Based on your description that the pulley is loose and you have no power steering assist, it sounds like the shaft of the pump is broken. I ran into that once quite a while ago, but the broken shaft wasn't apparent until the belt was removed, then the shaft could be pulled out of the pump, with the pulley still attached. There was no tell-tale leakage around the front seal.

The loss of power assist can also be due to an internal leak in the steering gear. If your truck has rack and pinion steering, you most commonly lose power assist in just one direction first, then the other direction a few weeks later, and the assist typically comes back at first when the fluid gets warm. That type of failure gets progressively worse over a few weeks until the assist eventually never comes back. If you have the older common steering gearbox, I don't remember ever running into one that caused a loss of power assist. For those, the pump is the better suspect.

Some truck models also use a computer module to provide variable power assist depending on road speed. I think those are mostly used with rack and pinion steering gears. They can cause loss of power steering assist too.

Given the cost of parts, the need to switch the pulley, the special tools required, and the very low failure rate, the better solution would be to get a good used pump from a salvage yard. Everything I found is just the pump, some with the reservoir and some that you need to reuse yours, but they all come without the pulley. That's because the same pump can be used on many different models and years, but with different pulley diameters, number of grooves on the pulley, and varying depth the pulley is pressed on. They only have to inventory one pump that way to cover all the models.

The next issue is you will need a special pulley puller to get the pulley off the old pump. You can find a set of tools at Harbor Freight Tools, but most auto parts stores that rent or borrow tools will have that set. In my city, they make you buy the tools, then you get a full refund when you return it. If you decide to keep a tool, you still return it, then they order or give you a brand new one.

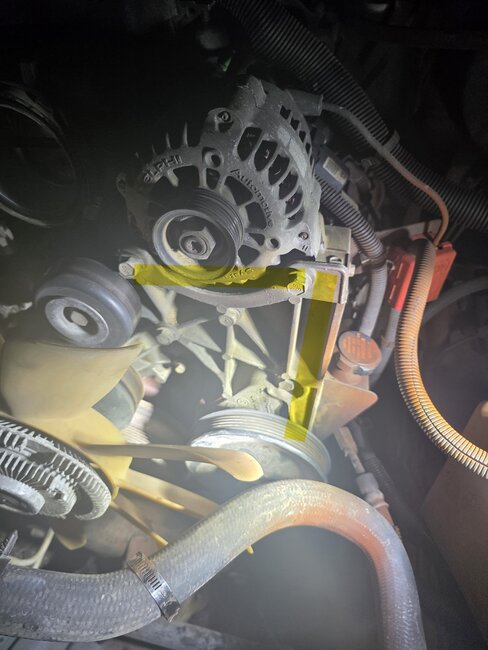

You'll notice there's a collar about an inch and a quarter in diameter around the front of the pulley. Depending on who made the tools, a one or three-piece tool goes around that lip, (blue arrow in my nifty photo), then a bolt is threaded through that tool to push the shaft out of the pulley.

The next issue is when you push the pulley onto the new pump, how far you push it on is critical. 1/16" too much or too little can set up a miserable belt squeal. Rebuilt pumps often come with a bolt that threads into the shaft's center hole, and a nut and washer to run the pulley on. While they do work once or twice, you still need that special tool set to remove the pulley and to pull it back out if you press it on too far.

One way to know the pulley is on the correct depth is to observe the ring of rust inside the pulley's center hole. After pushing the pulley on, remove the tool, then if you see any shiny area showing on the center hole, the pulley has to go on further. You can creep up to the proper depth that way, but you won't know it if you went on too far.

The better way is to use a special spacer to set the depth. I can't find a photo, so I drew two examples in the photo below, (top of photo). You chose the spacer with the depth that matches the old pulley's depth and place that on the pulley just before you attach the pulling tool. They have holes for the pulling bolt to go through. The narrow part of the spacer, (on the bottom in my drawings), hits the end of the shaft when the correct depth is reached. It won't let you push the pulley on too far. Those spacers normally do not come as part of the special tool kit. When I used these at a Chrysler dealership, the replacement pulleys and replacement pumps came with the correct spacer, then we were expected to just throw them away later. I kept them and found there were only two sizes at that time. If the pulley is pressed on flush with the end of the shaft on the old pump, you don't need or use either spacer with the new parts.

If you do go with a used pump, look at how far your pulley is pressed on, then find a pump from the same year and model and check that this pulley is on the same depth. That eliminates the need for the special tools.

I can't tell you the nut size for the pressure hose other than to suggest it's most likely metric. Use a flare-nut wrench, aka Line wrench because these nuts will be very soft. Flare nut wrenches grab the nut in four places instead of two with standard open-end wrenches. I'd expect that nut to be 15 or 17 millimeter, but GM is famous for often using the very uncommon 16 millimeter too.

Sorry about the photos not working. That should be solved after the site is finished being updated.

Images (Click to make bigger)

Friday, November 21st, 2025 AT 3:41 PM