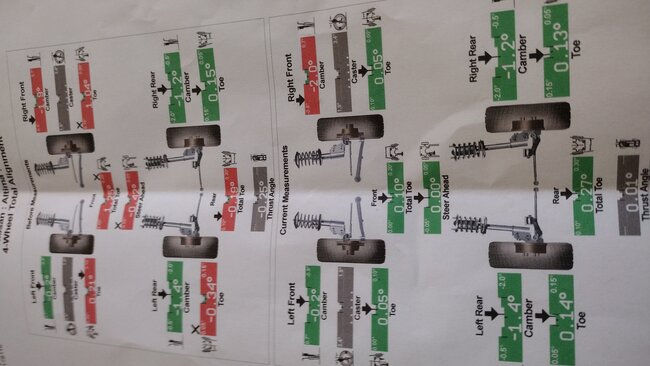

This job is actually less expensive than you might think, and it's very common.

First of all, find out if that one-year warranty, which is already better than you normally get, covers only mistakes made by the tech, or if it will include a realignment after doing the strut work. If you come in with new struts, or even other parts, they could say the resulting need for another alignment isn't their fault, so you have to pay again. Usually the concern is this type of adjustment method can slip when you hit big pot holes. That's the type of thing they typically want to take care of for you.

As for the struts, there's three ways to approach this. One way is to replace both front struts. That includes a significant safety concern with flying coil springs. I've seen two shoot out of the compressor. One took out an 8-foot overhead light fixture. The one that happened to me shot all the way across the shop, out the door, and through the parking lot. It made so much noise, the office manager who was sitting behind two closed doors ran out to see what had happened. Now we all use wall-mounted compressors, but do-it-yourselfers don't have access to those unless you have a friend who is a mechanic. The safety issue is with the portable compressors, especially those referred to as "clamshell" compressors.

I can walk you through the job. You can most likely borrow a strut compressor from an auto parts store that rents or borrows tools. In my city, they make you buy the tool, then you get a full refund when you take it back. If you choose to keep a tool, you still take it back, then they give or order you a brand new one.

Once you remove the assembly, the spring only needs to be compressed less than an inch to remove the force on the upper mount. That upper mount has a rubber insert in it that can deteriorate, but you can't see that until after it is taken apart. If you need to order new ones, the car has to sit until they arrive, or you have to put it all back together, then start all over days later. I've had to do that more than once with customer cars. Same is true if there is a rubber "isolator" between the bottom of the spring and the metal plate it sits on. Chrysler used those to reduce the transmission of road noise, but here again, you can't really tell if they're worn until everything is taken apart. The new struts can be installed without those parts, but it lowers the front end by about 1/2". My parts department never stocked them because they showed no sales history for them. I pointed out there was no sales history because for years the previous tech was leaving out the worn ones rather than leaving that car torn apart on his hoist for days. Once they began keeping a pair in stock, I was using them on about one in ten strut jobs. Made for lots of customer satisfaction at very low cost. Be aware most car brands don't use those isolators, so this isn't an issue.

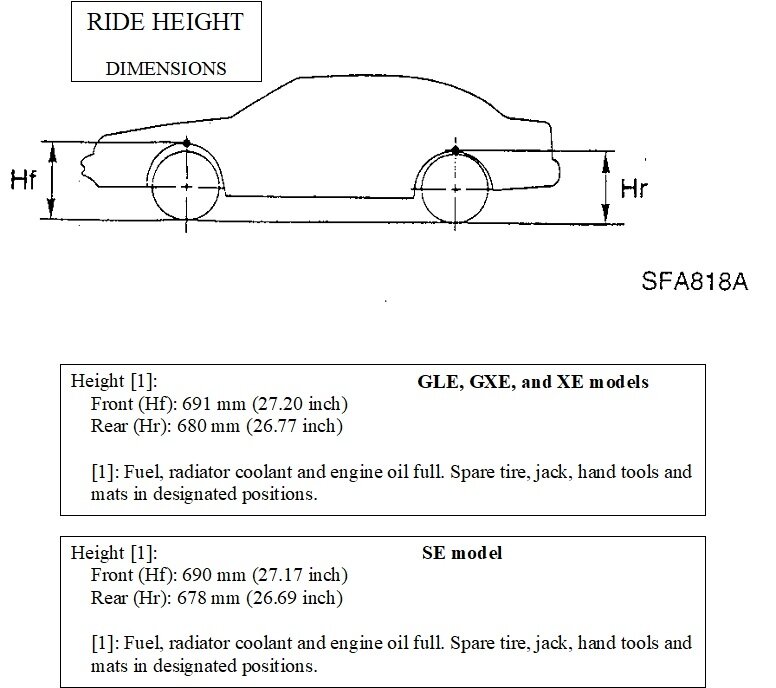

Before you go that route, measure the front ride height. The drawing shows to take them at the top of the wheel openings. This method does not account for non-standard tire sizes, so you have to make allowances for that. If you find one side is lower than the other, or if both sides are significantly lower than specs, the better value is to install a pair of "quick struts". Those are the struts, coil springs, upper mounts, dust boots, and those isolators if they are used, all in one package already assembled and ready to install. This restores ride height to specs, and you don't have to worry about the condition of the upper mounts or the safety concern of a spring popping out of the compressor. When you pay me to do this job, you save much more in labor time than the small higher cost over just the bare struts. I compare installing new bare struts with old, used springs and mounts to buying new shoes, but using old, ragged shoelaces to hold them to your feet.

Even with either new bare struts or quick strut assemblies, you can't be sure one of the mounting holes will come elongated. As I mentioned, those on Chrysler and Chrysler replacement struts are always oval-shaped, and original GM ones are always not. The holes in aftermarket replacement GM struts usually are, but if not, you have to grind them out. That job only needs to be done once to make them adjustable.

I think you're in for unnecessary misery if you try to drill the holes out. I could be wrong, as I never tried it that way, but the easier way is with a die grinder and metal-cutting bit. You can find them in electric models, but all I've ever used are air-powered. You can find them at Harbor Freight Tools, Walmart, or any hardware store. Be sure to wear safety glasses, and I recommend wearing disposable rubber gloves. I never wore the gloves, and always ended up with a few tiny metal slivers in my hands.

On Chryslers and GMs, the lower of the two holes gets elongated. I've had some import models where the adjustment can't be made that way due to the spindle bumping into the bottom of the strut body. I suspect that's why they show grinding the upper hole for your car. The way to see what's taking place is to raise the front end off the ground, support it with jack stands under the frame, not the lower control arms, remove the wheel and tire, then remove the upper bolt, and finally, loosen the lower bolt. If things are rusted tight, you may need to loosen that lower nut a good full turn, then hit it with a hammer to push the head back a little to release the clamping force. Since the suspension is hanging freely, there won't be a lot of pressure on that lower bolt.

Now grab the bottom of the strut and pull it out toward you. Doing so makes the strut tilt in on top more than before, but it makes the spindle tip out on top, which is what we're after. As an educated guess, I'd say you want the top of the brake rotor to move outward roughly 1/4" Don't waste your time trying to measure that. It's just an estimate to get you in the ballpark. Once you pull it out that much, snug the lower bolt. If it wants to pop back in or out on its own, lightly snug the bolt first, leaving it just loose enough that you can pry it out a little, then tighten the bolt more to keep it there.

At this point you're going to find the upper holes are no longer lined up with the hole through the spindle and you can't get the bolt in. This is where you have to grind the holes on both sides of the strut until the bolt will go in. With a new, sharp cutting bit, that can be done in as little as a couple of minutes, or it can take longer, depending on how far you have to cut. You only need to cut the holes as much as is needed to get the adjustment you need. That's impossible to know by eye, so a good recommendation is to grind the holes 3/16" larger. That should be more than enough to get 2.0 degrees more camber.

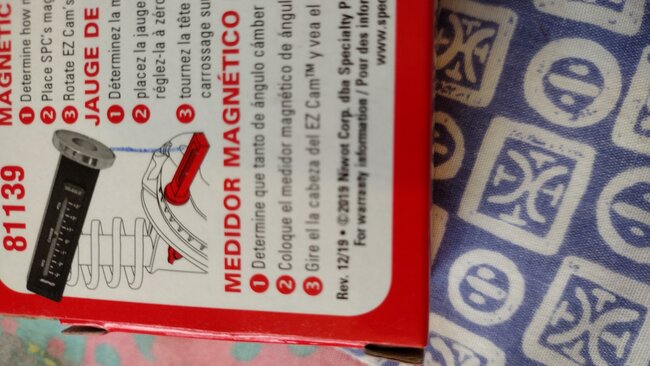

As an alternative, if you look on the Rock Auto site, under "Suspension" for your model, they show two different styles of special bolts at the top of the list of parts. I'm not familiar with using either one, so hopefully they come with instructions. I still prefer grinding the holes.

Oh. Yeah; don't get excited if the cutting tool suddenly starts flying around in the hole. Hold it tightly and vary the speed to help prevent that. It's one of the few miserable parts of the procedure.

You can use a little grease on the bolt threads if you want to, but don't put anything on the spindle where it mates with the strut, especially no anti-seize compound. A coworker thought he was doing me a favor when he replaced some struts, but that left them with absolutely no clamping force. The adjustments kept slipping every time I set the car back down on the hoist. Eventually I got so frustrated, I tightened and tightened the first bolt so much that I pulled it apart with a hand ratchet. That bolt was over 5/8" in diameter, and I snapped it with hand tools. That's when I had to take everything apart and found that anti-seize compound. Better to just leave everything dry.

The last thing, once everything is reassembled using the same struts, is to observe that up to now, the two front toe readings are good, and the steering wheel is straight. That won't be the case once the wheel is fixed. This next comment isn't too important, but if you look at how far the lower ball joint is off the ground, then look at how far the stud for the outer tie rod is off the ground, most likely you'll see they aren't the same. If they are, this last comment has less value, but on most cars, the tie rod end is a good two to six inches higher. The reason this observation has value is when you tip the wheel out, the lower ball joint stays in place, but the steering arm on the spindle moves out, along with the top of the spindle / bottom of the strut. The attaching point of the tie rod end moved out, but the tie rod didn't. If the steering linkage is in back of the half shaft, as most are, this causes that wheel to turn to the right when you tip it out. How much it turns can be pretty significant, enough in fact to cause tire squealing as you drive back to the alignment shop. Because we know you're starting with a straight steering wheel, here's an easy trick to get that right front toe back close to where it should be.

Because this procedure made the right front wheel turn to the right, you have to turn the steering wheel to the left to kind of get the car to go straight. Before you put everything back together to prove that to yourself, adjust the tie rod's linkage longer. The jamb nut is normal thread. The nut is typically an 18 to 21mm, and if you can get straight on it, you may be able to loosen it with one hand on the wrench. Once it's loose, rotate the inner tie rod end to back it out of the outer one. There's usually a six-sided area made to fit an open-end wrench, but we just use a large pair of pliers. As you rotate that, you'll see the brake rotor turning to the left. A good guess is to lengthen that link by about 1/8" as a starting point. That should be enough to make the car drivable.

Now for the fun part. Once everything is reassembled, go out and drive the car and see where the steering wheel is. If it's still to the left, that linkage needs to be extended a little more. I would often take a wrench with me on test drives, then park on the side of the road to make this adjustment to get it close while waiting my turn on the alignment rack. When you get it to where the steering wheel is nearly straight, you'll know toe is back where it was right after the alignment.

To add unnecessary confusion, another way to look at this, is when the steering wheel is off-center to the left, the wheels are supposed to be too to match that, but right now, they aren't. You have to adjust toe to put the wheels where they match the steering wheel, and that means turning something to the left. Since we know the left wheel was correct and it hasn't been touched, it can only be the right wheel that needs to be adjusted. This only works when one strut is replaced or modified. If you replace both struts, this still works if you do one at a time. Adjust toe on that wheel to get the straight steering wheel back, then go to work on the second side and do it the same way. This still only gets you close. An alignment is still needed. Toe can go in or out of specs with as little as 1/8 turn on the inner tie rod end, but you'll never see that change in the steering wheel. It will show up later in the tire wear patterns.

Don't leave the jamb nut loose, but you don't have to over-tighten it either. With being loose, the inner and outer tie rod ends will hammer against each other and wear away the threads. They'll get loosened and retightened during the realignment, so your goal here is to just get everything close.

The only thing that can lead to disappointment is if you find out you didn't grind the holes big enough to get the full 2.0 degrees needed. By recommending 3/16", I think that should be enough, but there's no harm in going a little bigger to be on the safe side.

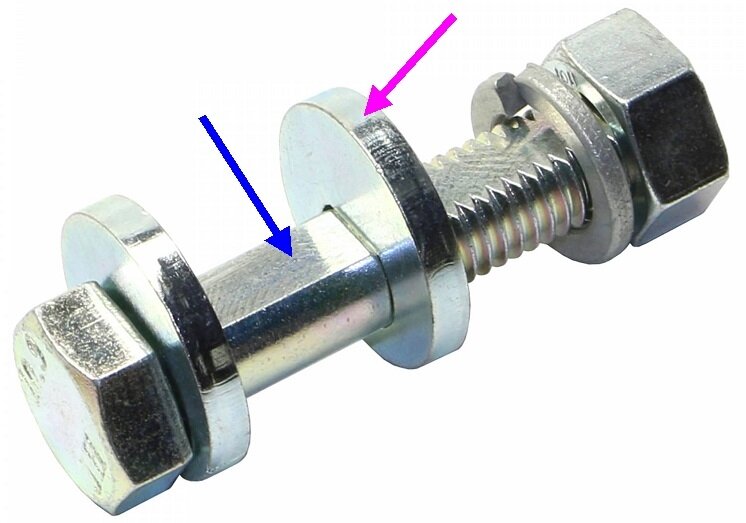

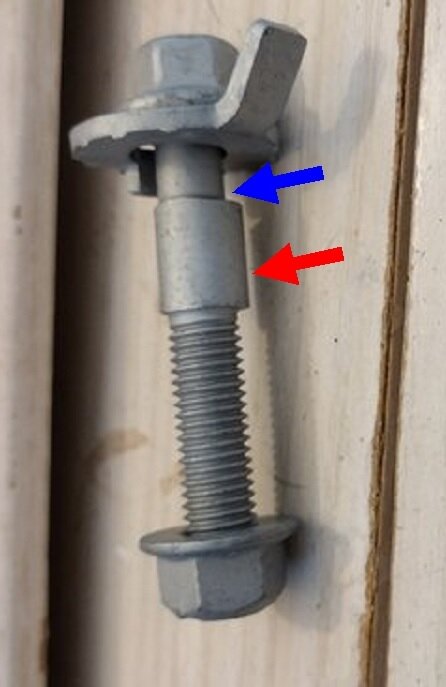

The second photo shows a front strut from a Caravan The third photo shows an aftermarket replacement for a Chevy Cavalier. On both of these, the lower holes is elongated, and if you look right above it, you'll see a raised area that looks like a bump. Also, notice the lip on the bottom corner. Both are easier to see in the Chevy photo. That lip and bump form a pocket for an eccentric bolt to fit in. That's the bolt I mentioned with the offset head. As the bolt is rotated, that head is forced to sit in that pocket, so the shaft of the bolt moves back and forth. That pushes or pulls on the hole in the spindle to force it to move. Better yet, since it can't rotate or move once it is tightened, it really holds it in place well when driving over bumpy roads. Most Chrysler models come with those cam bolts. They have to be added on GM alignments, at extra cost, but only the first time they're needed. A lot of shops don't stock those bolts, so they just rely on the original ones to hold everything in place. That can be acceptable for your car too.

The only thing I didn't discuss yet is removing the large nut at the top of the strut's shaft.

Don't do that before the spring is compressed. Each spring holds up over 1,000 pounds of car, so there's that much pressure on it as it is removed from the car. To remove the nut that way would send the upper mount airborne. It most likely would not take out an airplane, but it will do serious damage to heads. This step is avoided when installing quick struts.

On most struts, as shown on these two, but hard to see, there's a hex on top to hold the shaft from spinning while the nut is backed off with another wrench. That's fine when doing this once, but it takes way too much time for a professional. The way I get them off is to use a 1/2" air impact wrench, but I pulse the trigger repeatedly. To hold it steady will just spin the shaft endlessly and make it dizzy. By pulsing it, the shock backs the nut off a little each time I run them on the same way, but with new struts it's a good idea to do that rather slowly. The shaft spins a little each time, and spinning too much too fast can overheat and melt the rubber o-ring seal at the top of the strut body. Those are lock nuts, so they won't just spin on by hand. You'll need the impact wrench or two hand wrenches.

Once that nut is tight, the last step is to loosen the spring compressor. As you do that, observe the bottom end of the spring must be rotated to meet the raised section of the metal mounting plate. That's called "indexing" it. Any time you're reinstalling used struts, wipe off any dirt on that plate. That, and small pebbles that get caught in there can cause a crunching noise. Also note the top end of the spring indexes with a mating formed area under the upper mounting plate. That upper plate is in two parts with a bearing in between. That's to allow the strut to rotate with the steering system while holding up all that weight. It's not uncommon to find the three bolts on top don't line up with the three holes in the inner fender. Normal procedure is to lift the assembly up and insert the three bolts first, loosely install the nuts to keep it there, then rotate the strut by hand to line up the bottom with the spindle. You may have to grunt with both hands, but some struts turn rather easily.

Many models also have brake hose brackets ad anti-lock wheel speed sensor wires attached to the struts. Don't forget to reinstall them.

Images (Click to make bigger)

Wednesday, May 31st, 2023 AT 8:52 PM