This video shows the job being done on a similar car but the process is the same with instructions in the diagrams below to show you how on your car.

https://youtu.be/JpzefqEeVGE RWD

https://youtu.be/6N6b5F2ChyE FWD

Here is a guide to help you step by step with instructions in the diagrams below to show you how on your car.

https://www.2carpros.com/articles/how-to-replace-a-clutch

This video can tell you if you have a bad clutch

https://youtu.be/EpBMj5ZY_bo

Check out the diagrams (Below). Let us know what happens and please upload pictures or videos of the problem.

It needs a new clutch. It's slipping. The putting it in 5th and letting out the clutch test was a good one. I thought I was the only one that did that to test. LOL

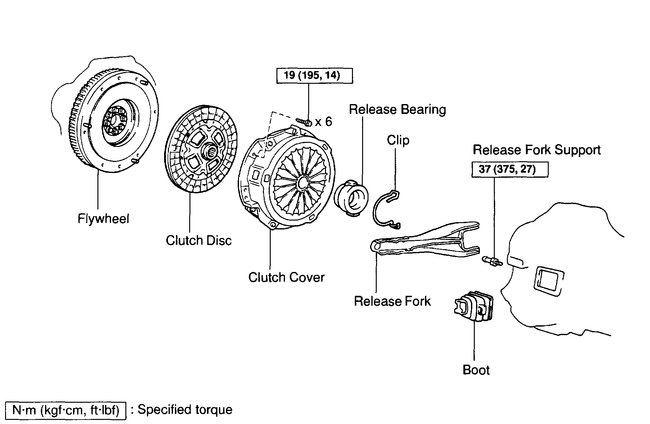

Here are directions for checking and replacing everything. In this case, I would suggest replacing the clutch disc, pressure plate, release bearing, and having the flywheel resurfaced. Here are the directions. The attached pictures correlate with the directions.

Check out the diagrams (Below). Please let us know what happens.

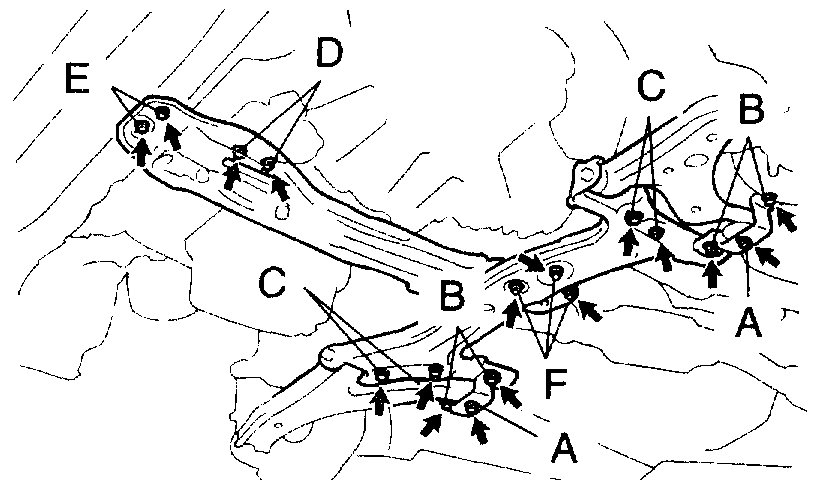

REMOVAL

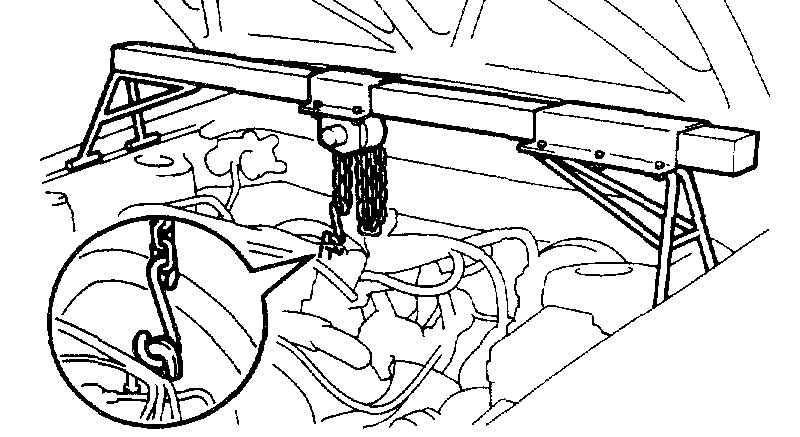

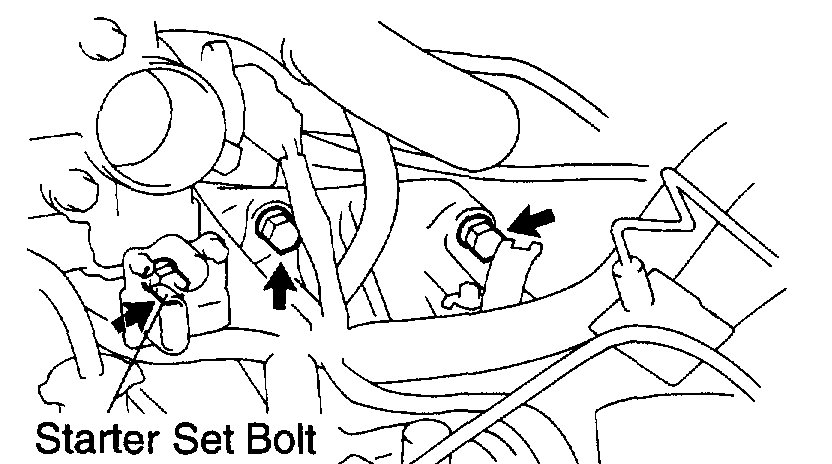

1. REMOVE TRANSAXLE FROM ENGINE

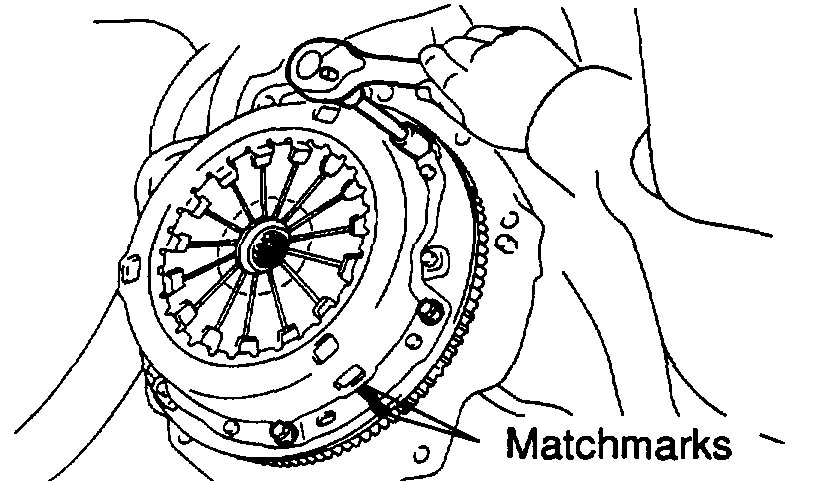

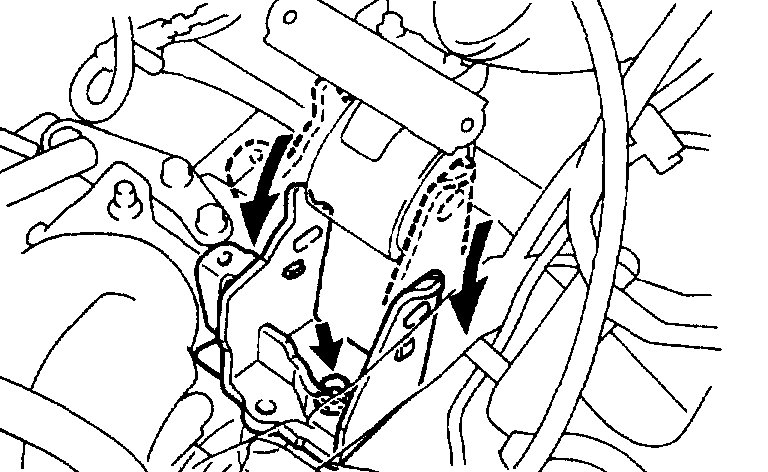

2. REMOVE CLUTCH COVER AND DISC

a. Align the matchmark on the clutch cover with the one on the flywheel.

b. Loosen each set bolt one turn at a time until spring tension is released.

c. Remove the set bolts, and pull off the clutch cover with the clutch disc.

NOTICE: Do not drop the clutch disc.

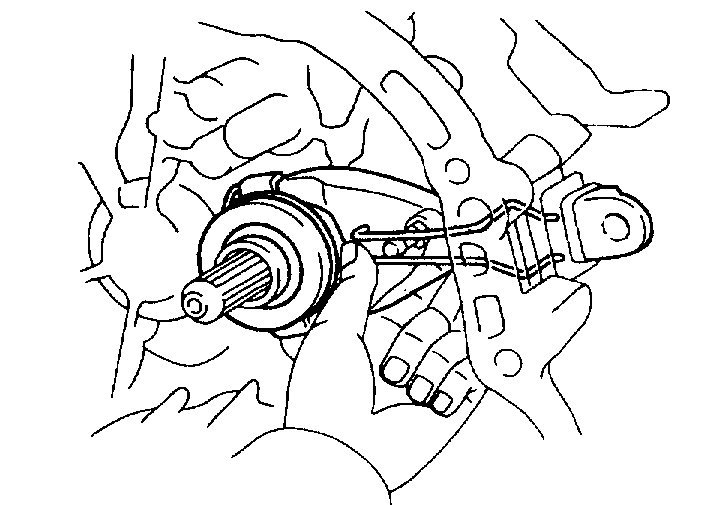

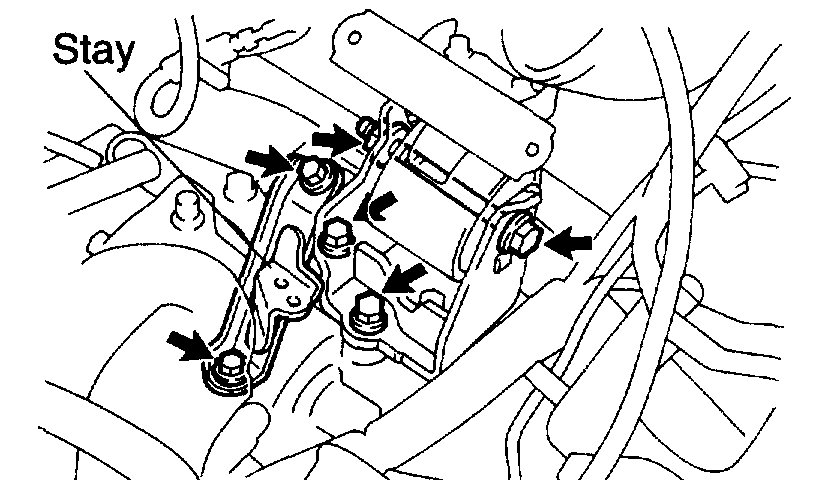

3. REMOVE RELEASE BEARING AND FORK FROM TRANSAXLE

Remove the release bearing with the fork together and then separate them.

4. REMOVE RELEASE FORK SUPPORT AND BOOT

INSPECTION

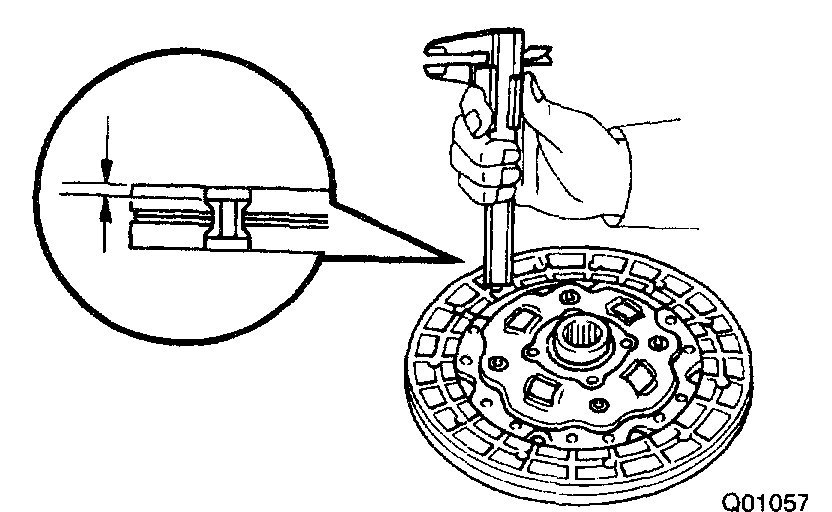

1. INSPECT CLUTCH DISC FOR WEAR OR DAMAGE

Using calipers, measure the rivet head depth.

Minimum rivet depth: 0.3 mm (0.012 inch)

If necessary, replace the clutch disc.

Inspect Clutch Disc Runout

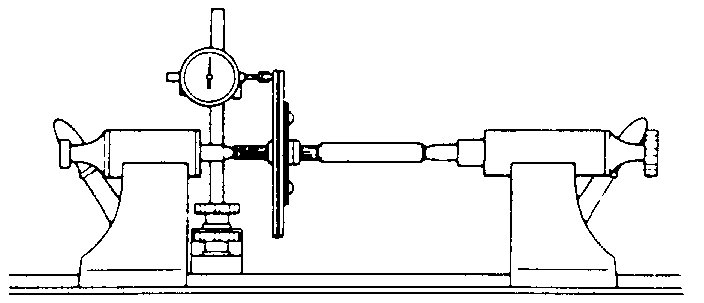

2. INSPECT CLUTCH DISC RUNOUT

Using a dial indicator, check the disc runout.

Maximum runout: 0.8 mm (0.031 inch)

If necessary, replace the clutch disc runout.

3. INSPECT FLYWHEEL RUNOUT

Using a dial indicator, check the flywheel runout.

Maximum runout: 0.1 mm (0.004 inch)

If necessary, replace the flywheel.

Torque: 49 Nm (500 kgf-cm, 36 ft. lbs.)

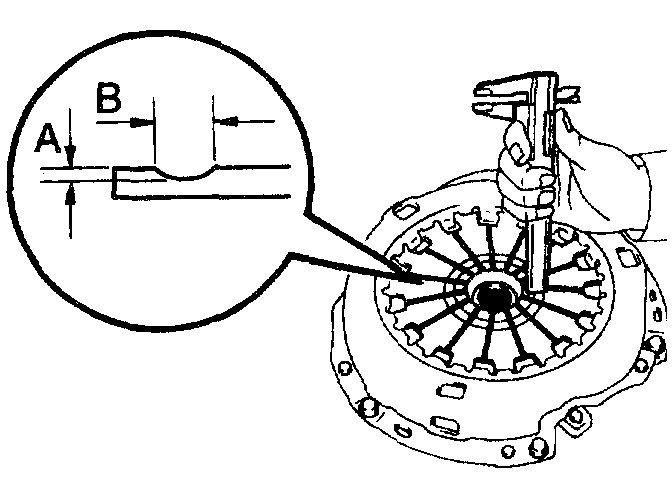

4. INSPECT DIAPHRAGM SPRING FOR WEAR

Using calipers, measure the diaphragm spring for depth and width of wear.

Maximum:

A (Depth): 0.5 mm (0.020 inch)

B (Width): 6.0 mm (0.236 inch)

If necessary, replace the clutch cover.

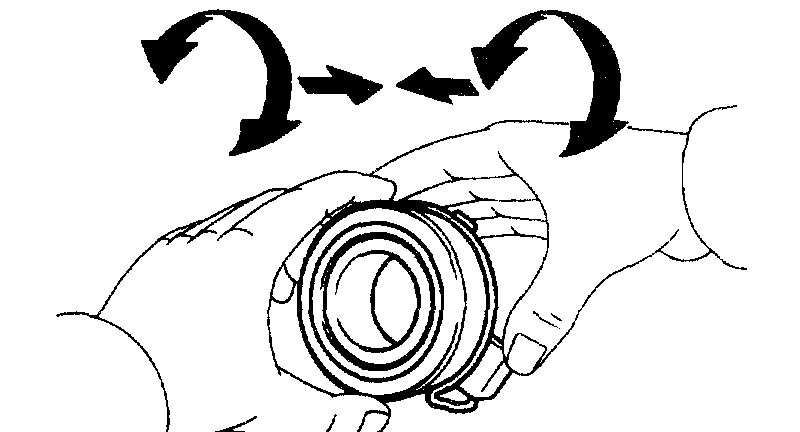

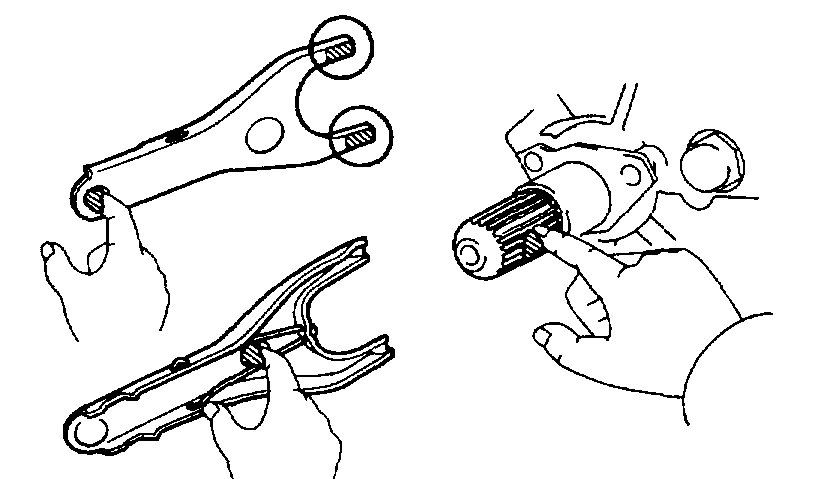

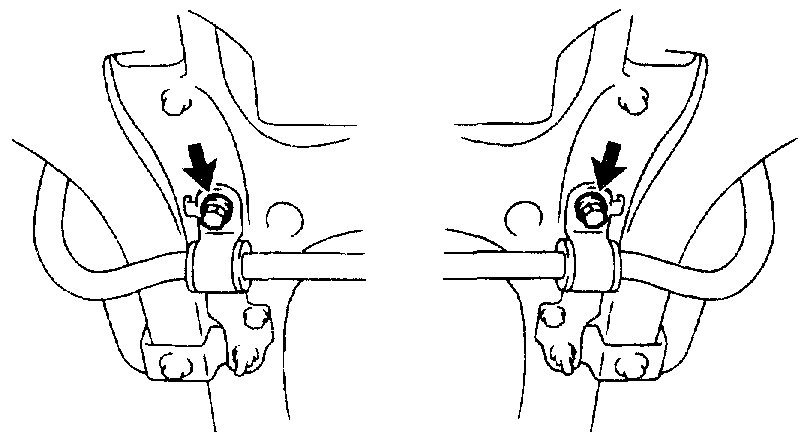

5. INSPECT RELEASE BEARING

Turn the bearing by hand while applying force in the axial direction.

HINT: The bearing is permanently lubricated and requires no cleaning or lubrication.

If necessary, replace the release bearing.

INSTALLATION

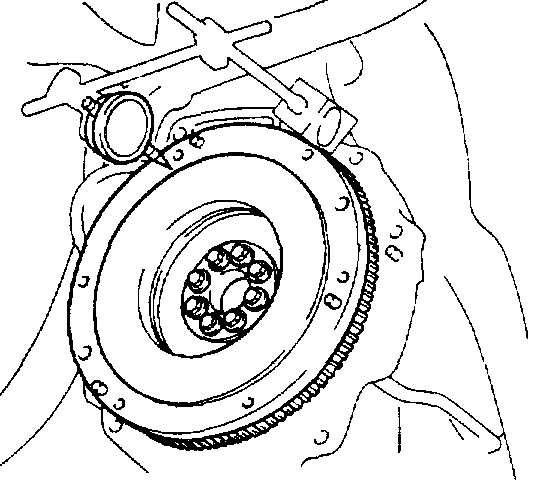

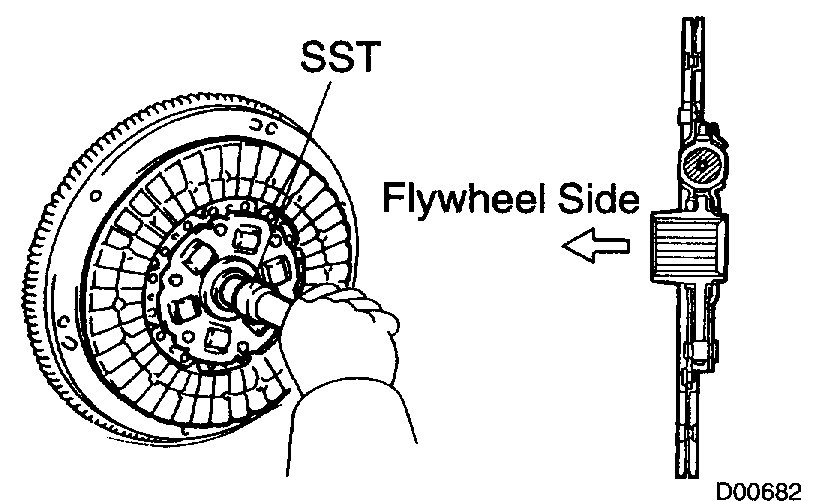

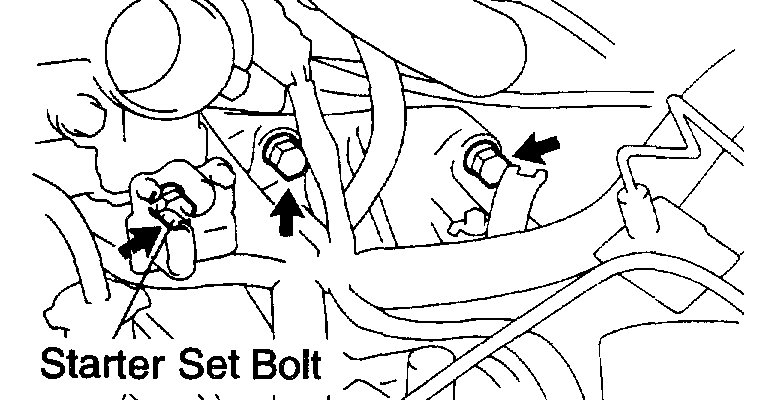

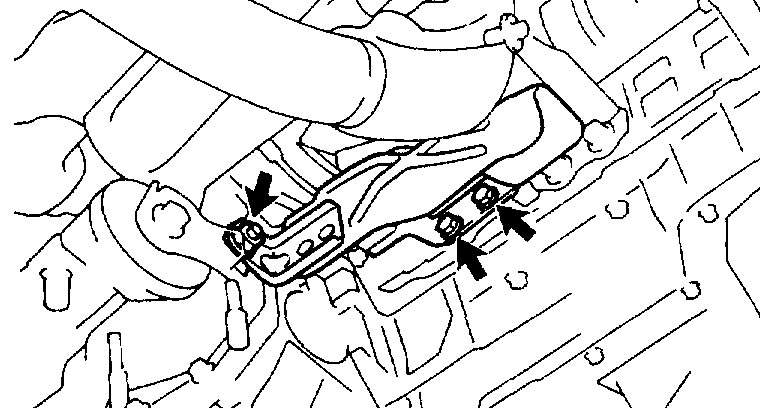

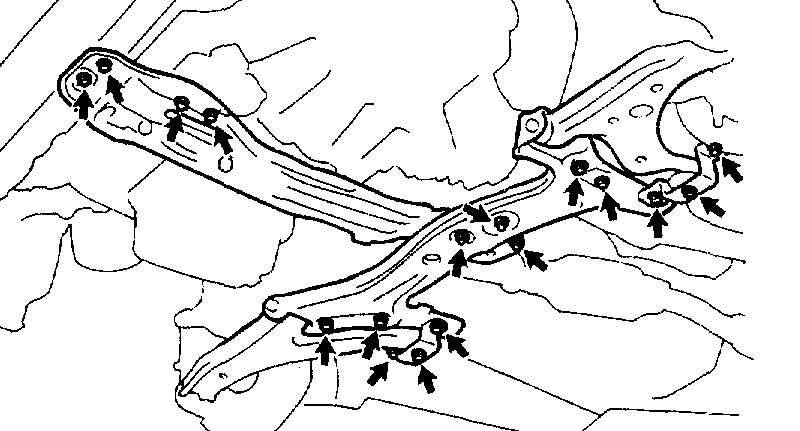

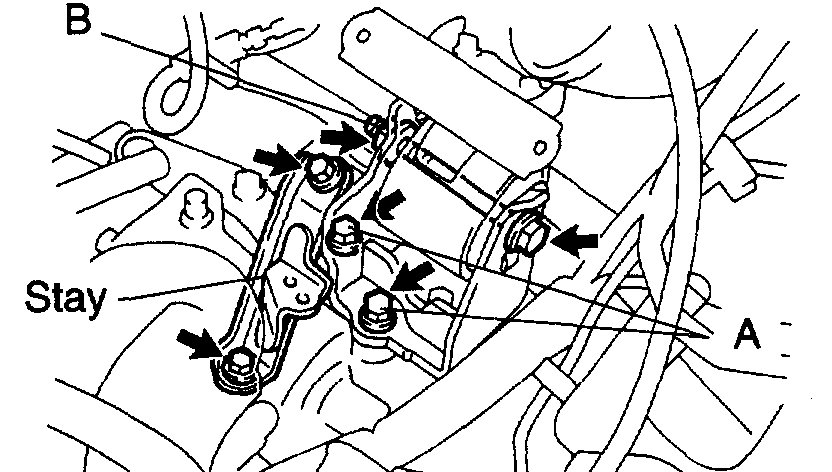

1. INSTALL CLUTCH DISC AND CLUTCH COVER ON FLYWHEEL

a. Insert SST in the clutch disc, then insert them in the flywheel.

SST 09301-00210

HINT: Take care not to insert clutch disc in the wrong direction.

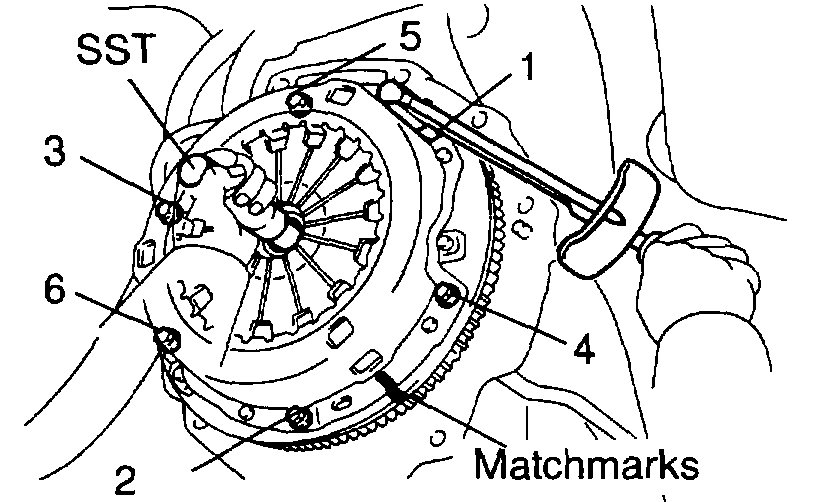

b. Align the matchmarks on the clutch cover and flywheel.

c. Following the procedures shown in the illustration, tighten the 6 bolts in the order starting the bolt locating near the knock pin on the top.

Torque: 19 Nm (195 kgf-cm, 14 ft. lbs.)

HINT:

Following the order in the illustration, tighten the bolts at a time evenly.

Move SST up and down, right and left lightly, after checking that the disc is in the center, tighten the bolts.

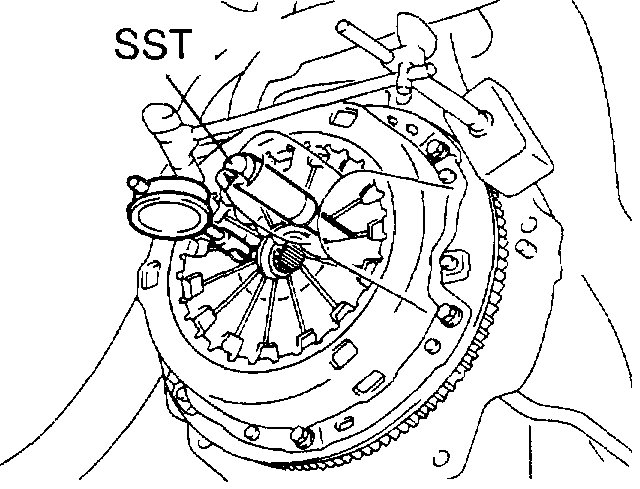

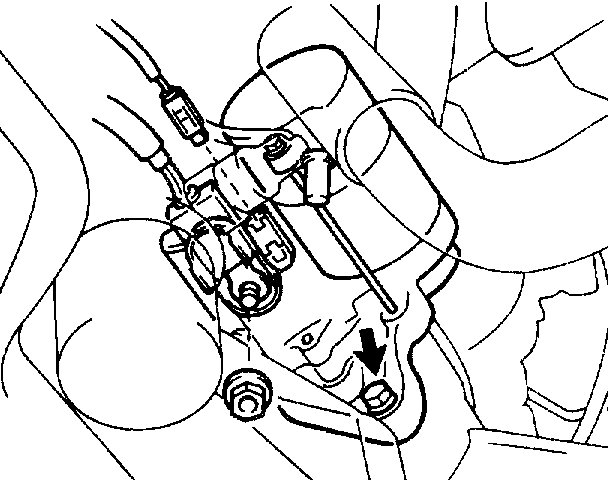

2. CHECK DIAPHRAGM SPRING TIP ALIGNMENT

Using a dial indicator with roller instrument, check the diaphragm spring tip alignment.

Maximum non-alignment: 0.5 mm (0.020 inch)

If alignment is greater than maximum, using SST, adjust the diaphragm spring tip alignment.

SST 09333-00013

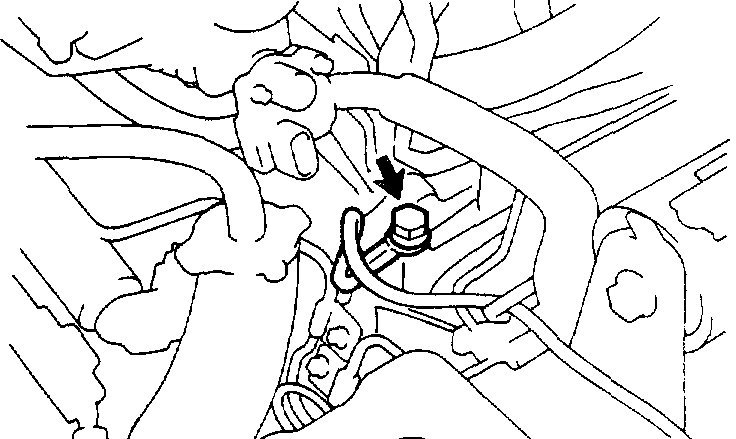

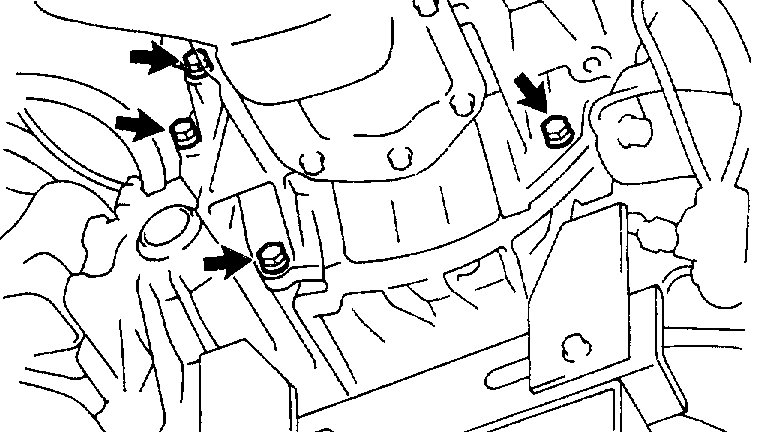

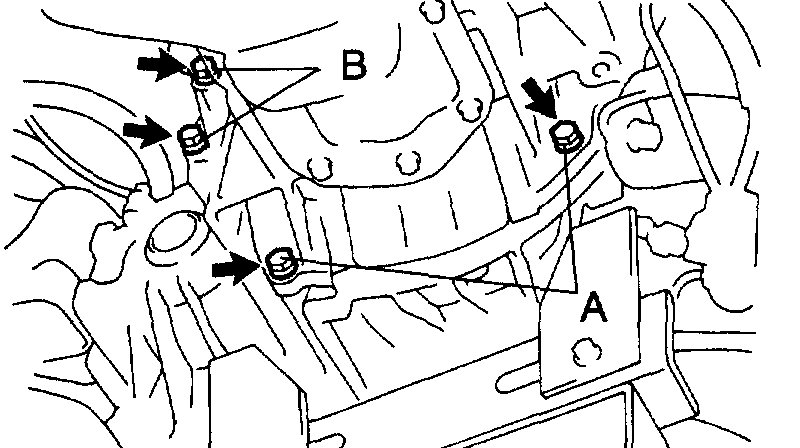

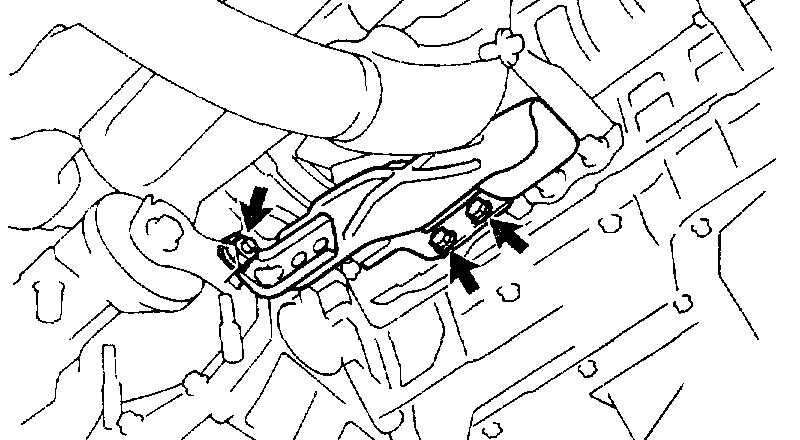

3. INSTALL BOOT AND RELEASE FORK SUPPORT TO TRANSAXLE

Torque: 37 Nm (375 kgf-cm, 27 ft. lbs.)

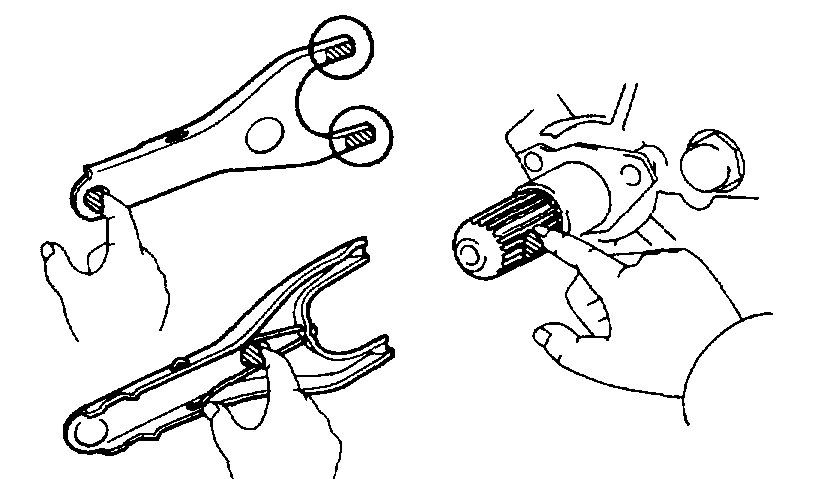

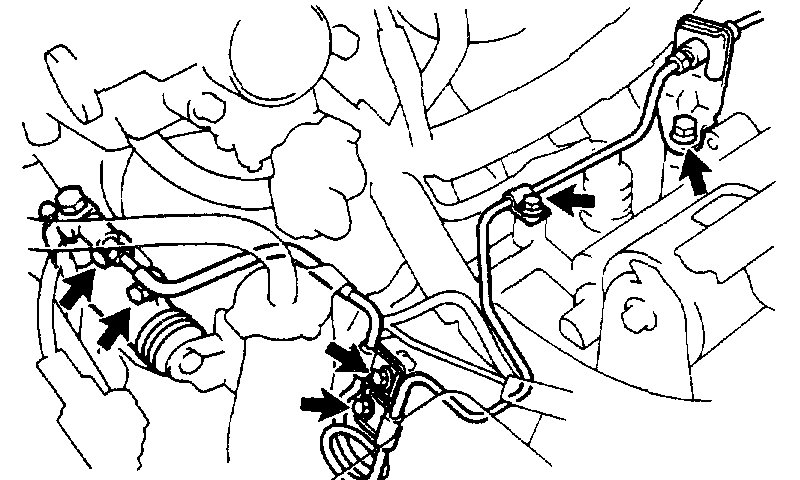

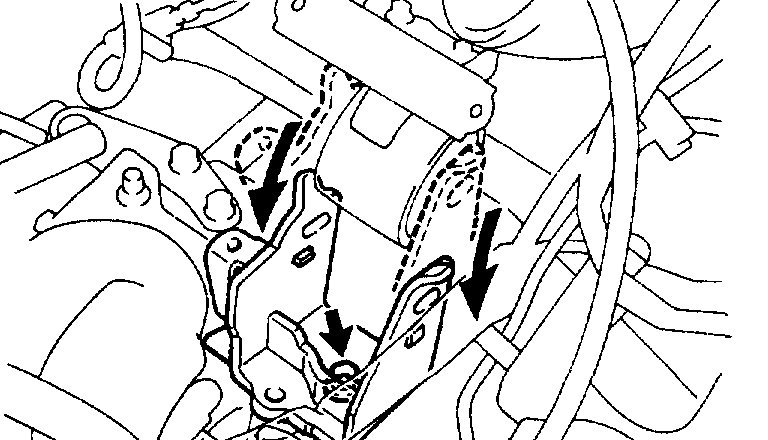

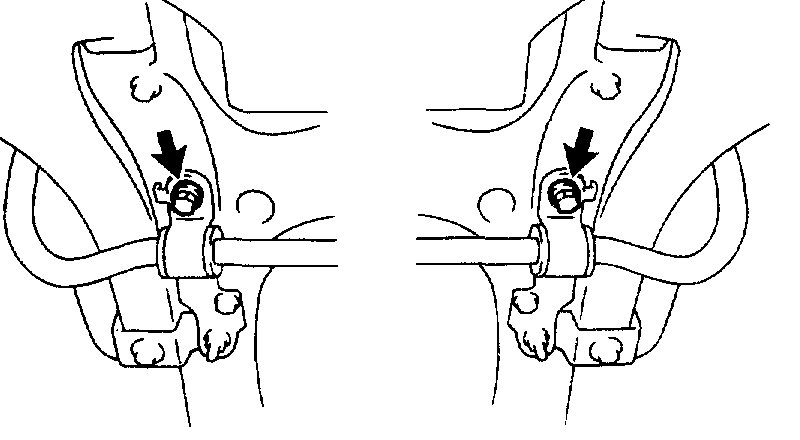

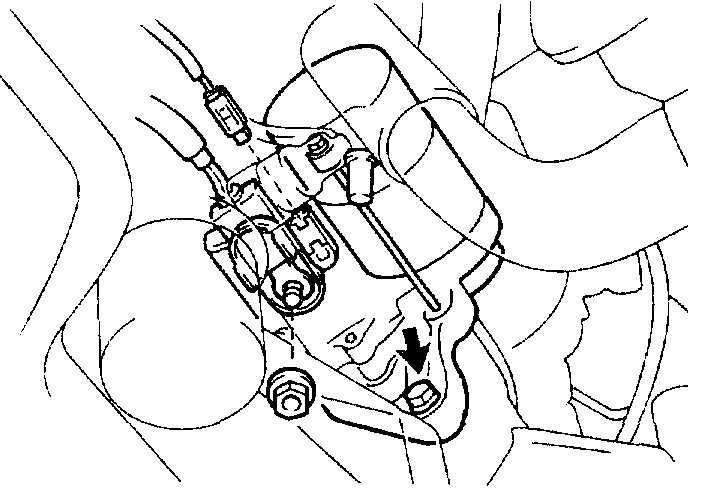

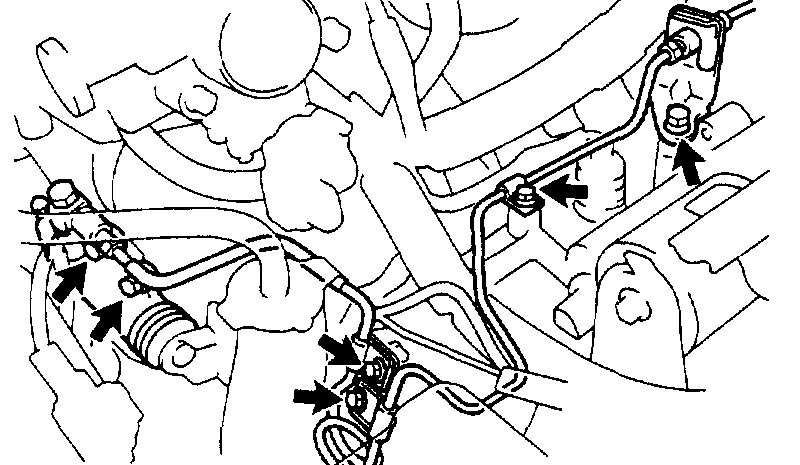

4. APPLY MOLYBDENUM DISULPHIDE LITHIUM BASE GREASE (NLGI NO. 2)

a. Apply molybdenum disulphide lithium base grease to the release fork and release bearing contact point, release fork and push rod contact point and release fork and pivot point.

b. Apply molybdenum disulphide lithium base grease to the clutch spline.

HINT: Recommended grease part number 08887-01706 (100g).

5. INSTALL RELEASE BEARING AND FORK TO TRANSAXLE

Install the bearing to the release fork, and then install them to the transaxle.

6. INSTALL TRANSAXLE TO ENGINE

Check out the diagrams (Below). Please let us know what happens.

Images (Click to make bigger)

Wednesday, May 26th, 2021 AT 6:42 PM