Hi and thanks for using 2CarPros.com.

Chances are a headgasket has failed. Take a look at this link for testing.

https://www.2carpros.com/articles/head-gasket-blown-test

As far as your other question regarding the engine block, to check for cracks, the only way I know how is to magnaflux. It requires the components to be checked to be removed from the car, clean. However, it would not work on aluminum, but instead a dye would be used.

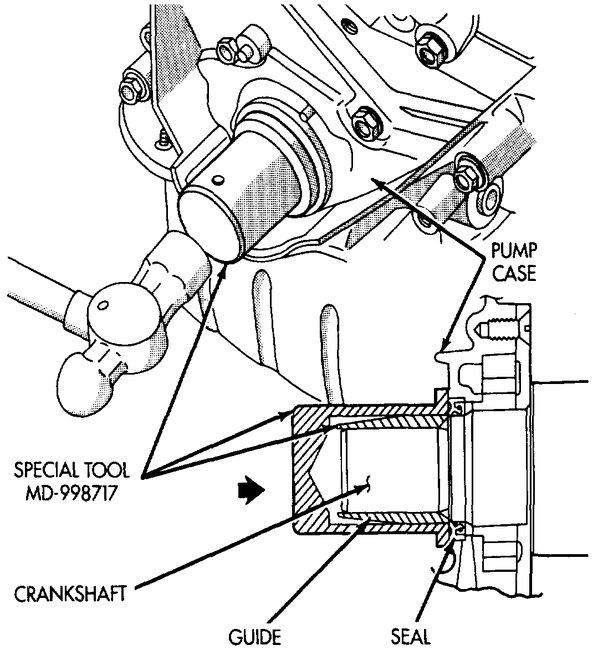

I wanted to add the following directions for you to review to make sure nothing went together wrong. It shows the torque specs also. Pictures 1 and 2 correlate with these directions.

______________________________________________

REMOVAL

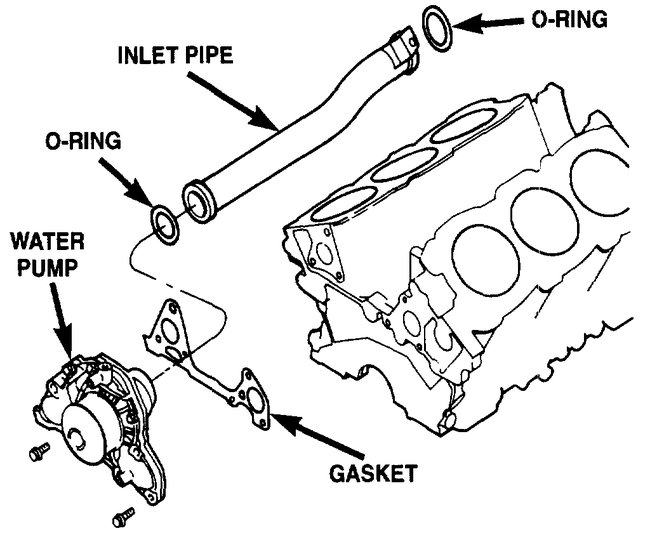

1. Drain cooling system.

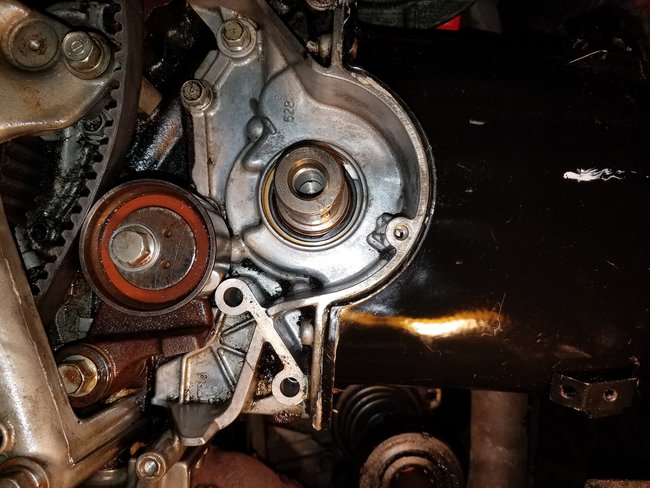

2. Remove timing belt and camshaft sprockets.

3. Remove upper intake manifold assembly.

4. Remove cylinder head covers and rocker arm assemblies.

5. Remove distributor.

6. Remove exhaust manifolds and cross under pipe.

7. Remove cylinder head bolts and remove cylinder head.

INSTALLATION

1. Clean surfaces of head and block. Install head gasket over locating dowels.

2. Install head on locating dowels.

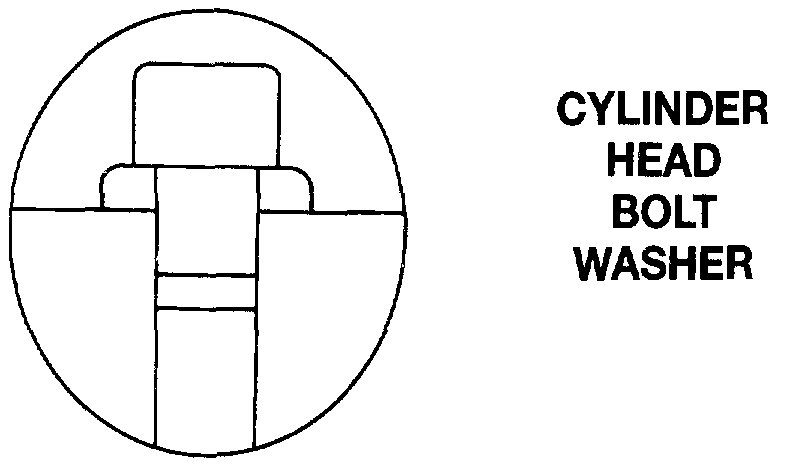

3. Install 10 mm Allen hex head bolts with washers.

Cylinder Head Bolt Washer

CAUTION: Attach the head bolt washer in the direction shown.

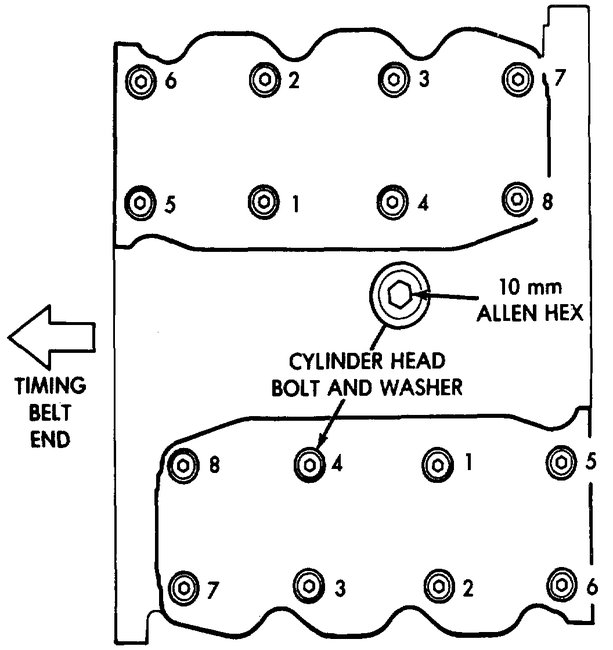

Cylinder Head Bolt Tightening Sequence

4. Tighten bolts in the order. When tightening the cylinder head bolts, tighten gradually, working in two or three steps and finally tighten to specified torque of 108 Nm (80 ft. lbs.).

____________________________

I also wanted to add that the type of head gaskets used changed in 1998. Pre 1998 a composite gasket was used. 1998 changed to a steel gasket to compensate for reduced clearance. One last thought, when preparing aluminum gasket surfaces for new gaskets, it is very easy to damage the surface. If you used a steel gasket cleaner, gasket grinding discs or the equal, the surface may have been damaged.

I hope this helps. Let me know if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Sunday, August 26th, 2018 AT 7:27 PM