Good morning,

First, never never add sealer to the system. That stuff causes more issues and never does anything for a leak. It most likely failed the expansion valve in the system.

https://www.2carpros.com/articles/air-conditioner-leak-detection

You need to get a full set of gauges and give me both the high and low side readings when it is not running and when it is running. Then I can help you with diagnosing this issue.

You can rent a set of gauges at a parts store.

You will need at least a expansion valve and a dryer to start.

https://www.2carpros.com/articles/re-charge-an-air-conditioner-system

Roy

Removal and Installation

NOTICE: Motorcraft(R) Electric Compressor Oil only must be used as a refrigerant system lubricant for hybrid vehicles. Addition of any oil other than Motorcraft(R) Electric Compressor Oil to the hybrid vehicle refrigerant system will damage the electric Air Conditioning (A/C) compressor and contaminate the refrigerant system. Refer to the Refrigerant Oil Adding procedure.

1. Recover the refrigerant.

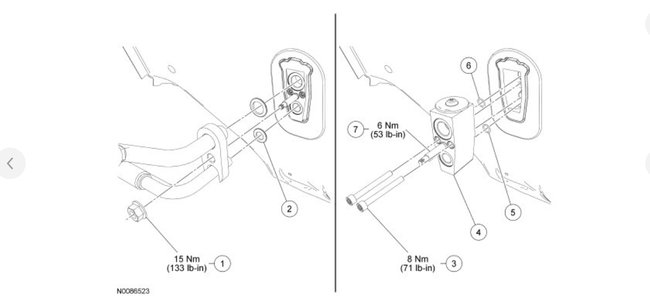

2. Remove the Thermostatic Expansion Valve (TXV) fitting nut and disconnect the fitting.

- Discard the gasket seals.

- To install, tighten to 15 Nm (133 lb-in).

3. Remove the 2 TXV (Thermostatic Expansion Valve) bolts and the TXV (Thermostatic Expansion Valve).

- Discard the O-ring seals.

- To install, tighten to 8 Nm (71 lb-in).

4. NOTICE: Motorcraft(R) Electric Compressor Oil only must be used as a refrigerant system lubricant for hybrid vehicles. Addition of any oil other than Motorcraft(R) Electric Compressor Oil to the hybrid vehicle refrigerant system will damage the electric Air Conditioning (A/C) compressor and contaminate the refrigerant system. Refer to the Refrigerant Oil Adding procedure.

To install, reverse the reverse the removal procedure.

- If the TXV (Thermostatic Expansion Valve) stud has become loose during removal, or has been removed for any reason, tighten the TXV (Thermostatic Expansion Valve) stud to 6 Nm (53 lb-in) before the TXV (Thermostatic Expansion Valve) fitting nut is reinstalled.

- Install new O-ring seals and gasket seals.

- Add the correct amount of clean PAG oil (non-hybrid) or electric A/C compressor oil (hybrid) to the refrigerant system. For additional information, refer to the Refrigerant Oil Adding procedure.

5. Evacuate, leak test and charge the refrigerant system.

Removal and Installation

NOTE: The receiver/drier fitting studs can be removed and installed separately from the receiver/drier and are available as service parts. If only the fitting studs are damaged, it is not necessary to install a new receiver/drier.

NOTE: Installation of a new receiver/drier is not required when repairing the A/C system, except when there is physical evidence of contamination from a failed A/C compressor or damage to the receiver/drier. Damage to the receiver/drier includes leaks, physical damage to the receiver/drier shell or desiccant, or moisture contamination. Moisture contamination results only from a complete loss of refrigerant, and equalization of the refrigerant system pressure with atmospheric pressure for a period longer than one hour. If even a slight amount of positive refrigerant pressure is present in the refrigerant system before repairs are carried out, a new receiver/drier should not be installed.

1. Recover the refrigerant.

2. Remove the front bumper cover. For additional information, refer to Section 501-19 See: Bumper.

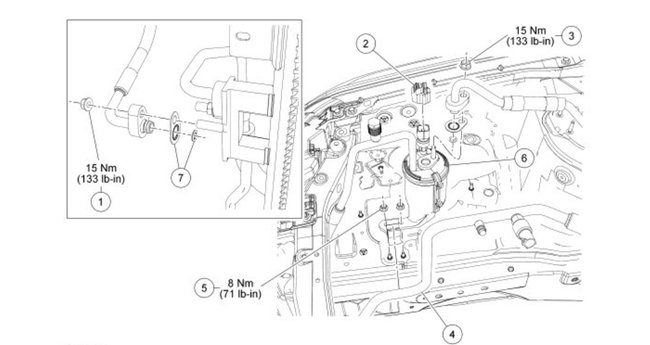

3. Remove the condenser outlet fitting nut and disconnect the fitting.

- Discard the O-ring seal and gasket seal.

- To install, tighten to 15 Nm (133 lb-in).

4. Disconnect the A/C pressure transducer electrical connector.

5. Remove the receiver/drier outlet fitting nut and disconnect the fitting.

- To install, tighten to 15 Nm (133 lb-in).

- Discard the O-ring seal and gasket seal.

6. Detach the evaporator outlet line from the receiver/drier bracket clip.

7. Remove the 2 receiver/drier nuts.

- To install, tighten to 8 Nm (71 lb-in).

8. Remove the receiver/drier.

9. To install, reverse the removal procedure.

- Install new gasket seals and O-ring seals.

- Lubricate the refrigerant system with the correct amount of clean PAG oil.

10. Evacuate, leak test and charge the refrigerant system.

Images (Click to make bigger)

Saturday, June 29th, 2019 AT 5:27 AM