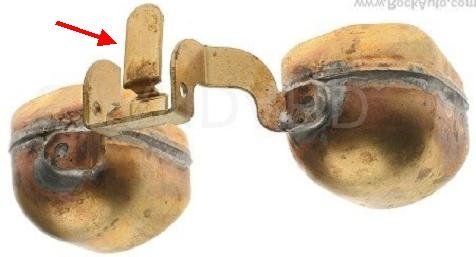

Remove the six screws on top, then lift the cover off. The accelerator pump piston will come with it. As I recall, I think you will need to unscrew the inlet valve for clearance. The float is held in place with a 1"-long metal rod. Pull up on the silver horseshoe-shaped metal strip. Once the inlet valve is out of the way, the float just lifts up. My nifty red arrow is pointing to the tab to adjust to change the mixture.

Making this adjustment is impossible by eye because a very tiny change makes a big difference in the mixture. If you get it too high, the float will hit the cover before it pushes the inlet valve closed. That will result in gas overflowing into the intake manifold.

The rebuild kits used to come with a hard paper gauge for checking the float height, but I never had much luck with them. If you clamp something to the bowl to hold the metal strip in place, which holds the float's pivot rod in place, you can run the engine with the cover removed. You cannot adjust the mixture this way with an exhaust gas analyzer because some extra gas will enter through the accelerator pump's port. All you can do this way is observe the height the float is sitting at, and you can adjust the tang on the float to change its height. This will get a little messy because the gas will spray from the inlet valve. When I did this, I would hold the float's tang against the valve to keep the valve closed, then wait for the gas in the bowl to be used up. Wait for the engine to stall, or have a helper stop it. Release the float, then make the adjustment. Only a few drops of gas will run in once the fuel pump is no longer running.

As a point of interest, in an attempt to get better fuel mileage when driving two hours to college, I modified the rods in the carburetor for my 1972 Dart. First I sanded them down to a slightly smaller diameter, then, if you remove the piston they are attached to, you will find a spring inside it. I cut off about 1/8" of that spring. The piston is held down by intake manifold vacuum. That keeps the jets closed at idle and during normal cruising speeds. When it becomes necessary to pass a bunch of cars, you need to push further on the accelerator pedal before you lose enough vacuum for the spring to push the piston up and open the jets. This gave me better fuel mileage since the jets did not open so often. Once they did finally open, the sanded rods let more fuel in, and off I went into the sunset with my hair streaming straight back! That car with the 318 c.I. Was already fun to drive. This modification was by no means scientific, but it sure had an effect on how many cars I passed.

Image (Click to make bigger)

Tuesday, October 23rd, 2018 AT 8:20 PM