Welcome back:

Okay, then it is most likely a bad front hub / wheel bearing. Here is how to determine which one is bad. If you make a sharp right hand turn and the sound lessens or goes away, the right front bearing is the problem. The opposite applies when turning left.

Picture the weight distribution of the vehicle. When going straight, the weight remains the same. However, when turning, right for example, much of the vehicle's weight is shifted to the left side of the vehicle. So, if the sound lessens or goes away, it's because you have removed weight off that bearing.

The reason you don't notice it when you lifted the wheel is because you took the load off the bearing. Did you check for play in and out or side to side?

Now, you also mentioned tires. If the tires are chopped, cupped, or uneven, they too can make noise so check that also. Here is a link which discusses uneven tire wear and how it is fixed.

https://www.2carpros.com/articles/how-car-tires-work

If you determine the bearing is the issue, here are the directions specific to your vehicle for replacement. You will need a bearing press to complete the procedure. The attached pics correlate with the directions.

https://www.2carpros.com/articles/bearing-press-how-to-use

FRONT

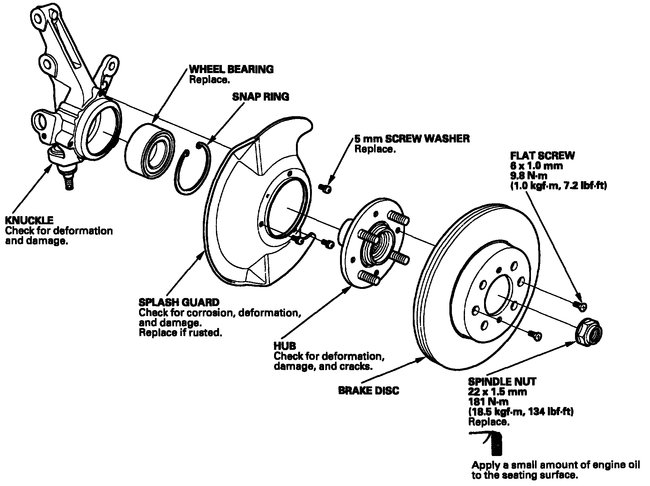

pic 1

Knuckle/Hub/Wheel Bearing Replacement

Special Tools Required

- Hub dis/assembly tool 07GAF-SE00100

- Ball joint remover, 28 mm 07MAC-SL00200

- Attachment 62 x 68 mm 07746-0010500

- Driver 07749-0010000

- Support base 07965-SD90100

1. Raise the front of the vehicle, and support it with safety stands in the proper locations.

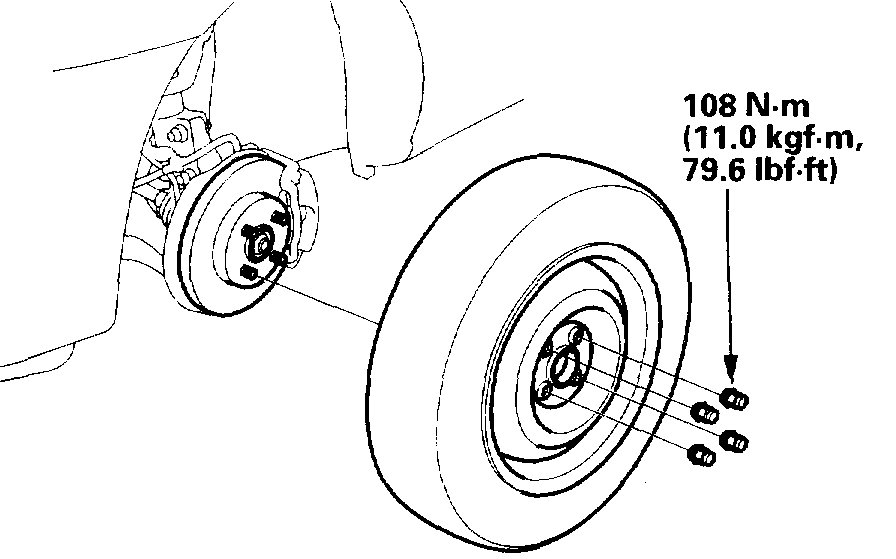

pic 2

2. Remove the wheel cap, wheel nuts, and front wheel.

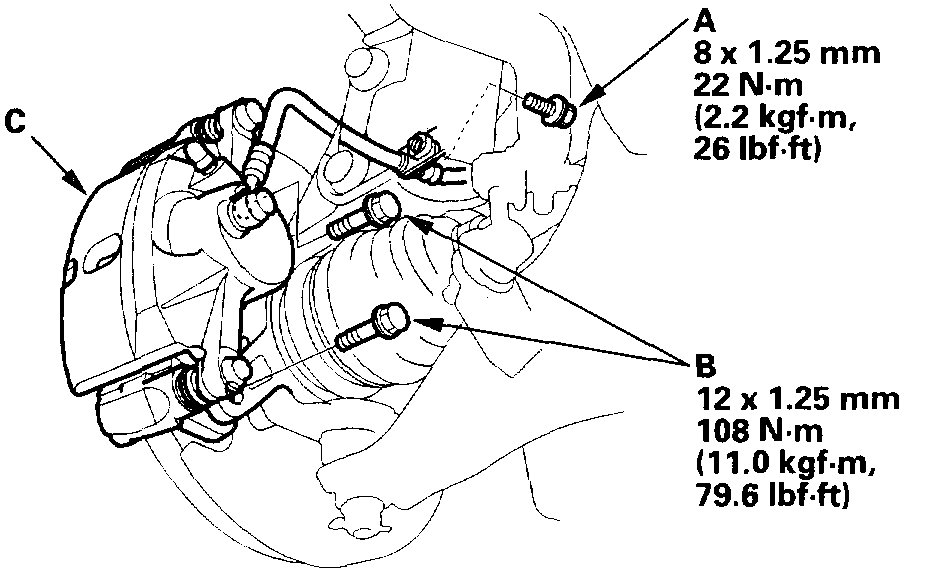

pic 3

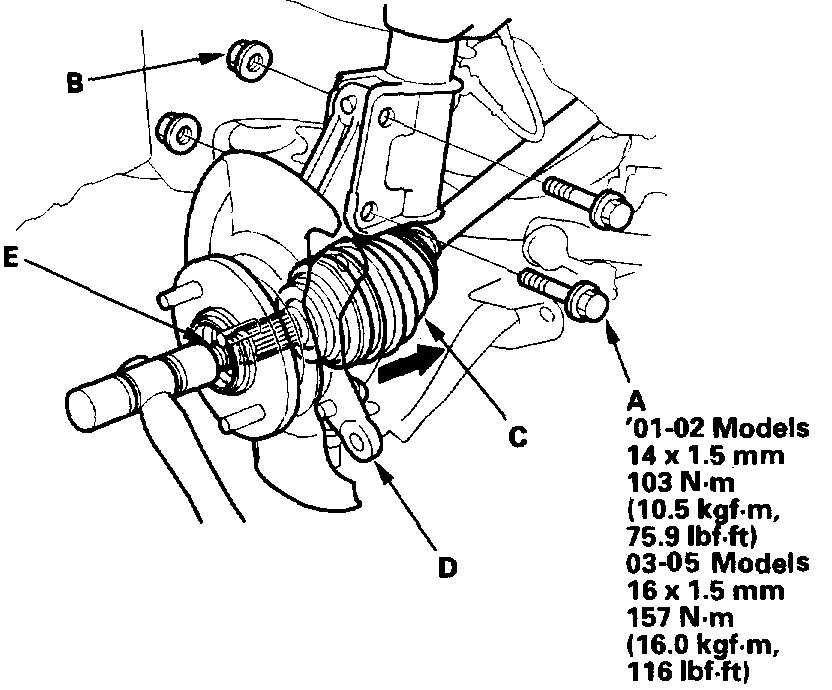

3. Remove the brake hose bracket mounting bolt (A).

4. Remove the caliper bracket mounting bolts (B), and remove the caliper assembly (C) from the knuckle. To prevent damage to the caliper assembly or brake hose, use a short piece of wire to hang the caliper assembly from the undercarriage. Do not twist the brake hose with force.

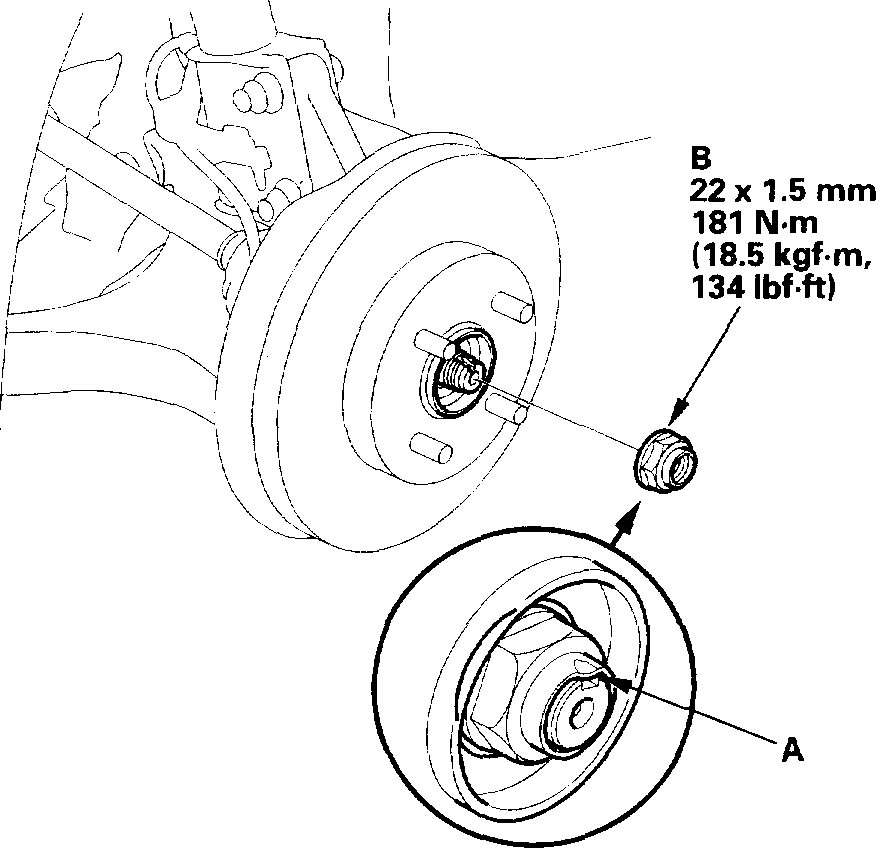

pic 4

5. Raise the stake (A), and remove the spindle nut (B), then remove and discard the nut.

pic 5

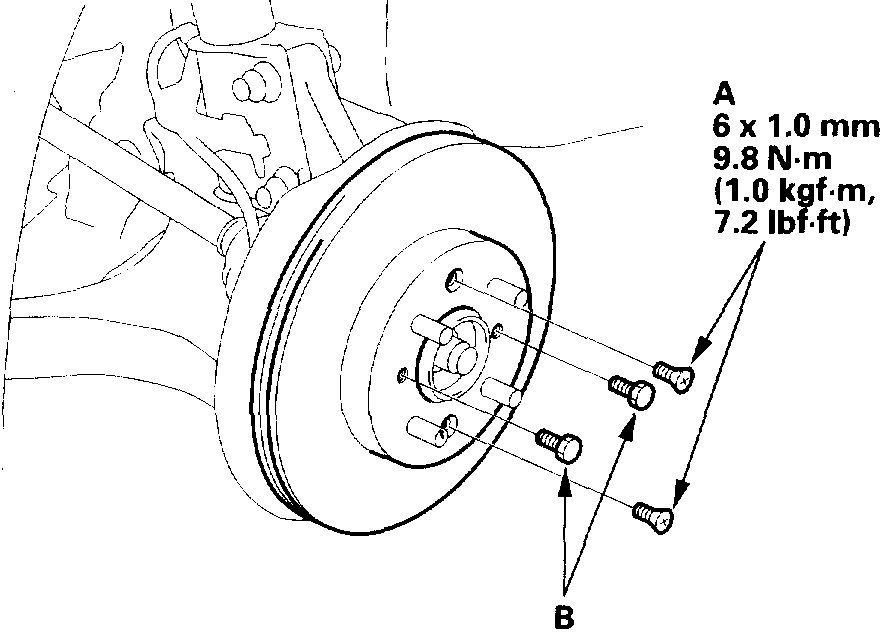

6. Remove the brake disc retaining flat screws (A).

7. Screw two 8 x 1.25 mm bolts (B) into the disc to push it away from the hub. Turn each bolt 2 turns at a time to prevent cocking the disc excessively.

pic 6

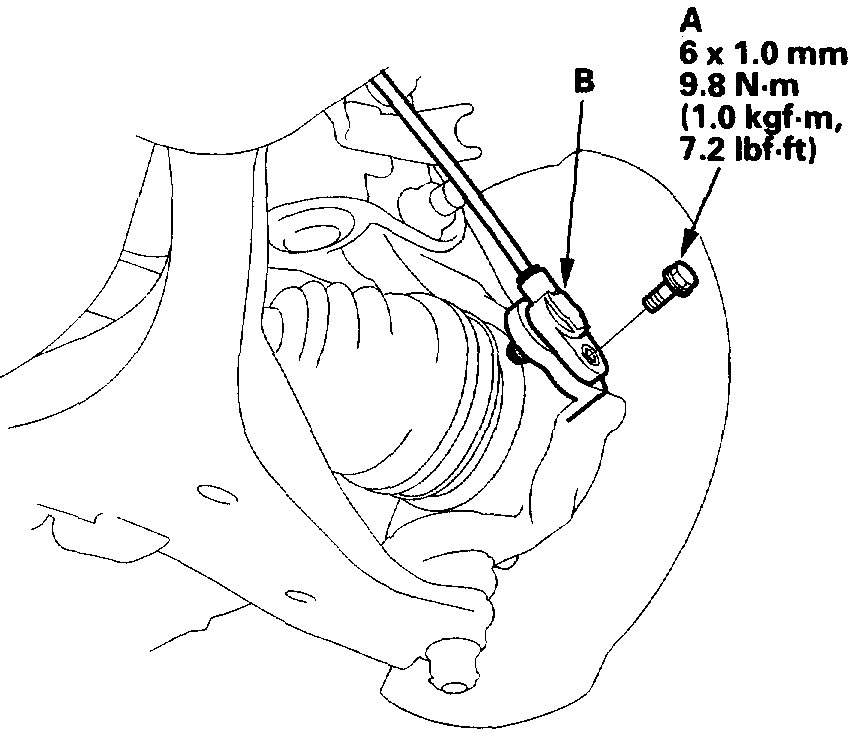

8. Remove the flange bolt (A) and wheel sensor (B) from the knuckle. Do not disconnect the wheel sensor connector.

pic 7

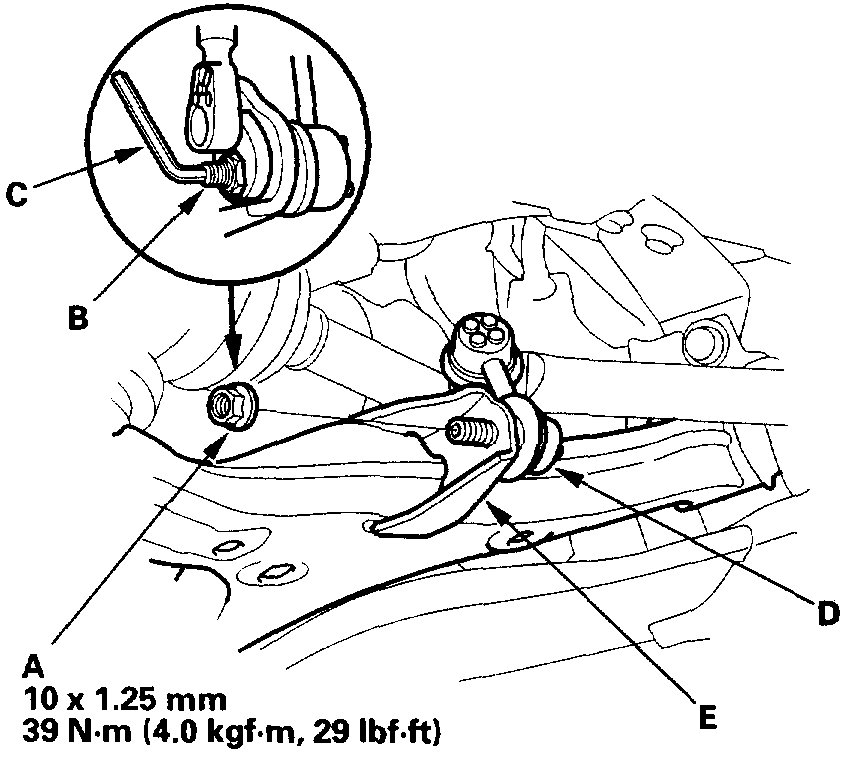

9. Remove the flange nut (A) while holding the joint pin (B) with a hex wrench (C), and disconnect the stabilizer link (D) from the lower arm (E).

pic 8

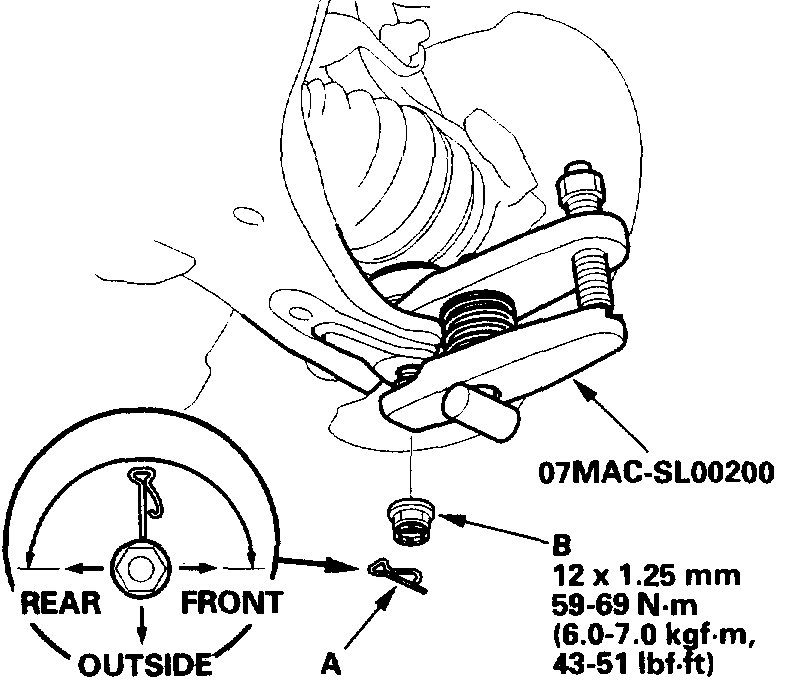

10. Remove the lock pin (A) from the lower arm ball joint, and remove the castle nut (B).

NOTE: During installation, insert the lock pin into the ball joint pin in the range of 180 degrees or below from the inside of the vehicle. Insert the lock pin from the inside to the outside of the vehicle.

11. Disconnect the lower arm from the knuckle using the special too.

pic 9

12. Loosen the damper pinch bolts (A) while holding the nuts (B), and remove the bolts and nuts.

13. Remove the driveshaft outboard joint (C) from the knuckle (D) by tapping the driveshaft end (E) with a plastic hammer while pulling the knuckle outward, then remove the knuckle.

NOTE: Do not pull the driveshaft end outward. The driveshaft joint may come off.

pic 10

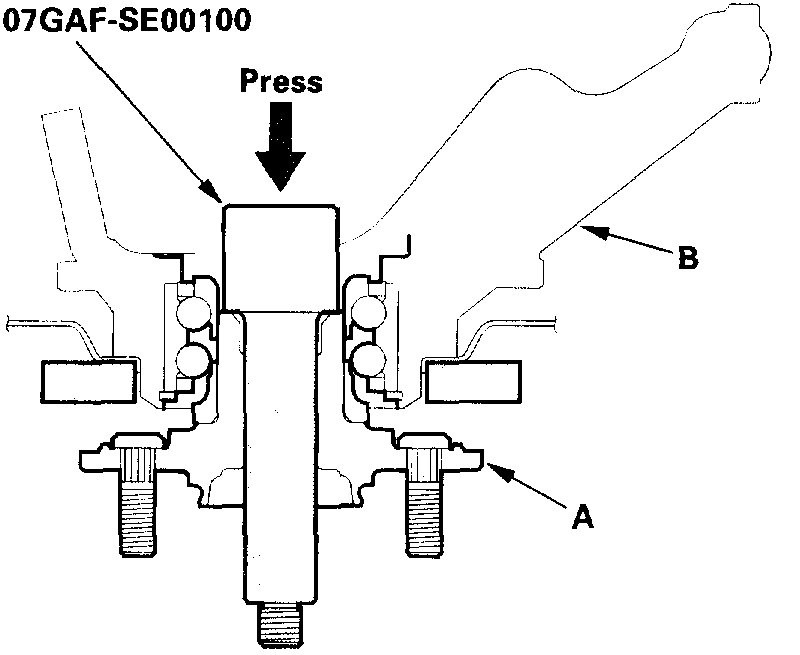

14. Separate the hub (A) from the knuckle (B) using the special tool and a hydraulic press. Be careful not to deform the splash guard. Hold onto the hub to keep it from falling when pressed clear.

pic 11

15. Press the wheel bearing inner race (A) out of the hub (B) using the special tool, a commercially available bearing separator (C), and a press.

pic 12

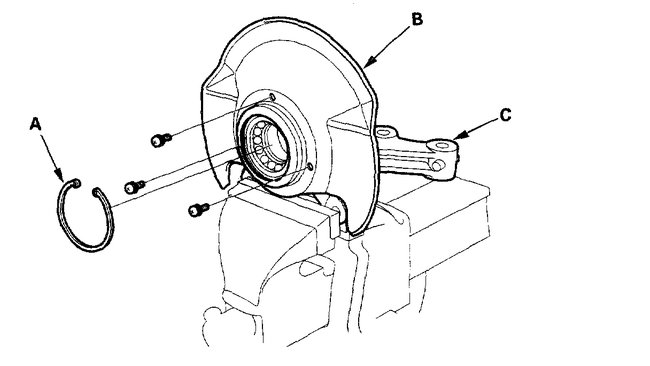

16. Remove the snap ring (A) and the splash guard (B) from the knuckle (C).

pic 13

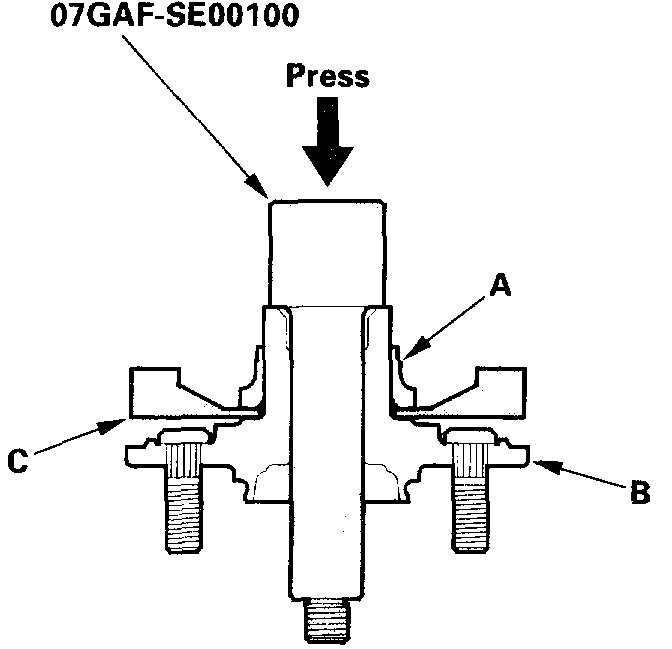

17. Press the wheel bearing (A) out of the knuckle (B) using the special tool and a press.

18. Wash the knuckle and hub thoroughly in high flash point solvent before reassembly.

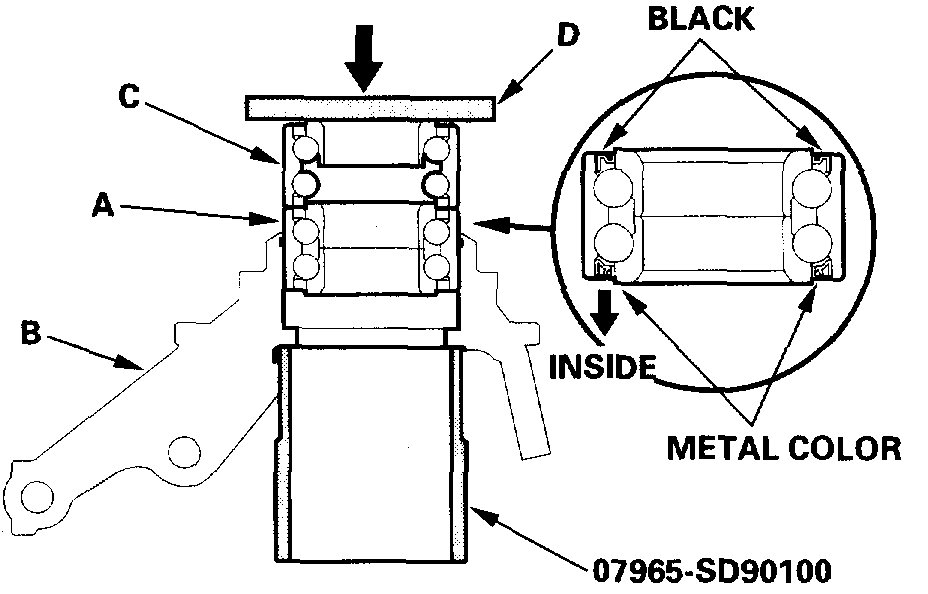

pic 14

19. Press a new wheel bearing (A) into the knuckle (B) using the old bearing (C), a steel plate (D), the special tool, and a press. Place the wheel bearing on the knuckle with the pack seal side facing (metal color) toward the inside. Be careful not to damage the sleeve of the pack seal.

pic 15

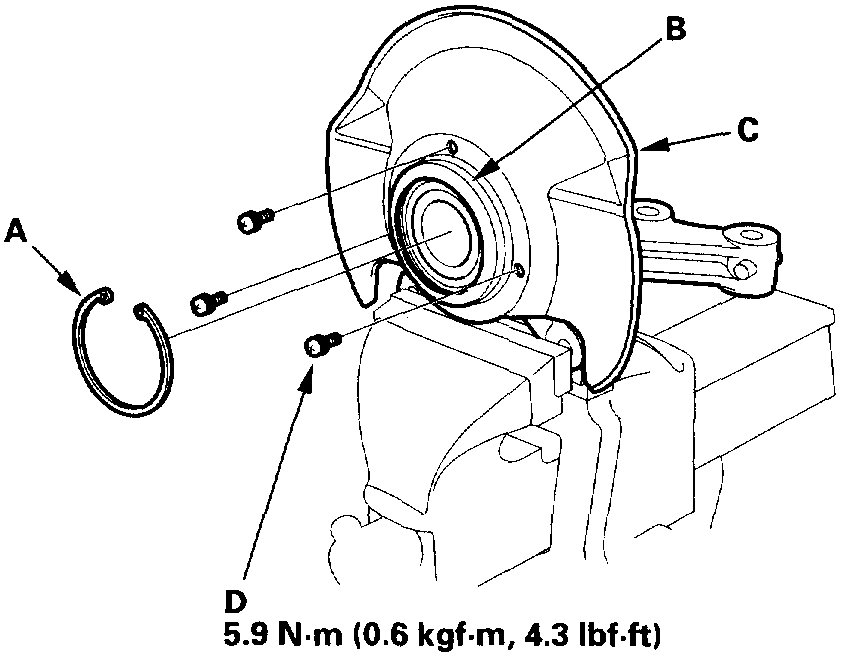

20. Install the snap ring (A) securely in the knuckle (B).

21. Install the splash guard (C), and tighten the screws (D) to the specified torque.

pic 16

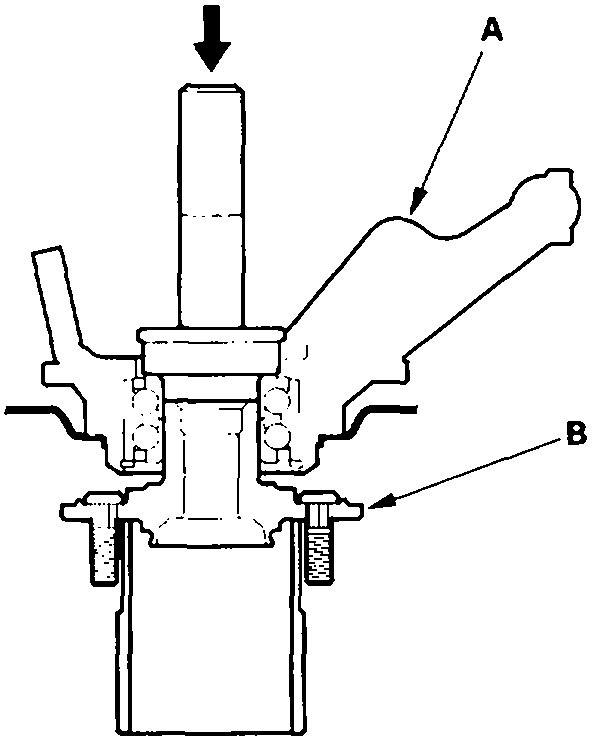

22. Press a new hub bearing unit (A) into the hub (B) using the special tools and a press.

23. Install the knuckle/hub/hub bearing unit in the reverse order of removal, and note these items:

- Be careful not to damage the ball joint boot when installing the knuckle.

- Tighten all mounting hardware to the specified torque values.

- Torque the castle nut to the lower torque specification, then tighten it only far enough to align the slot with the ball joint pin hole. Do not align the castle nut by loosening it.

- Install a new lock pin on the castle nut after torquing.

- Use a new spindle nut on reassembly.

- Before installing the new spindle nut, apply a small amount of engine oil to the seating surface of the nut. After tightening, use a drift to stake the spindle nut shoulder against the driveshaft.

- Before installing the brake disc, clean the mating surface of the front hub and the inside of the brake disc.

- Before installing the wheel, clean the mating surface of the brake disc and the inside of the wheel.

- Check the front wheel alignment, and adjust it if necessary.

___________________________

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Monday, April 29th, 2019 AT 6:54 PM