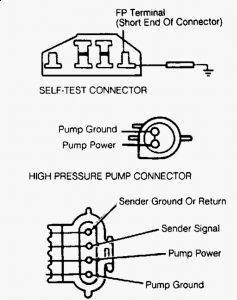

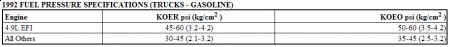

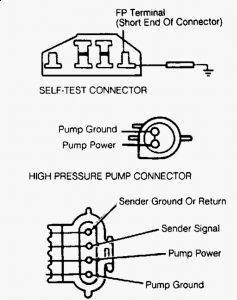

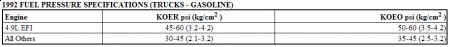

FUEL DELIVERY Fuel Pump Relay See MODULES, MOTORS, RELAYS & SOLENOIDS. Fuel Pump Testing 1. Visually inspect entire fuel delivery system for leaks, damaged or kinked lines and hoses. Ensure battery is fully charged and fuses are okay. Ensure adequate fuel is available in fuel tank. Release fuel pressure. See FUEL SYSTEM PRESSURE RELEASE . Install fuel pressure gauge. With Key On Engine Off (KOEO) to activate pump, check and record fuel pressure. For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. Proceed to appropriate step, as indicated: � � � If fuel pressure is within specification, go to step 2). � � � If fuel pressure is zero, go to step 5). � � � If fuel pressure is low, go to step 11). � � � If fuel pressure is high, go to step 12). 2. Check fuel injectors. See FUEL CONTROL. Crank or run engine. Using a mechanic's stethoscope, listen for regularly spaced operating sounds at each injector. If sound is present, check fuel injectors for flow and leakage. Clean or replace injectors as necessary. 3. If injector operating sound is not present, check fuel injector resistance. See FUEL CONTROL. If injector is not within specification, replace as necessary. If injector is within specification, check injector electrical connections for continuity to ECA. If no continuity exists in circuit, check for 12 volts at each injector lead. 4. If voltage is not present at injector, see Quick Test procedure in TESTS W/CODES article in the ENGINE PERFORMANCE Section. Faults in injector circuit should set a service code. If no service code has been set, see CIRCUIT TEST H in TESTS W/CODES article in the ENGINE PERFORMANCE Section. 5. If fuel pressure is zero, ensure battery is fully charged and key is off. Ground fuel pump lead. Using a jumper lead, ground FP terminal at SELF-TEST connector. See Fig. 8 . Ensure connection is okay at pump/sender unit. Turn ignition on, engine off. Listen for sound of fuel pump running. If pump is running, proceed to next step. If fuel pump is not running, proceed to step 7). Fig. 8: Identifying Fuel Pump & Self-Test Connectors Courtesy of FORD MOTOR CO. 6. Check condition of high-pressure fuel filter. If filter is free of contamination check fuel NOTE: For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article. NOTE: For fuel system pressure testing and fuel pressure specifications, see BASIC TESTING article in the ENGINE PERFORMANCE Section.

pressure regulator, go to step 12). If filter is contaminated, replace filter and recheck system pressure as outlined in step 1). 7. Turn ignition off and disconnect fuel pump/sender or high pressure pump connector. Set DVOM on 200-ohm scale. Measure resistance between pump ground at connector and chassis ground. If resistance is one ohm or more, repair open circuit to ground. If resistance is less than one ohm, go to next step. 8. Ensure ignition is off and battery is fully charged. Disconnect harness connector from pump/sender unit. Ground FP terminal at SELF-TEST connector. With KOEO and DVOM on 20-volt scale, measure voltage at Pump Power terminal of pump/sender or high pressure pump connector. If voltage is 10.5 volts or more, replace pump/sender assembly. If voltage is not as specified, go to next step. 9. With KOEO, check voltage at fuel pump inertia switch. If voltage is 10.5 volts or more at both inertia switch terminals, repair wire between inertia switch and pump. If voltage is not as specified, reset or replace inertia switch as necessary and go to next step. 10. Ensure ignition is off and battery is fully charged. Ground FP terminal at SELF-TEST connector. With KOEO and DVOM on 20-volt scale, measure voltage at fuel pump relay (Brown wire). If voltage is 10.5 volts or more at relay, repair Brown wire between fuel pump relay and inertia switch. If voltage is not as specified, check voltage supply to fuel pump relay and to terminal No. 1 at ECA. For additional circuit testing information see CIRCUIT TEST J in TESTS W/CODES article in the ENGINE PERFORMANCE Section. 11. Ground FP terminal at SELF-TEST connector. Using a DVOM, check voltage at fuel pump terminal (Pink/Black wire). If voltage at fuel pump is within .5 volt of battery voltage, go to step 6). If voltage is not as specified, go to step 5). 12. Check engine compartment vacuum hose for leaks and ensure engine produces normal engine vacuum. See appropriate FUEL PRESSURE REGULATOR test procedure. Fuel Pressure Regulator (Gasoline) 1. Ensure key is off. Connect fuel pressure gauge to Schrader valve on fuel rail. Ensure manifold vacuum supply tube is connected to fuel pressure regulator. Start and run engine for 10 seconds. Stop engine and wait 10 seconds. Start and operate engine for 10 seconds. Stop engine and remove pressure regulator vacuum hose. See Fig. 9 . Check vacuum port for fuel. Fig. 9: Identifying Fuel Pressure Regulator Components Courtesy of FORD MOTOR CO. 2. If fuel is present, replace fuel pressure regulator and repeat test. If fuel is not present, start and run engine for 30 seconds. Stop engine and check fuel pressure gauge. If fuel pressure does not drop, go to step 4). If fuel pressure drops more than 5 psi (.4 kg/cm 2 ) in 60 seconds, disconnect and plug fuel return line at engine. Cycle ignition key on and off until normal fuel pressure is obtained. 3. Turn key off and check fuel pressure gauge. If gauge drops more than 5 psi (.4 kg/cm 2 ) in 30 seconds, replace high pressure fuel pump (dual pump system) or fuel sender/pump assembly (single pump type). If gauge does not drop more than 5 psi (.4 kg/cm 2 ) in 30 seconds, replace CAUTION: Inspect fuel system for leaks or damage before testing fuel pump.

fuel pressure regulator. 4. Ensure key is off. Relieve fuel pressure. Remove fuel pressure regulator. Check "O" ring, gasket and mounting surfaces for cracks, cuts or other damage. Connect vacuum pump to fuel return tube and apply 20 in. Hg. If maximum vacuum loss exceeds 10 in. Hg in 10 seconds, replace regulator. If maximum vacuum loss does not exceed 10 in. Hg in 10 seconds, recheck entire fuel delivery system for cause of fuel pressure loss.

Friday, August 28th, 2009 AT 9:04 PM