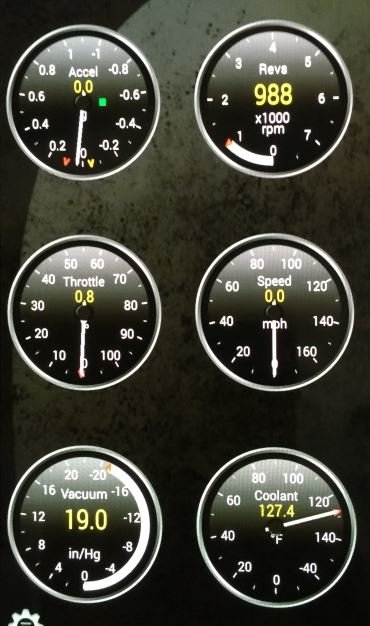

The car runs fine, starts fine, no issues otherwise.

I read this can be caused by the following:

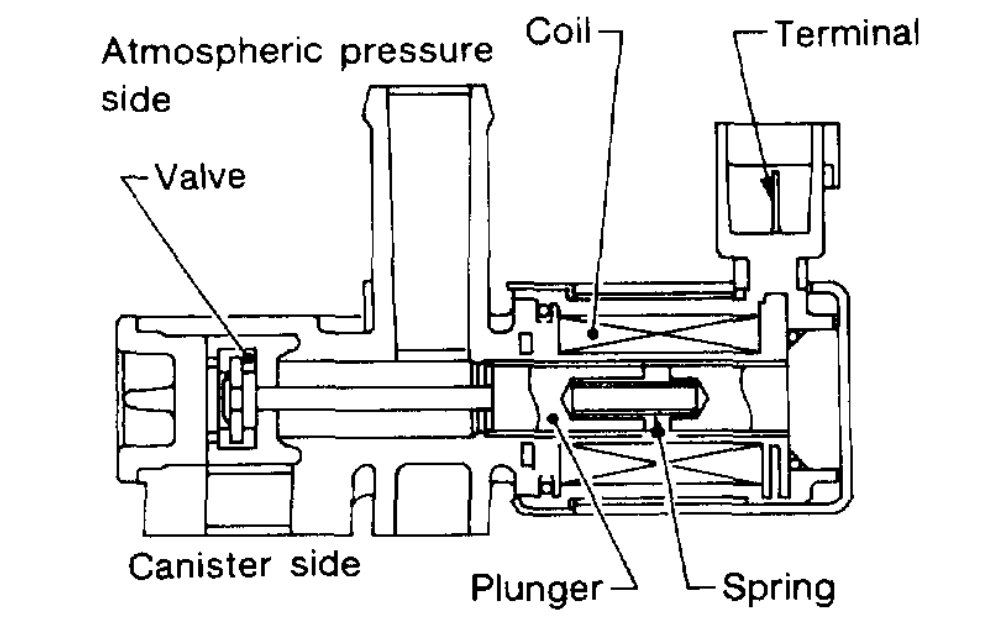

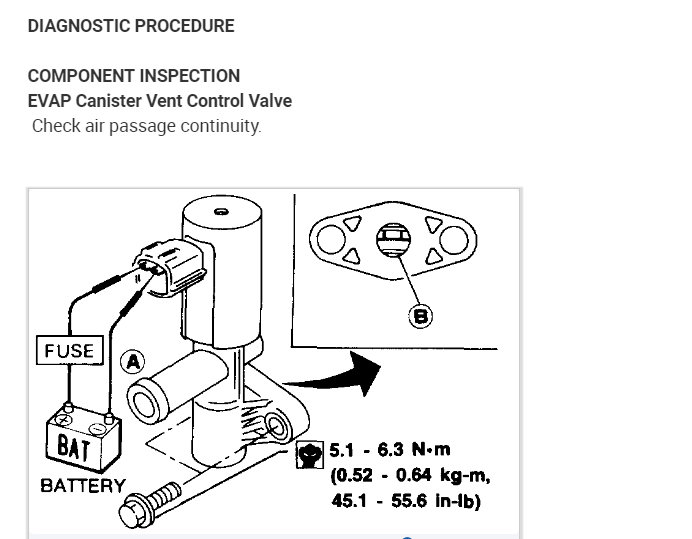

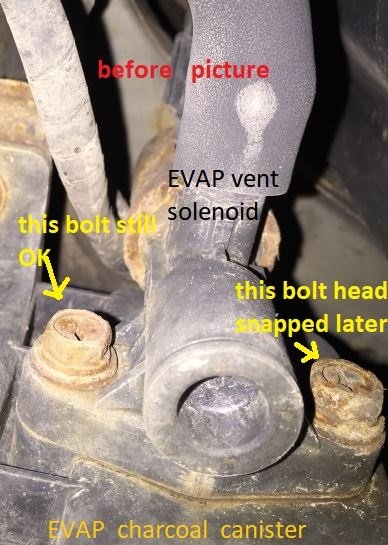

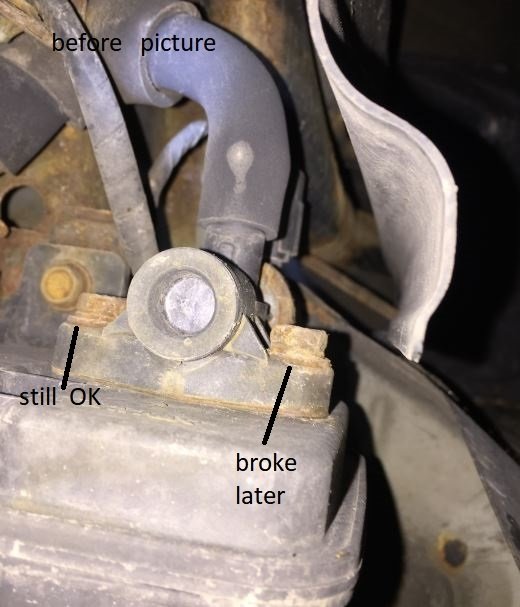

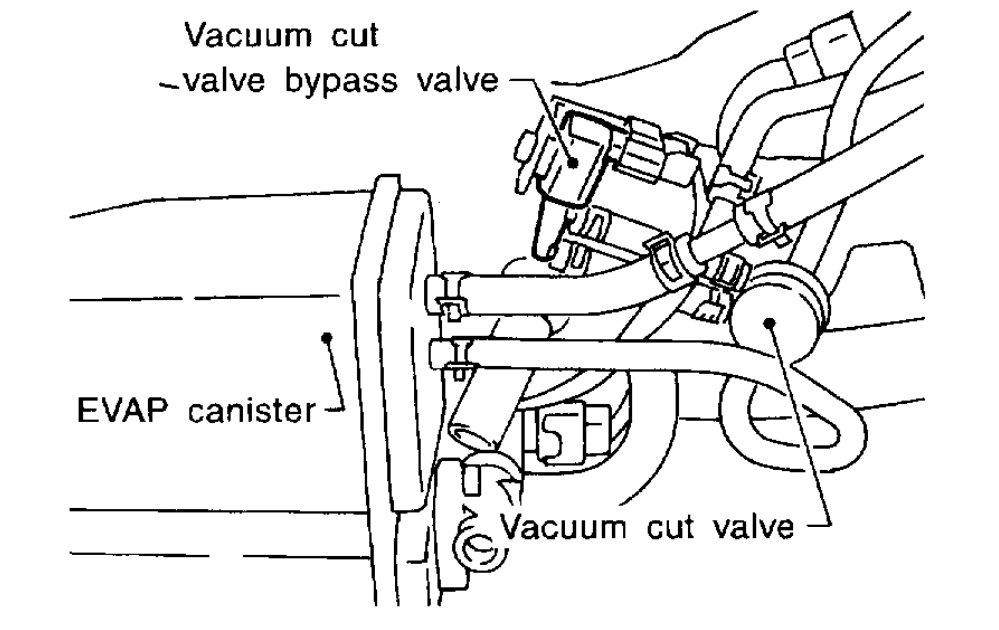

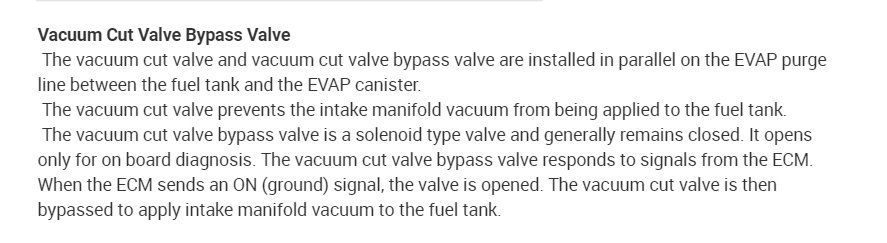

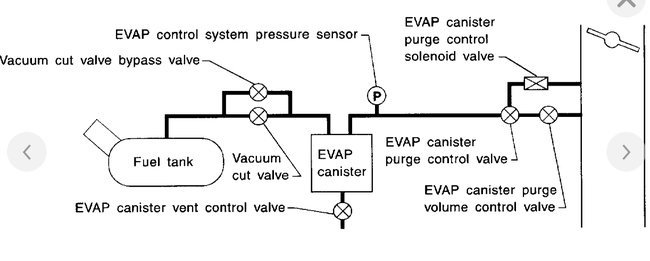

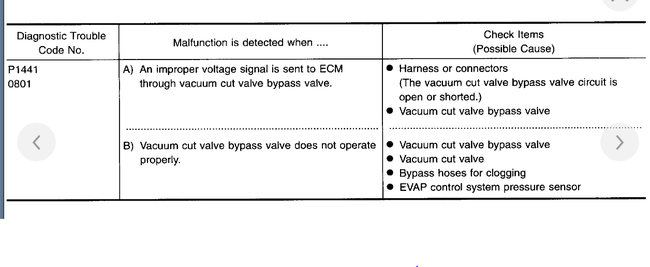

Bad gas cap, intake manifold hairline crack, bad hose, cracked charcoal canister, EVAP vent control valve solenoid not closing properly, bad EVAP canister purge valve.

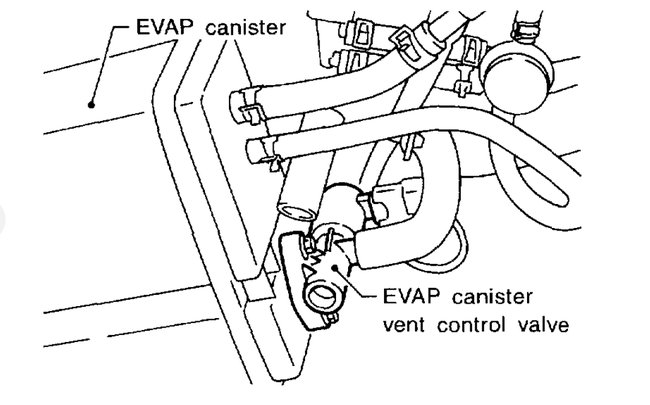

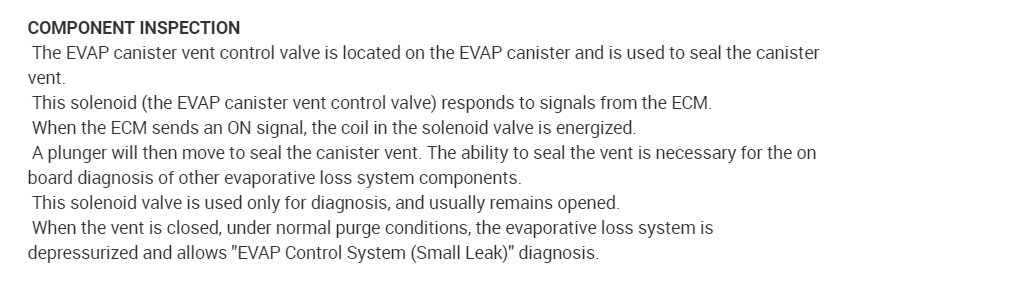

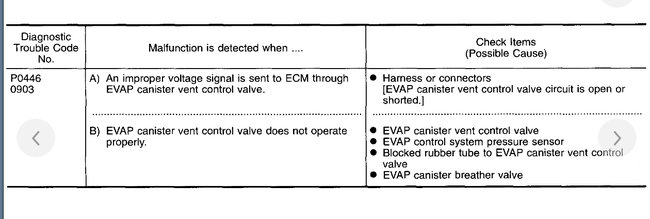

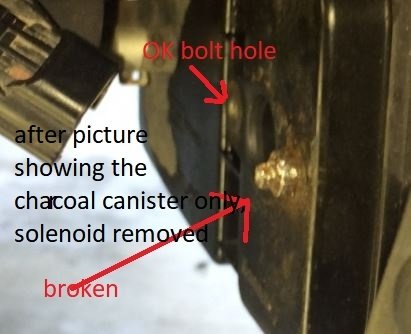

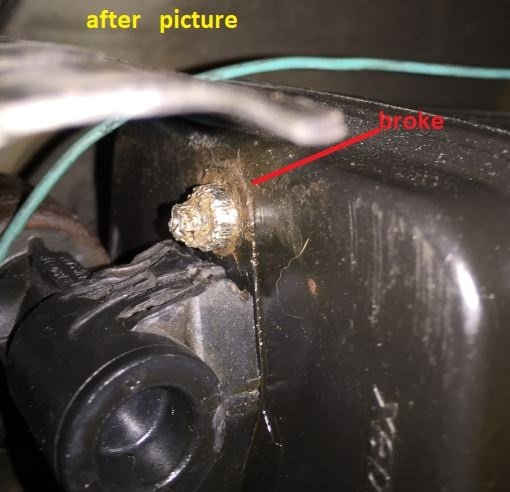

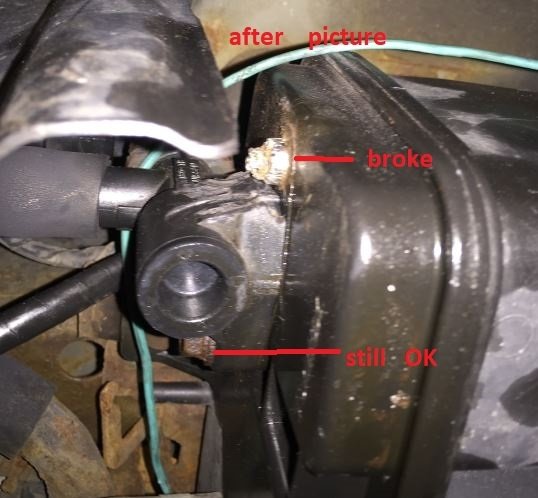

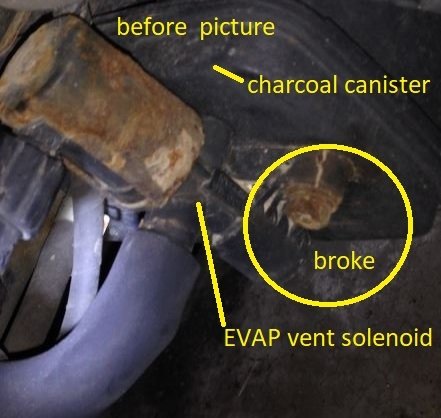

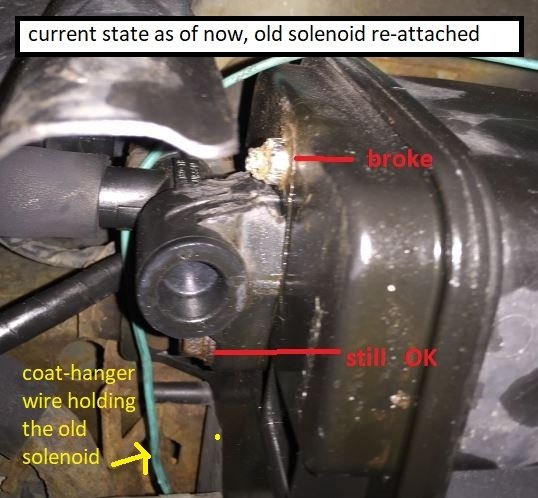

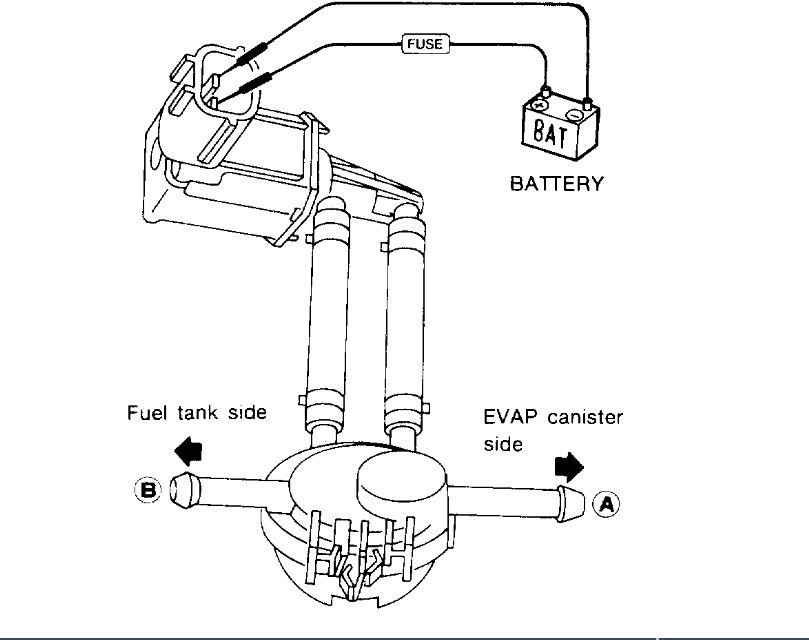

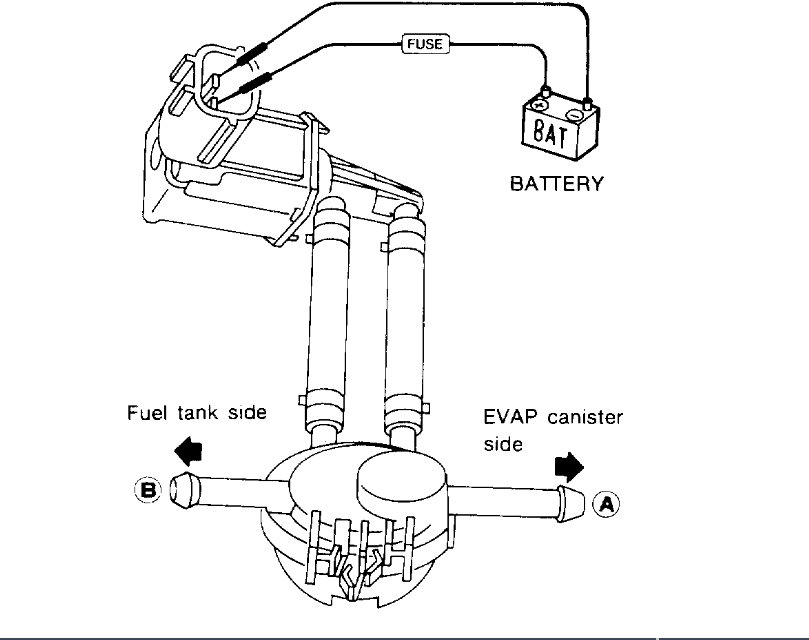

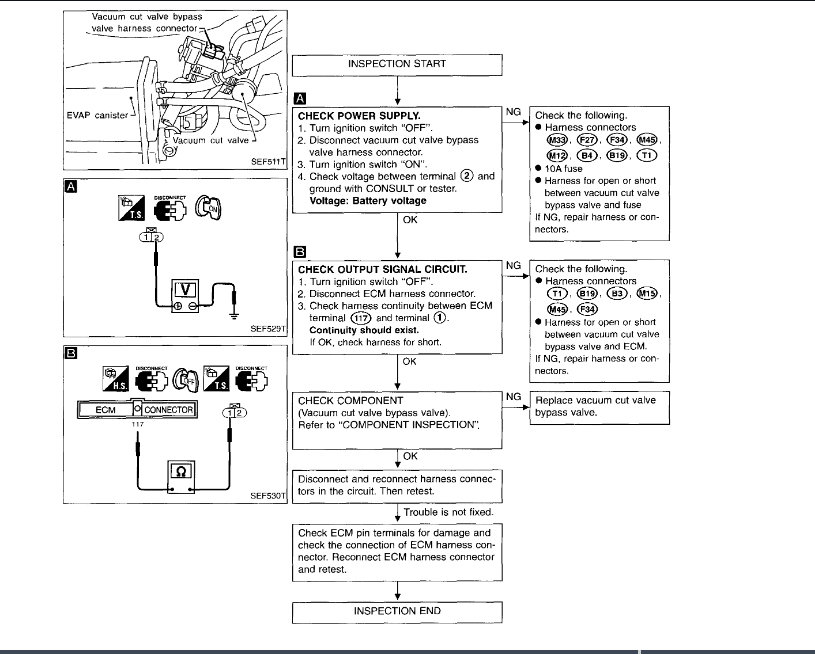

I checked the usual suspects and I'm down to 3 possibilities, the charcoal canister, the EVAP vent valve/solenoid, the EVAP purge valve/solenoid.

YouTube doesn't have any videos for replacing the canister or the vent valve for this model.

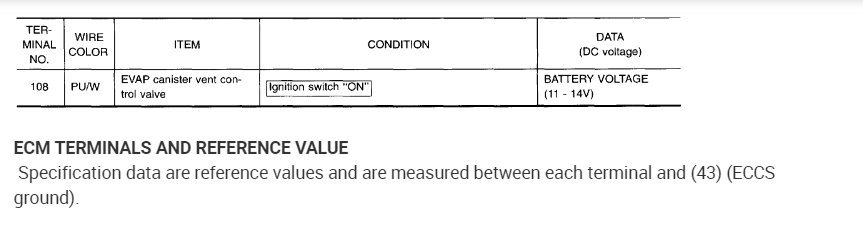

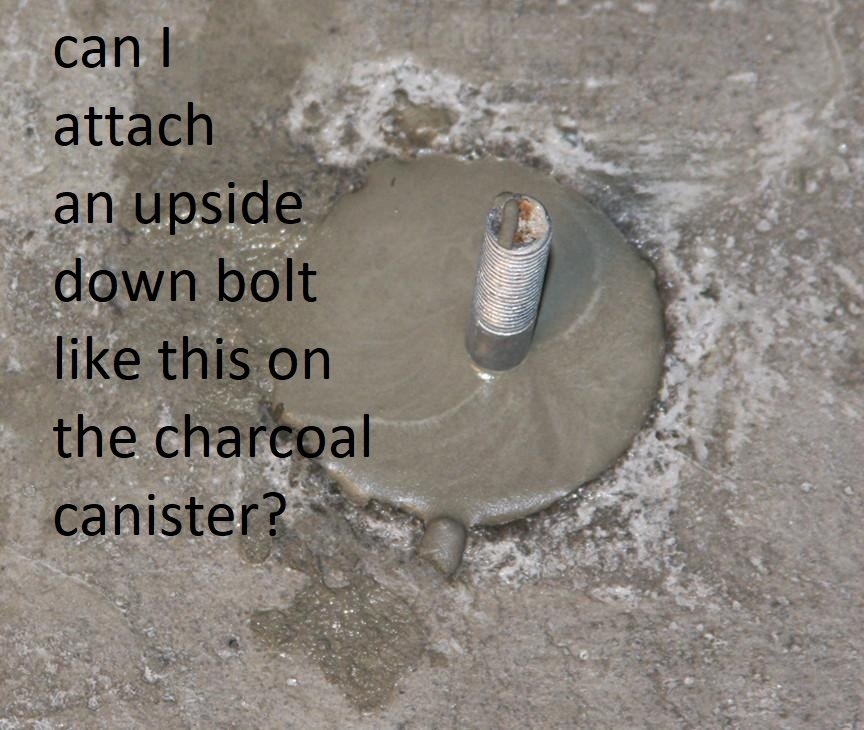

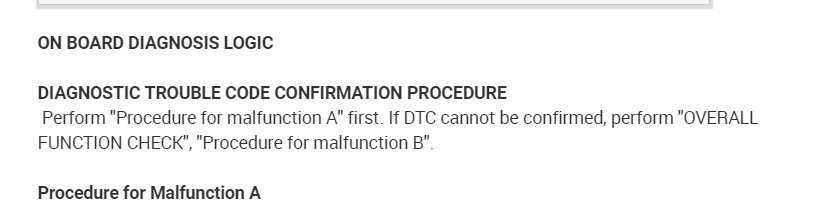

What could be causing this issue? What tests to perform to narrow down possibilities? Which item should I replace first? Is there any way to fix the parts other than buying brand new replacements?

Thursday, August 1st, 2019 AT 9:30 PM