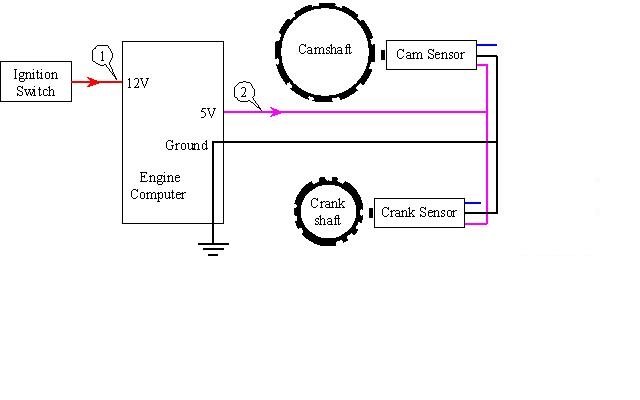

1. In the first drawing, the ignition switch is turned to the "run" position. 12 volts shows up at the Engine Computer to turn it on. (Cute little number "1" in the circle).

2. The computer generates a carefully-regulated 5.0 volt power supply to run multiple sensors, including the cam and crank sensors. That 5.0 volts feeds the two sensors on the purple wire. The ground return wire is common to all the sensors on the engine. It goes through the computer so it can be monitored. At this point, the sensors are waiting to start detecting movement of their sprockets or tone rings by looking at the notches cut into those sensor rings.

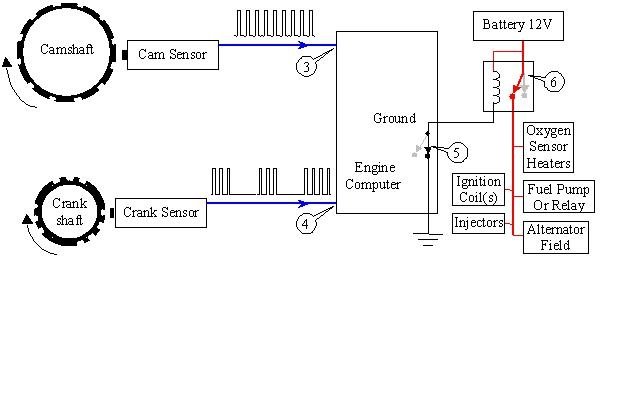

In the second nifty drawing, the sprockets are rotating, either from the starter cranking the engine, or because the engine is running. Each time a notch passes by the tip of the sensor, a pulse of voltage is generated. It is amplified by each sensor's internal circuitry to send out pulses that switch between 0.0 and 5.0 volts.

3. The camshaft sprocket is shown with 12 notches, but the actual number will vary between engines and years. I think yours only generates two pulses per revolution. When an engine uses an ignition coil pack with two, three, or four individual coils, the notches will have offset spaces and gaps so the computer can figure out which piston is coming up on top dead center. That's how it knows which coil to fire. When you have a distributor, it's up to the position of its rotor to send spark voltage to the correct spark plug. The computer only has to know when to fire the one ignition coil. It doesn't know which cylinder it's firing.

4. The crankshaft sprocket has three groups of notches with a different number of notches per group. With this arrangement, the computer knows which pair of pistons are coming up on top dead center. One will be on the compression stroke, and one will be on the exhaust stroke. Both spark plugs fire at the same time. Once the crankshaft rotates at least one full revolution, the computer will know which ignition coil to fire when it sees the oddball number of notches.

With this design, the signal pulses from the crankshaft position sensor just tell the computer which cylinders to fire next. It's the signal from the camshaft position sensor that tells it very precisely when to fire that spark plug. The opposite is true for some other engines. It can be the camshaft position sensor that tells the computer which coil to fire, and the crankshaft position sensor is the one that dictates the precise spark timing. Some engines use one signal for precise spark timing and the other one for precise injector timing. We don't need to know that. We only care that both signals are there.

5. When the computer sees both signals at "3" and "4", it turns on its internal switch to ground the coil inside the automatic shutdown, (ASD) relay.

6. Energizing the ASD relay turns on its high-current switch, ("6"), and that sends current, on the red wires, to all the circuits shown.

The fuel pump is grounded already, so it runs. The computer grounds the oxygen sensor heaters to make them operate. It grounds the injectors for a very short, pre-programed amount of time to allow them to spray fuel into the intake manifold, then that ground is turned off until the next squirt of fuel is needed. The ignition coils are just the opposite but work the same way. The computer keeps them grounded so a nice big electromagnetic field builds up inside them, then it turns that ground off the exact instant it wants that coil to fire a spark plug. The magnetic field built up relatively slowly when the ground was turned on, but when the ground is turned off, that really strong magnetic field has no choice but to collapse instantly. That really fast movement of that collapsing magnetic field is what induces the really high voltage in the primary part of the ignition coil, then that is seriously-multiplied in the secondary part where the spark voltage is developed. The computer turns the ignition coil's ground off at the precise time it wants a spark, then it turns that ground back on as soon as possible to give the magnetic field plenty of time to build up for the next event.

The purpose of this system is if the fuel line is ruptured in a crash, the electric fuel pump would keep on dumping raw gas onto the ground where it would be a major fire hazard. With a broken fuel line, there can't be any pressure in it. With no pressure, no fuel will spray from the injectors. That causes the engine to stall. Once the crankshaft and camshaft are no longer rotating, the two sensors stop generating signal pulses. The computer sees that as it's time to turn the ASD relay off. That kills the 12 volts going to the fuel pump.

The only difference on your car is the fuel pump is fed its 12 volts through its own fuel pump relay instead of through the ASD relay. Both relays get turned on and off at the same time, just by different circuits in the computer.

There's three ways the engine can have a crank / no-start problem. The least common is when the ignition coil fails, as it appeared was the case with your car. The symptom is no spark. The next way is the fuel pump fails. The symptoms are you'll have spark, but no fuel pressure. By far, the most common failure is when one of the sensors fails. The computer turns off the ASD relay, so that results in no spark AND no fuel pump, AND no injector pulses. Where many people become confused is the pump still runs for one second each time the ignition switch is turned on, and that is why there is fuel pressure in the line, when it is checked.

Images (Click to make bigger)

Monday, January 29th, 2018 AT 7:25 PM