JUST SOME "EXPERIENCE" THOUGHTS

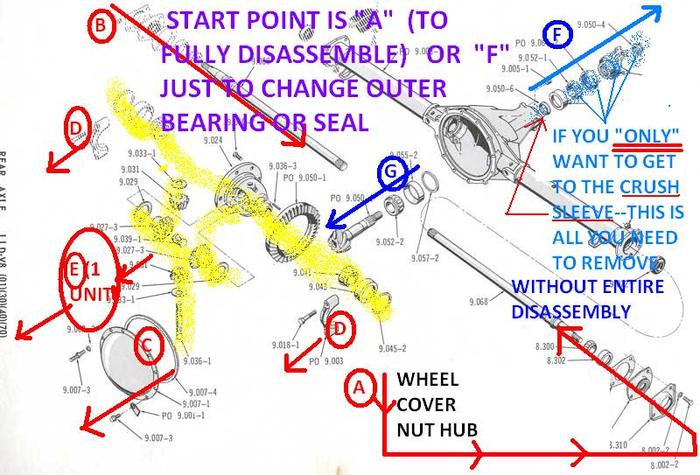

TAKING THE OLD ORIGINAL 2 PC AXLES OUT (IF THAT'S WHAT YOU HAVE) THEY ARE IDENTIFIED BY HAVING A BEARING CAP LOOKING COVER OVER A BIG NUT.....THIS IS CENTER OF THE FLANGE W/ THE WHEEL REMOVED. A AFTERMARKET 1 PC AXLE IS MOSTLY A FLAT FLANGE W/ NO COVER.

IF YOU STILL HAVE THE ORIGINALS, YOU MUST USE A BIG OLE HUB PULLER TO SEPARATE THE HUB FROM THE TAPERED AXLE, WHEN THIS HUB WAS INSTALLED, SPLINES ON THE AXLE, "CUTS" IT'S OWN GROOVES INTO THE HUBS....SAD THING IS, IF THEY ARE REUSED, THEY REQUIRE 250 FT.LBS. (A MONSTER TORQUE WRENCH) TO PUT THEM BACK TOGETHER.

I'D ALSO GIVE YOU A 1 IN 3 CHANCE, THAT AFTER ALL OF YOUR EFFORTS, THE SPLINES DON'T HOLD UP, AND YOUR AXLE WILL SPIN IN THE HUB......YOU SIT STILL IN GEAR, SHOULD BE MOVING, BUT THE BIG OLE NUT (AND AXLE) SPIN FREE, "SORTA AS IF" ONE WHEEL IS SPINNING IN MUD......THIS ALSO HAPPENS OWN IT'S OWN, ESPECIALLY WHEN "ONE" PUTS HIS BABY THRU H.ELL. EITHER WAY, YOU GOTTA GET ANOTHER SET AND START OVER

......UNLESS, YOU INSTALL 1 PC AXLES AT THIS POINT

THERE IS NO TORQUING REQUIRED

YOU CAN UNBOLT YOUR OLD AXLES SLIDE EVERYTHING OUT....HACKSAW THE AXLES OFF NEAR THE HUBS.....THE ONLY PART YOU NEED TO KEEP IS THE BRAKE BACKING PLATE---IT'S TRAPPED BETWEEN THE AXLE AND HUB...NO PULLER NEEDED, THE OLD AXLES WOULD DEFINITELY BE "TOAST" WHEN CUT

INSTALL IS EZ!

I PAID NEARLY $500 FOR MY SET MANY YEARS AGO, WHEN THEY 1ST HIT THE MARKET (I FELT I WOULD NEED THEM) SEEUNS HOW ON MY 1ST THREE JEEPS, I HAD TO GO BACK WITH ORIGINAL CRAP, THAT'S ALL THERE WAS, WHEN YOU SPUN AN AXLE!

WELL.....KNOCK ON WOOD, I BOUGHT MY 1 PC. AXLES, 4 INNER SEALS, 4 OUTER SEALS, 4 BEARINGS......JUST TO HAVE A SPARE SET OF THE SMALL ITEMS. THIS EXPENSIVE BOX OF GOODIES IS STILL IN MY CLOSET. I GOT JEEP #6 IN ABOUT 1992. THUS FAR "MR. JEEP" HAS NOT "SPUN AN AXLE" YET.....THAT'S 20 YEARS, W/ SAME WHEEL BEARINGS/ SEALS....WHO KNOWS WHAT IT'S PREVIOUS HISTORY IS!

MORAL OF THAT STORY.....I AM READY, WHEN "TIME" ROLLS AROUND

I REALLY LOOKED AROUND FOR YOU

WE MAY CAN GET THIS AT A BETTER DEAL, THIS DOES NOT LOOK SO BAD, AT IT'S PRESENT RATE

http://www.4wd.com/Jeep-Drivetrain-Jeep-Axles-Differentials/AMC-20-Rear-Axle-Kit.aspx?t_c=12&t_s=237&t_pt=5564&t_pn=G%2f296-2025-3

AS FAR AS REAR END GOES THINK ABOUT A STANDARD DIFF VS. A "TRAC-LOC" (POSI-TRACTION ON THE REAR--FRONT IS OPTIONAL LATER ON)

SO WE'RE LOOKIN' AT RING AND PINION--ITS BEARINGS AND CRUSH SLEEVE..........SIDE BEARINGS.....CARRIER OR NOT????.....DIFF JUICE DEPENDING ON WHAT SYSTEM YOU USE.......AND OF COURSE "SHIMS"

I'D SAY YOUR BEST SOURCE FOR A VARIETY OF SIZES AND THICKNESSES WILL BE AT ONE OF THOSE "COUNTRY TRANSMISSION SHOPS"....YOU KNOW THE KIND YOU WALK INTO AND IT LOOKS LIKE "HOARDER-VILLE"......THESE GUYS HAVE BEEN HOARDING THIS STUFF FOR 60 YEARS, KNOW RIGHT WHERE IT'S AT, AND DEPENDING ON YOUR 1ST IMPRESSION, YOU CAN GET IT CHEAP OR EVEN FREE!

THIS TECHNIQUE MAY WORK IN HOARDER-VILLE TOO. YOU SOUND LIKE YOU'RE WELL VERSED IN ANY SITUATION

http://www.2carpros.com/questions/1989-mercury-tracer-was-backed-into-need-headlight

SHAKING?

COMPLETELY REMOVE REAR DRIVE SHAFT----STICK 'EM IN 4X4---FRONT WHEELS ARE THE ONLY THING PULLING.....DOES IT GO AWAY???

LET'S NOT EVEN ATTEMPT TO MAKE SHIMS---SEARCH NET IF NOTHING ELSE---DO IT RIGHT!----FULLY UNDERSTAND "PRE-LOAD"---WE'LL PHONE COMMO IF YOU WANT MORE OF MY RURAL ROUTE EXPLANATIONS!

MY AMC JEEP MANUAL SHOWS THE RING AND PINION MARKED WITH "+" AND "-" AND A NUMBER, SUCH AS "+ 3" ON THE RINGTHE NEW RING MAY SAY "+ 1".......A CHART SHOWS THE "TENTATIVE" .002" (2 THOUSANDTHS OF AN INCH. YOU WOULD EITHER "ADD" A .002" SHIM OR "SUBTRACT" .002"

WHAT THIS SORTA MEANS IS THE "SPOT" THAT THE PINION MESHES "BEST"/ "QUIETEST" WITH THE RING. THE NUMBERS ARE THERE SO THAT YOU CAN EZily SHIM IT RIGHT OR CLOSE.......THEY DO STILL WANT YOU TO VERIFY THIS WITH THE DEPTH TOOLS, IN A PINCH, I'D TRUST THE CHART MORE THAN "JIMBOB, THE IMPACT WRENCH GUY"!

THE MEDIC

Wednesday, June 27th, 2012 AT 1:37 AM