Engine are designed with a flywheel or flexplate depending which will be determined by the transmission type i.e. Automatic transmissions use a flexplate while the standard transmission uses a flywheel. Both do essentially the same thing the only different being the flywheel will have a clutch assembly mounted to it while the flexplate will have a torque converter bolted to it. Both are attached to the engine crankshaft and help balance the engine for smooth operation and also both feature a ring gear for the starter motor to operate. Dual mass flywheels have an extra layer that sits between the surface of the clutch disc and the body of the flywheel which can move slightly which helps for smoother shifting, the input shaft of the transmission is fitted into this layer.

What goes wrong?

A flywheel will generally only have two issues, first is the ring gear in which the starter uses to rotate the engine over can wear hindering the starter's operation. The second issue involves the clutch which can cause the flywheel to become grooved or heat checked making the transmission hard to shift or allow the clutch to slip. In either case the flywheel must be replaced or resurfaced when these situations arise.

What's the cost?

Anytime you need to replace a flywheel the transmission needs to be removed. The cost will vary depending on drivetrain options but typically charges will range between $800.00 to $1200.00 (US) plus the cost of the flywheel which can run between $140.00 and $230.00 (US) in most cases.

Flywheel

- Helps balance the engine

- Features a ring gear for the starter

- Holds the clutch assembly

- Bolts to the engine crankshaft

How does it work?

The flywheel is bolted and turns directly with the crankshaft acting as a solid coupler to join the power output of the engine and transfer it to the transmission input shaft. The flywheel also acts as an agent to help start the engine via the starter motor. A flywheel is "timed" to the crankshaft and can only be bolted up one way. This is achieved by offsetting the bolt pattern helping preserve the engine balance when running. When replacing a flywheel mounting bolts should to be tightened to manufacturer's specifications to preserve the flywheel integrity.

Let's see!

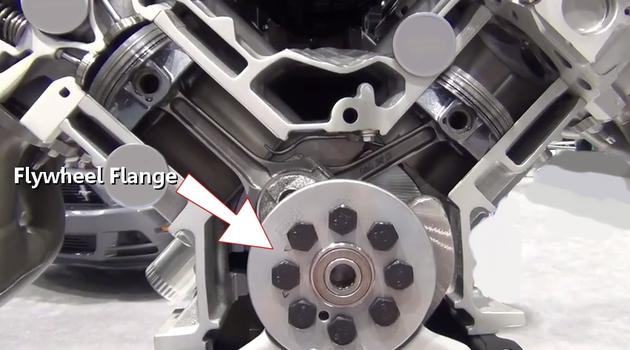

Here is the flywheel mounting flange featured on a cutaway block. In the center

of the crankshaft is a pilot bearing used to support the input shaft of the transmission.

This is what a clutch looks

like when mounted to the flywheel

The dual mass flywheel has made shifting transitions more comfortable.

Questions?

Our certified technicians are ready to answer flywheel questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.