Thursday, November 3rd, 2016 AT 1:07 PM

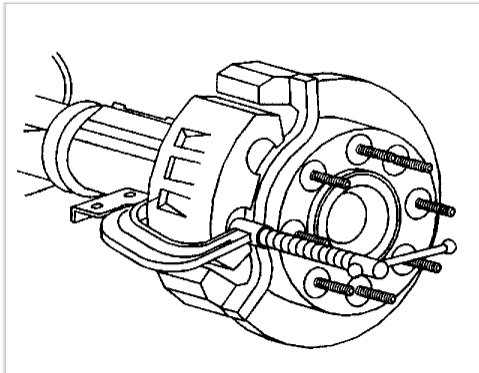

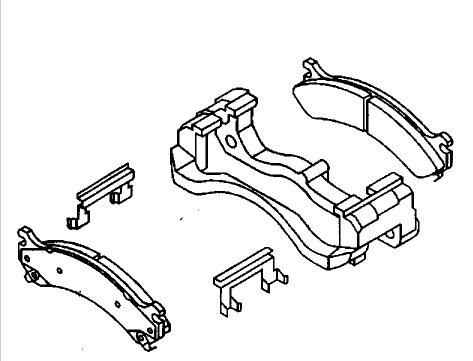

Initially looked at Nakamoto but are now out of stock. So now do not know. ELine, R1, HanSell, and others but read a lot of opposite information on line. Zinc coated or not, drilled slotted versus not, etc. I do only commute and city driving. No towing or fast driving. I would prefer a choice that lasts and has no chance of warping. Perhaps slotted is a good choice but have no idea of brand and model. See that some offer lifetime warranty others only six to twelve months. Which seems to short for a rotor lifetime.