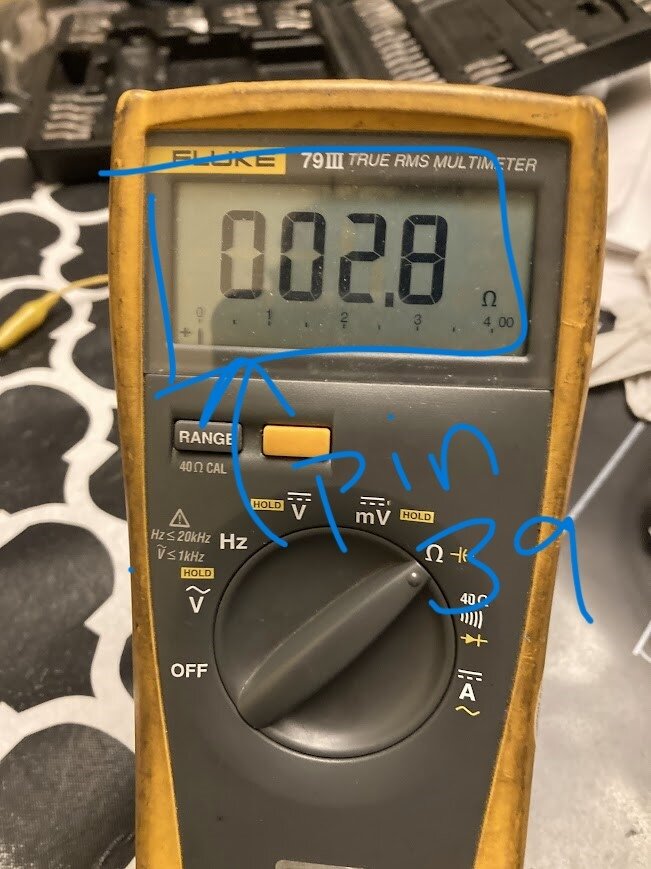

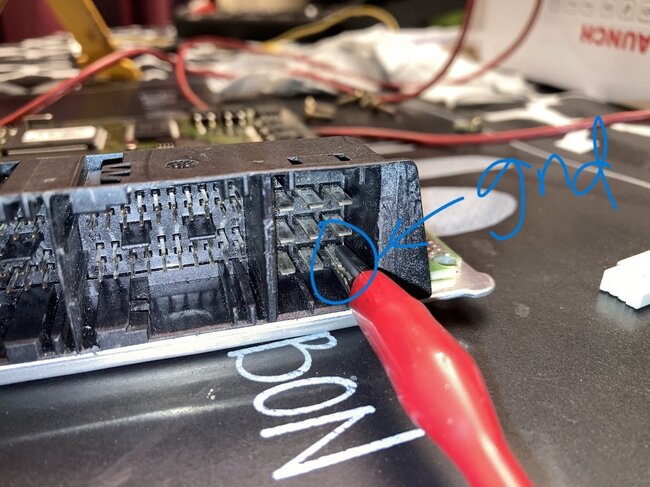

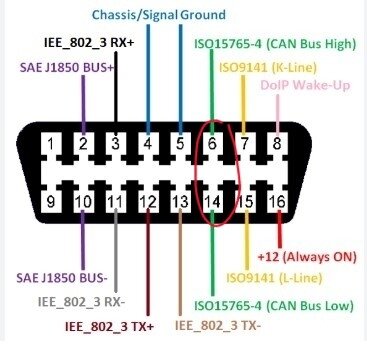

One last thing, your can bus resistance should not be 120 ohms, it should be 60 ohms between Can High and Can Low, so with the key Off, measuring between pins 6 and 14 should read 60 ohms. If you are reading 120 between 6 and 14, then one side of the network is open. You are reading 1 terminating resistor on the network. There should be (2) 120-ohm resistors in Parallel. It's also best to read the resistance of the network with the battery disconnected, stray voltage will change your ohms reading,

If you want me to post the engine bus diagrams I will, but see what codes come back first, and check some easy to access connectors for corrosion, especially ones exposed to the elements.

Sorry for the long post.

Images (Click to make bigger)

Sunday, December 8th, 2024 AT 12:18 PM