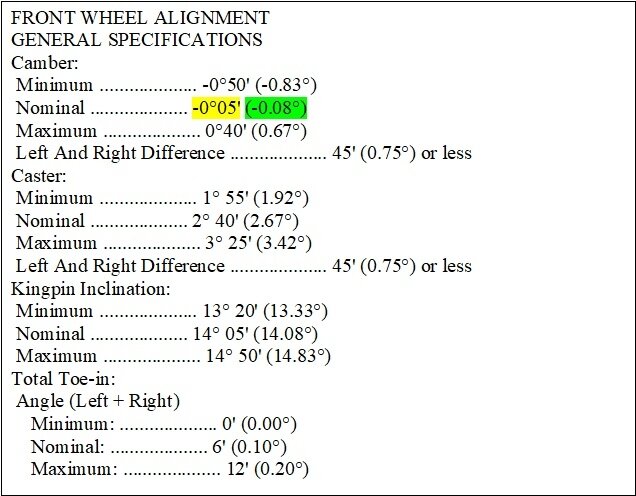

While it's surprisingly not as common as you'd think, 0.00 degrees, perfectly straight up and down, is not a real common spec for front camber. Most of the time we want just a fuzz of positive camber, but here, given the wide range of tolerance, I would aim for 0.00 degrees on the left front wheel, and that minus 0.08 degrees they call for on the right wheel. That would give me a 0.08 degree pull to the left to offset road crown. I found if I could sneak up to exactly 0.06 degrees pull to the left on all Chrysler front-wheel-drive models, I would not have a customer come back with a complaint of pulling either way. Most GM front-wheel-drive models were more tolerant, and wouldn't pull either way with a larger difference, within reason. With Fords, most of their models couldn't be bothered to even provide camber adjustments, so you just took what you got and let the owners put up with the pulling.

The tolerance for camber for your model allows for it to be as low as minus 0.83 degrees. That means as low as that, the value will still be in green on my computer, meaning it's "in specs". To the average car owner, they would think that's good, but I couldn't let a car go like that in good conscience. My computer has a button that can be pressed only once during an alignment to "Reduce tolerances". When I do that, the acceptable range that shows up in green tightens up to somewhere around -0.08 plus or minus 0.25 degrees. That just means I have to set it much closer to perfect before that number will turn green. That means more work for me, more time spent on that alignment, fewer jobs completed that day, but a happy customer. I left that dealership with a reputation of being one of the slowest mechanics in the shop, but the one with by far the fewest "comebacks". I never once in ten years got hollered at for working too slowly. By the way, comebacks'get worked on a second or third time at no additional charge to the car owner, and no pay for the mechanic, so shoddy workmanship has its own checks and balances.

As far as, "will one bolt be enough", it depends on how far it will increase camber. If it means it can raise camber 1 3/4 degree from where it is now, I guess I'd be happy with that. On the other hand, that more likely means it provides a 1 3/4 degree range, meaning it might only raise camber up one degree, and lower it 3/4 degree, from where it is now. Part of that 1 3/4 degree range might lower camber from where it is now. Chrysler's cam bolts provided well over a 3.00 degree range from lowest to highest, but there was also some play in there. If turning the cam bolt didn't bring camber up high enough, I could also pull out on the top of the tire to get some more, then hold the tire there with one hand, and my foot pushing in on the bottom, while I reached behind it to feel for the bolt head and socket with my second hand, and turn the ratchet with my other hand. Fortunately I didn't have to use all three hands very often. (There's other ways around that which don't require using three hands), but that doesn't humorize the story.

What I would suggest is to use the magnetic angle finder on the brake rotor and adjust it to read "0" so it's easy to remember your starting point. From here on, don't raise or lower the car or shift anything that will change that reading. Now remove the top bolt and install the new cam bolt in its place. There should be some play, but if you rotate it, it should only turn a little before it gets tight. Now loosen the lower bolt to remove the clamping force. Rotate the cam bolt some more and see if the brake rotor tips out on top. If you rotate the cam bolt far enough, it's going to start to bring camber back down. Keep rotating it until camber comes up as much as possible. If you can see anything close to a 2.00 degree increase, I'd call it good and head back to the alignment shop. If you can only get an additional degree or less, use the second cam bolt in the lower hole.

While unlikely, if you can't get close to enough camber increase with two cam bolts, I'd pursue grinding one or both holes in the strut, and forget about the cam bolts. Remember, those are just an aid to make it easier to make the adjustments during the alignment. After that, they just need to provide the clamping force, and the original bolts can still do that.

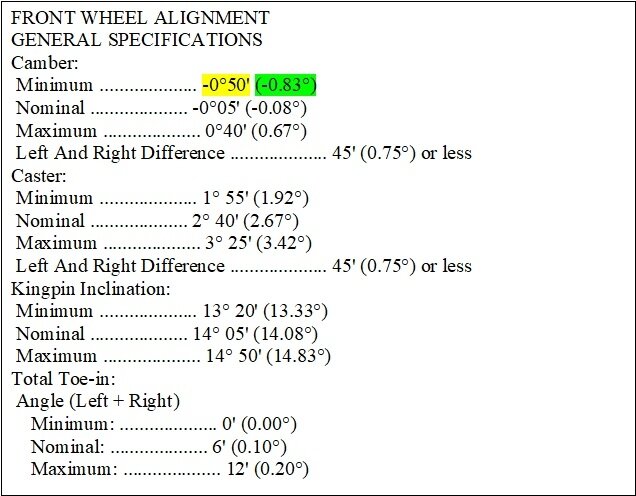

Made a booboo with what I highlighted, but I can't delete the first image. Pretend it's not there and just look at the second one.

Was this helpful?

Yes

No

+1

Saturday, June 3rd, 2023 AT 7:57 PM