I was hopeful. LOL I'm starting to question if it isn't the IAC but rather an issue with the PCM. I know there are tests related to the IAC but without a code, I don't know which one would benefit you.

I just remembered you gave me a P0507. Here is a diagnostic flow chart specific to that code. All attached pics correlate with the directions. It does require a scanner.

Let me know if this helps.

________________________________________________________________________

2001 Mitsubishi Eclipse GS L4-2350cc 2.4L SOHC MFI

P0507

Vehicle ALL Diagnostic Trouble Codes ( DTC ) Testing and Inspection P Code Charts P0507

P0507

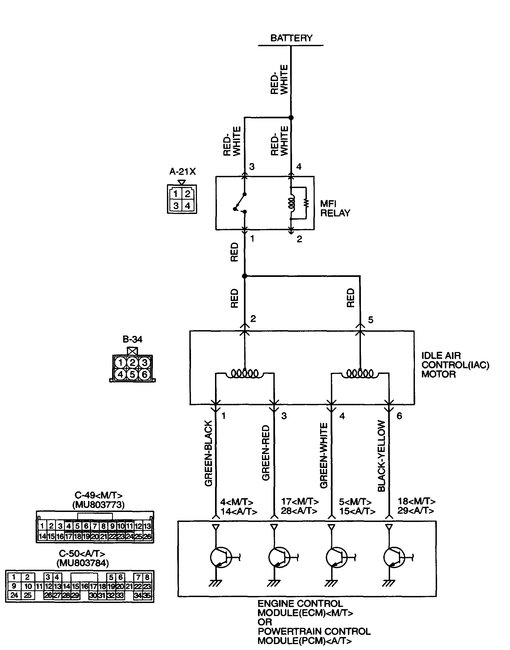

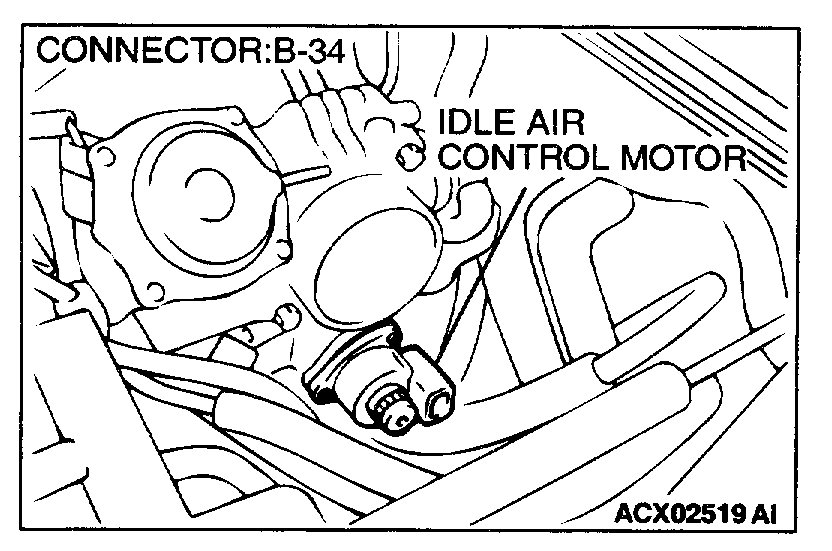

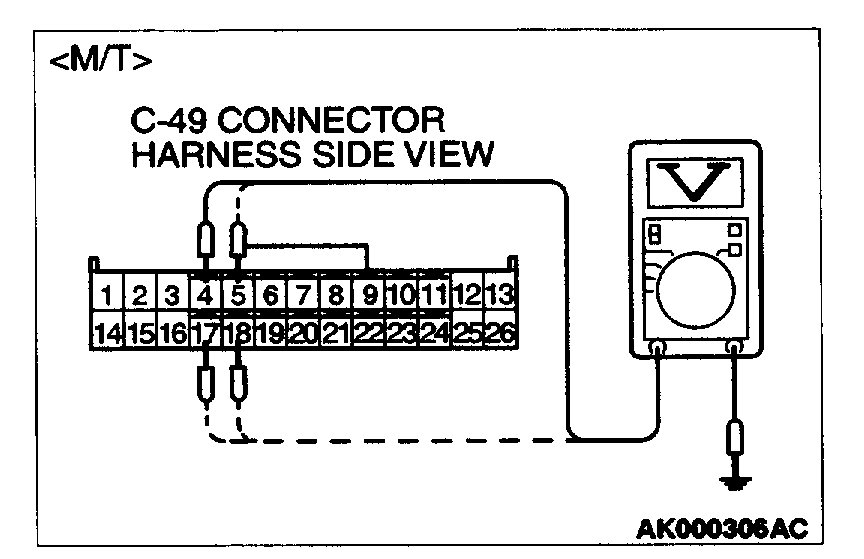

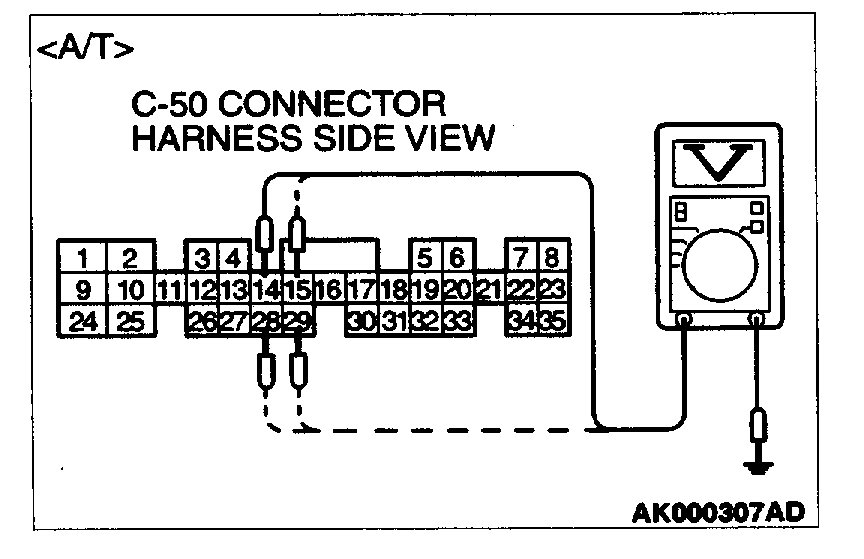

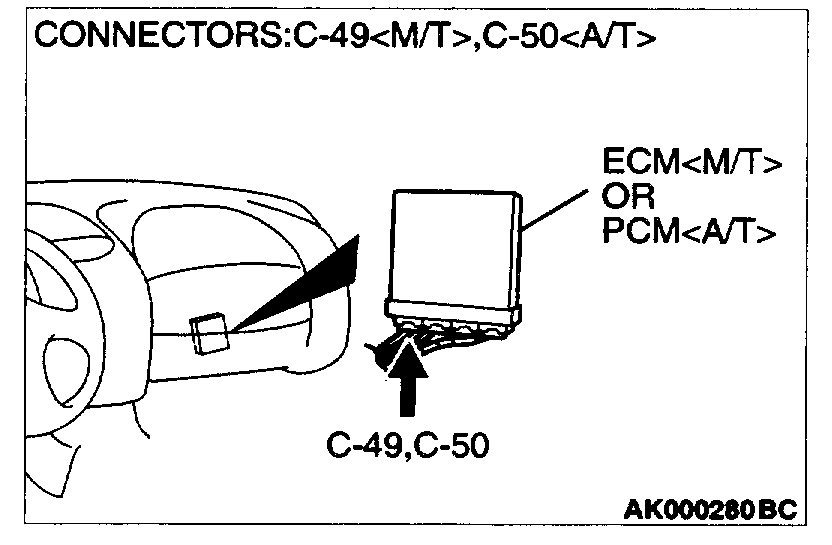

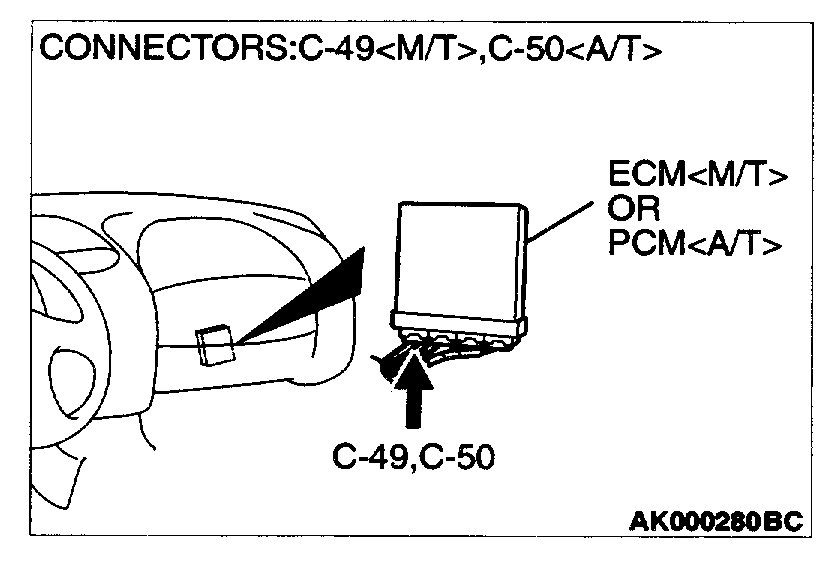

pic 1

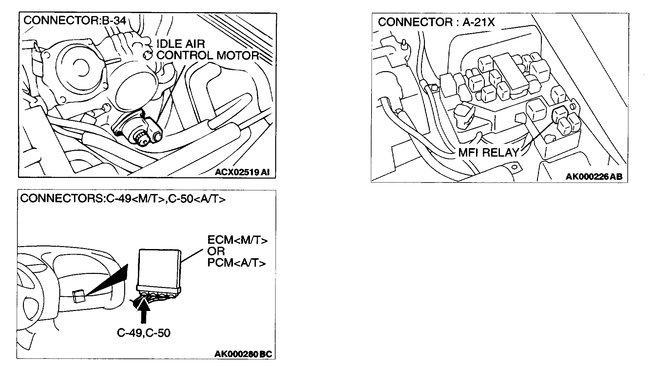

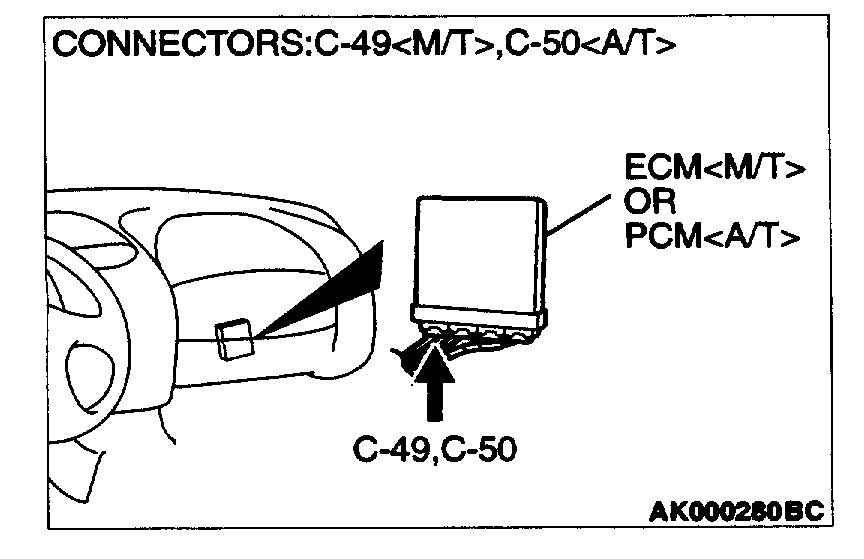

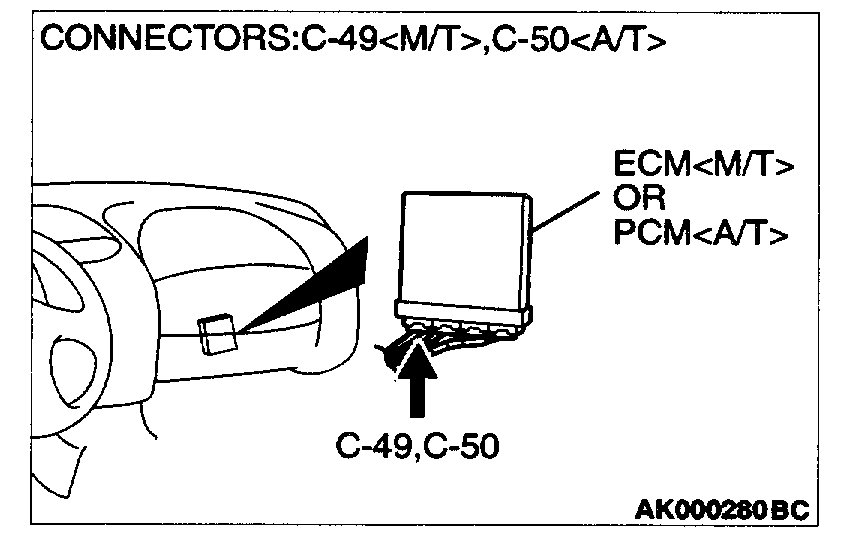

Connectors

pic 2

CIRCUIT OPERATION

- The idle air control motor power is supplied from the MFI relay (terminal 1).

- The ECM (terminals 4, 5, 17, 18) (M/T> or PCM (terminals 14, 15, 28, 29) (A/T> drives the stepper motor by sequentially turning "ON" the power transistors in the ECM (M/T> or PCM (A/T> and providing ground to the idle air control motor (terminals 1, 3, 4, 6).

TECHNICAL DESCRIPTION

- The amount of air taken in during idling is regulated by the opening and closing of the servo valve located in the air passage that bypasses the throttle body.

- If there is a malfunction of the IAC system, the actual engine speed will not be identical to the target engine speed.

- The ECM (M/T> or PCM (A/T> checks the difference between the actual engine speed and the target engine speed.

DTC SET CONDITIONS

Check Conditions

- Vehicle speed has reached 1.5 km/h (0.93 mph) or more at least once.

- Under the closed loop idle speed control.

Judgement Criteria

- Actual idle speed has continued to be higher than the target idle speed by 300 r/min or more for 12 seconds.

Check Conditions

- Vehicle speed has reached 1.5 km/h (0.93 mph) or more at least once.

- Under the closed loop idle speed control.

- The highest atmospheric temperature at the last drive is 45 °C (113 °F) or less.

- Engine coolant temperature is higher than 82 °C (180 °F).

- Battery positive voltage is higher than 10 volts.

- Barometric pressure is higher than 76 kPa (11 psi).

- Intake air temperature is higher than -10 °C (14 °F).

Judgement Criteria

- Actual idle speed has continued to be higher than the target idle speed by 200 r/min or more for 12 seconds.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Idle air control motor failed.

- Open or shorted idle air control motor circuit, or loose connector.

- ECM failed. (M/T>

- PCM failed. (A/T>

DIAGNOSIS

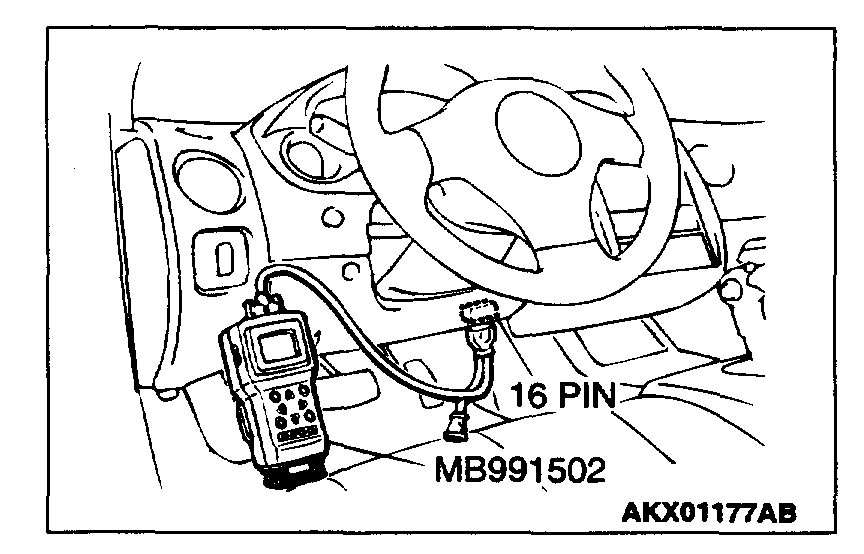

Required Special Tools

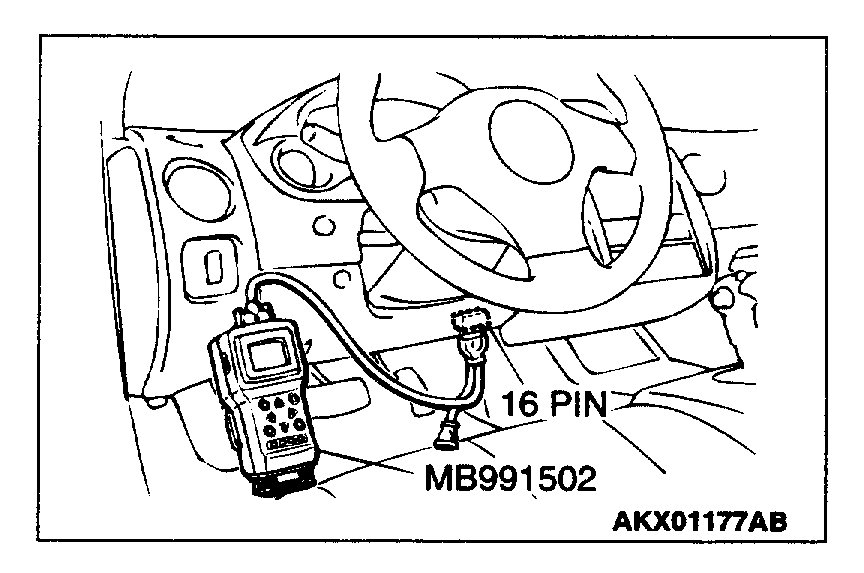

MB991502: Scan Tool (MUT-II)

MB991709: Test harness

pic 3

STEP 1. Using scan tool MB991502, read the diagnostic trouble code (DTC).

CAUTION: To prevent damage to scan tool MB991502, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991502.

1. Connect scan tool MB991502 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Set scan tool MB991502, read the DTC.

4. Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the diagnostic trouble code other than P0507 output?

YES: Refer to Diagnostic Trouble Code Chart under "Trouble Code Descriptions".

NO: Go to Step 2.

STEP 2. Check the intake system vacuum teak.

Q: Are there any abnormalities?

YES: Go to Step 3.

NO: Repair or replace it. Then go to Step 14.

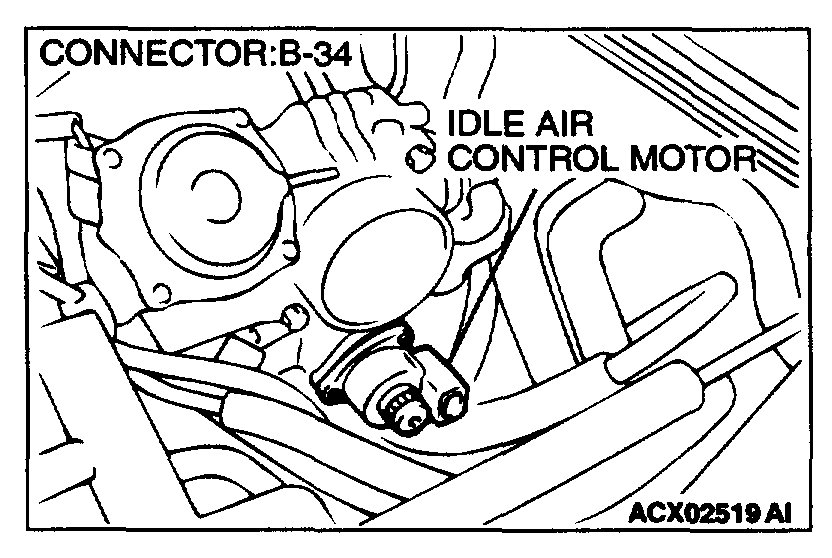

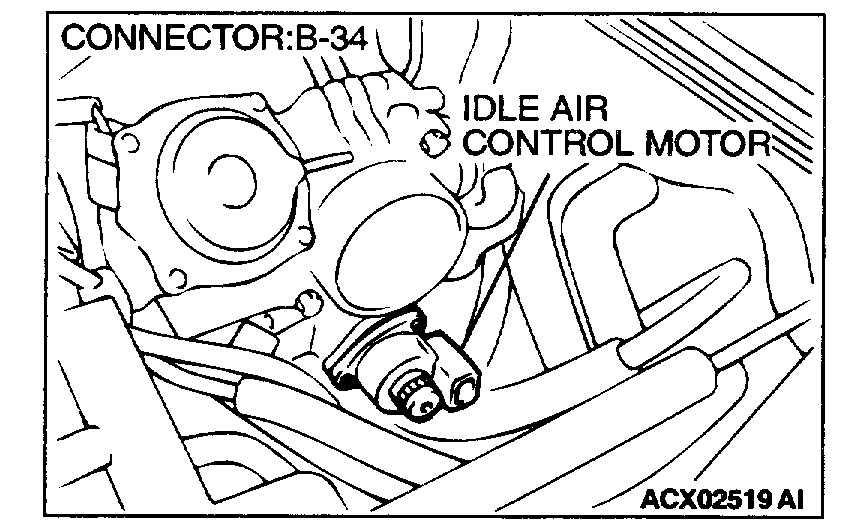

Pic 4

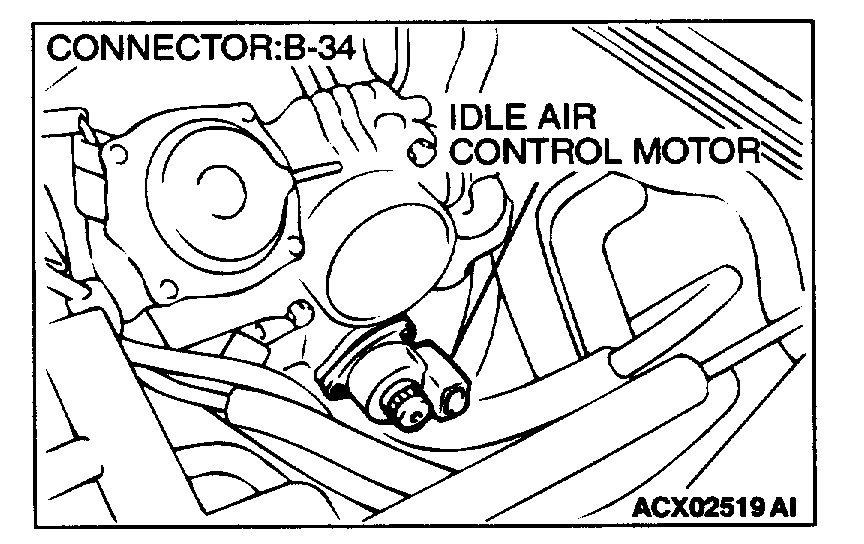

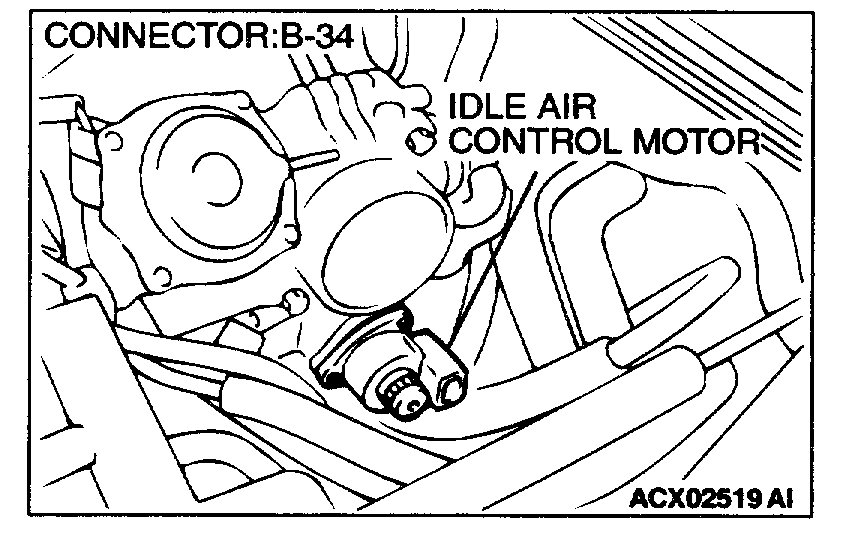

STEP 3. Check connector B-34 at idle air control motor for damage.

Q: Is the connector in good condition?

YES: Go to Step 4.

NO: Repair or replace it. Refer to Harness Connector Inspection. Then go to Step 14.

Pic 5

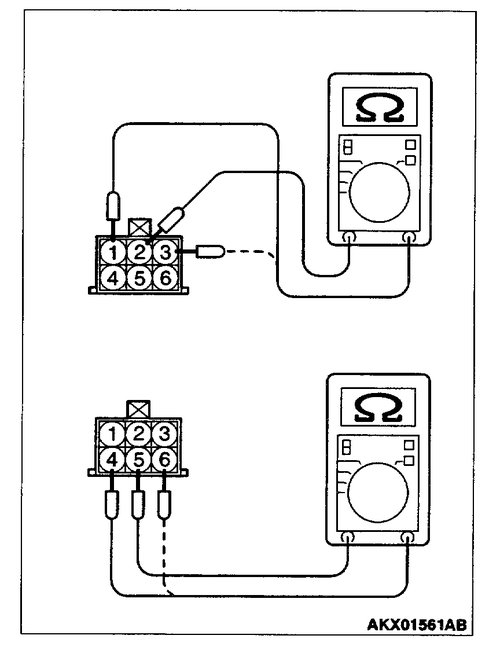

pic 6

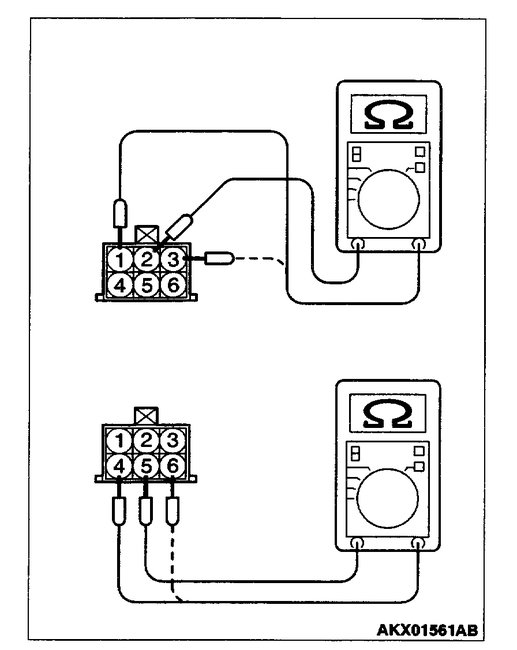

STEP 4. Check the idle air control motor coil resistance.

1. Disconnect the idle air control motor connector B-34.

2. Measure the resistance between idle air control motor connector terminal 2 and either terminal 1 or terminal 3.

Standard value: 28 - 33 ohm [at 20 °C (68 °F)]

3. Measure the resistance between idle air control motor connector terminal 5 and either terminal 4 or terminal 6.

Standard value: 28 - 33 ohm [at 20 °C (68 °F)]

Q: Is the resistance normal?

YES: Go to Step 5.

NO: Replace the idle air control motor. Then go to Step 14.

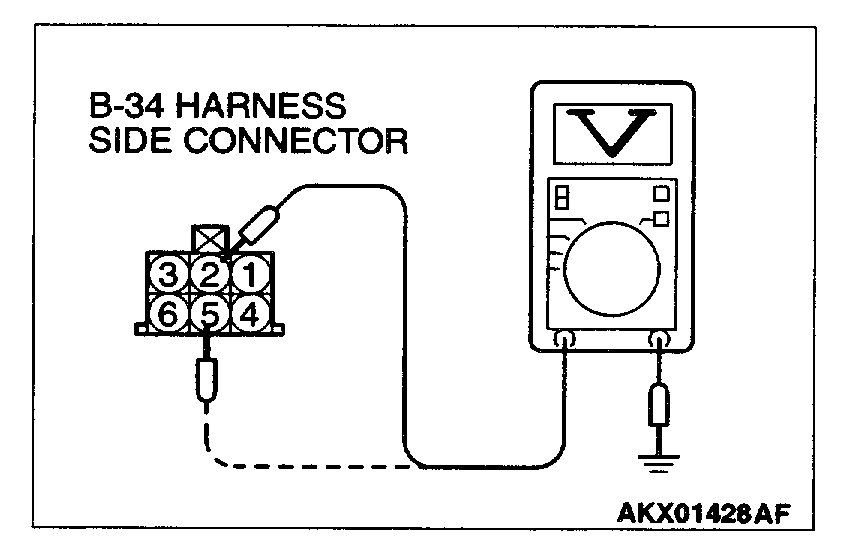

Pic 7

STEP 5. Check the power supply voltage at idle air control motor harness side connector B-34.

1. Disconnect the connector B-34 and measure at the harness side.

2. Turn the ignition switch to the "ON" position.

3. Measure the voltage between terminal 2, 5 and ground.

- Voltage should be battery positive voltage.

4. Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the voltage normal?

YES: Go to Step 7.

NO: Go to Step 6.

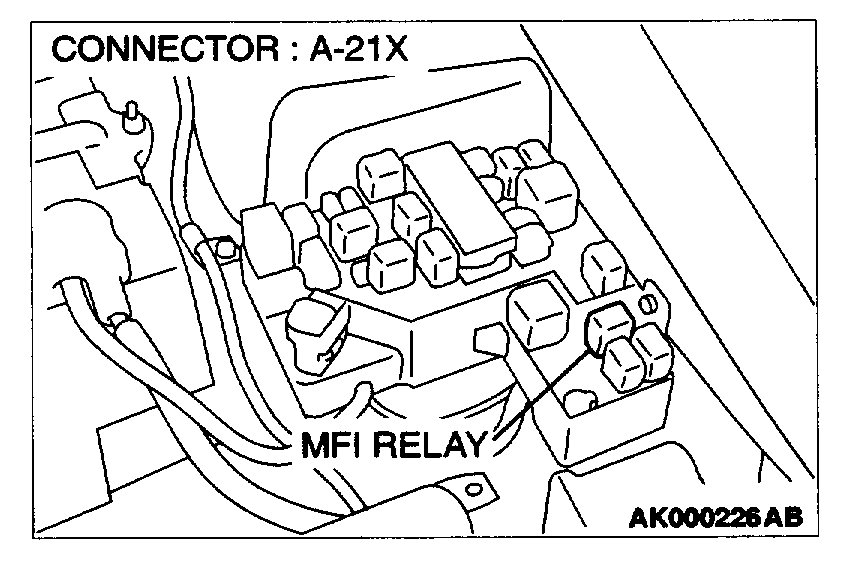

Pic 8

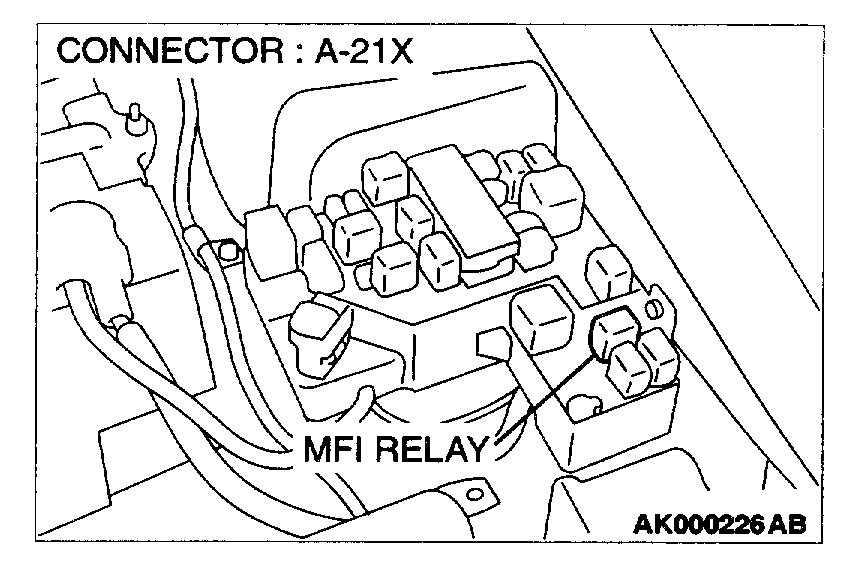

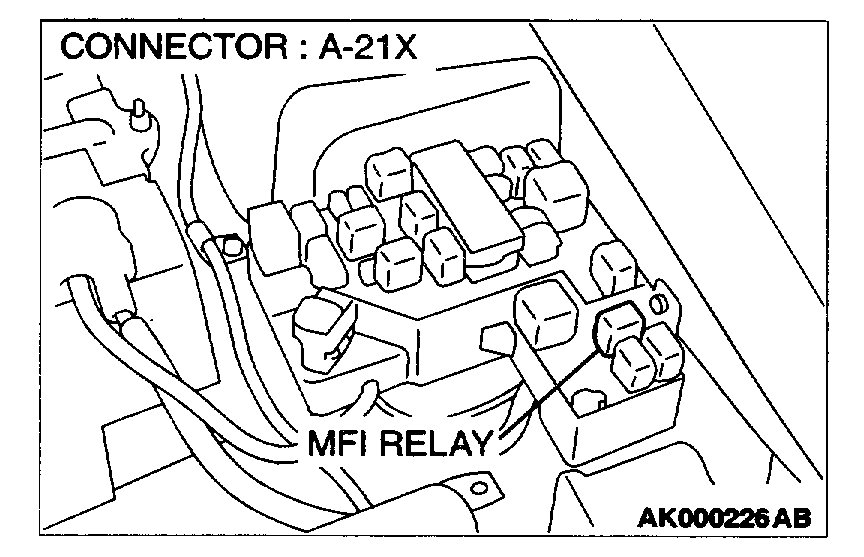

STEP 6. Check connector A-21X at MFI relay for damage.

Q: Is the connector in good condition?

YES: Repair harness wire between MFI relay connector A-21X terminal 1 and idle air control motor connector B-34 terminal 2, 5 because of open circuit or short circuit to ground. Then go to Step 14.

NO: Repair or replace it. Refer to Harness Connector Inspection. Then go to Step 14.

Pic 9

pic 10

STEP 7. Check the power supply voltage at ECM connector C-49 (M/T> or PCM connector C-50 (A/T> by backprobing

1. Do not disconnect the connector C-49 (M/T> or C-50 (A/T>.

2. Measure the voltage between terminal (4, 5, 17, 18) (M/T> or (14, 15, 28, 29) (A/T> and ground by backprobing.

- The voltage is 1 V or lower for approximately 3 seconds, then changes to the battery positive voltage when the

Ignition switch is turned from the "LOCK" (OFF) position to the "ON" position.

3. Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the voltage normal?

YES: Go to Step 10.

NO: Go to Step 8.

Pic 11

STEP 8. Check connector C-49 at ECM (M/T> or connector C-50 at PCM (A/T> for damage.

Q: Is the connector in good condition?

YES: Go to Step 9.

NO: Repair or replace it. Refer to Harness Connector Inspection. Then go to Step 14.

Pic 12

pic 13

STEP 9. Check for open circuit and short circuit to ground between idle air control motor connector B-34 and ECM connector C-49 (M/T> or PCM connector C-50 (A/T>.

A. Idle air control motor connector B-34 terminal 1 and ECM connector C-49 terminal 4 (M/T> or PCM connector C-50 terminal 14 (A/T>.

B. Idle air control motor connector B-34 terminal 3 and ECM connector C-49 terminal 17 (M/T> or PCM connector C-50 terminal 28 (A/T>.

C. Idle air control motor connector B-34 terminal 4 and ECM connector C-49 terminal 5 (M/T> or PCM connector C-50 terminal 15 (A/T>.

D. Idle air control motor connector B-34 terminal 6 and ECM connector C-49 terminal 18 (M/T> or PCM connector C-50 terminal 29 (A/T>.

Q: Is the harness wire in good condition?

YES: Replace the ECM or PCM. Then go to Step 14.

NO: Repair it. Then go to Step 14.

Pic 14

STEP 10. Check connector C-49 at ECM (M/T> or connector C-50 at PCM (A/T> for damage.

Q: Is the connector in good condition?

YES: Go to Step 11.

NO: Repair or replace it. Refer to Harness Connector Inspection. Then go to Step 14.

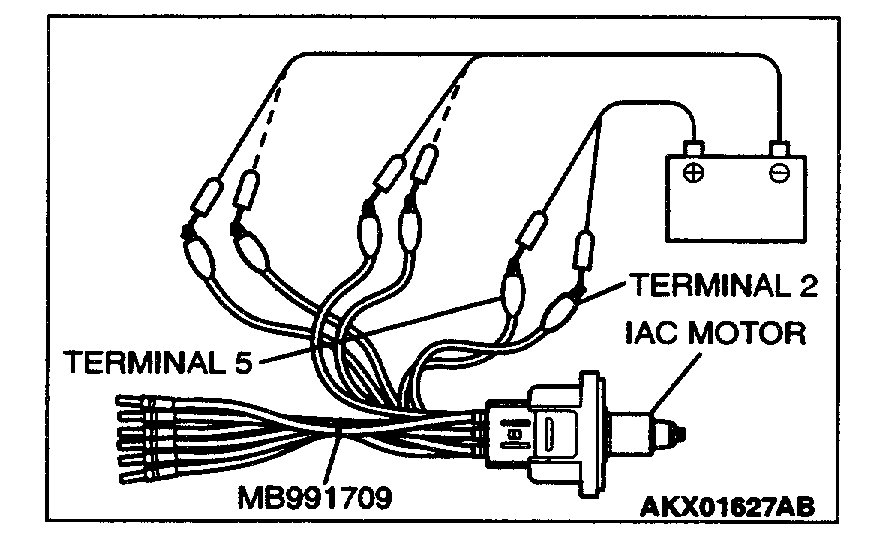

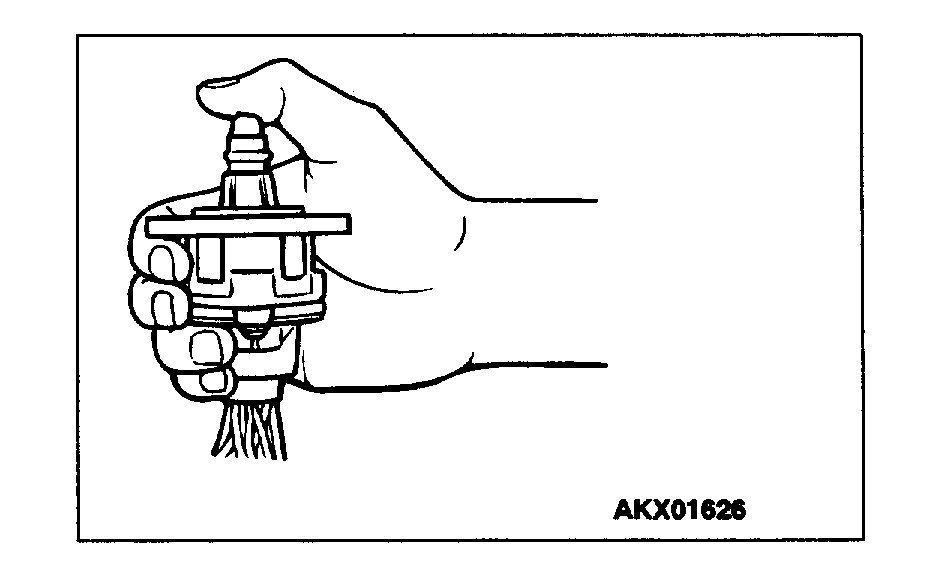

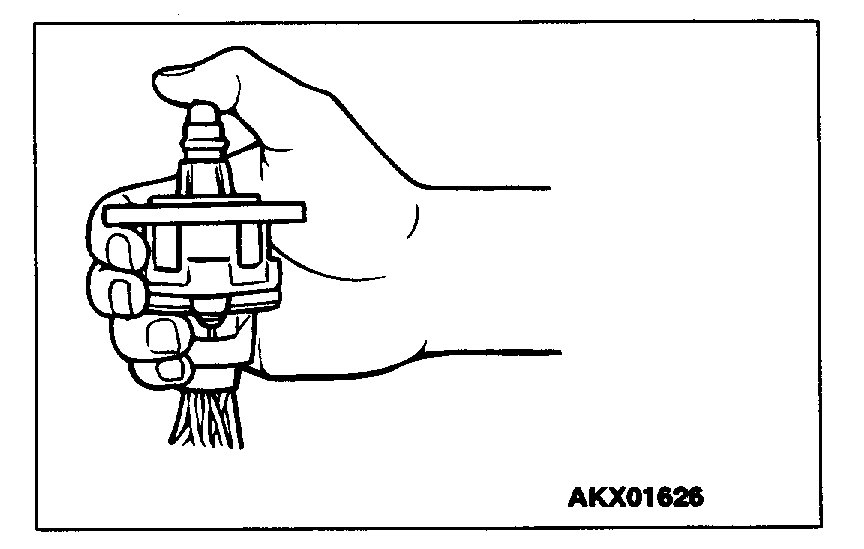

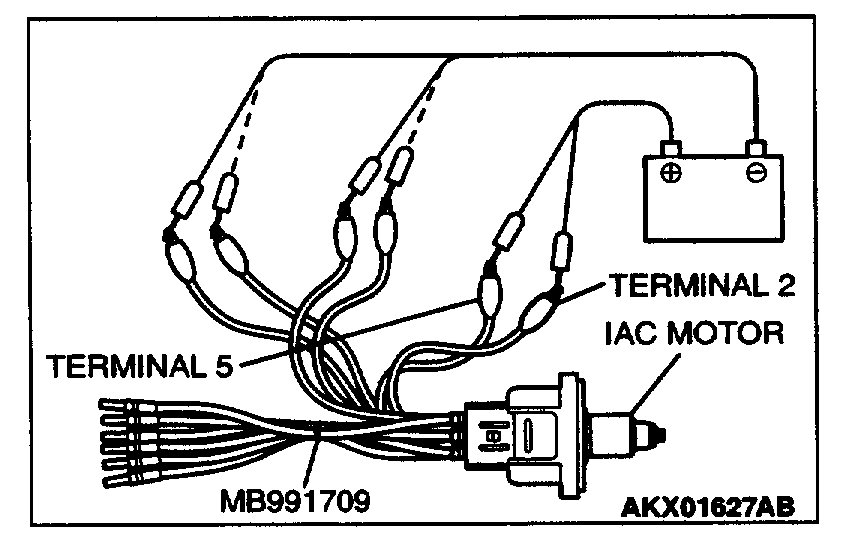

STEP 11. Check the idle air control motor operation using special tool MB991709.

Pic 15

1. Remove the idle air control motor.

2. Connect special tool MB991709 to the idle air control motor. (All terminals should be connected.)

3. Use the jumper wires to connect terminal 2 of the idle air control motor connector to the battery (+) terminal.

4. Check the ensure that the motor operates when the terminals 1 and 3 of the idle air control motor connector are respectively connected to the battery (-) terminal using a jumper wire.

- Vibration should be present at each application of voltage to test clip combination.

Pic 16

5. Then. Use jumper wires to connect the terminal 5 of the idle air control motor connector to the battery (+) terminal.

6. Check the ensure that the motor operates when the terminals 4 and 6 of the idle air control motor connector are respectively connected to the battery (-) terminal using a jumper wire.

- Vibration should be present at each application of voltage to test clip combination.

Pic 17

7. Install the idle air control motor. Refer to Throttle Body - Disassembly and Assembly.

Q: Is the idle air control motor operating properly?

YES: Go to Step 12.

NO: Replace the idle air control motor. Then go to Step 14.

Pic 18

pic 19

STEP 12. Check for harness damage between MFI relay connector A-21X terminal 1 and idle air control motor connector B-34 terminal 2, 5.

Q: Is the harness wire in good condition?

YES: Go to Step 13.

NO: Repair it. Then go to Step 14.

Pic 20

pic 21

STEP 13. Check for harness damage between idle air control motor connector B-34 and ECM connector C-49 (M/T> or PCM connector C-50 (A/T>.

A. Idle air control motor connector B-34 terminal 1 and ECM connector C-49 terminal 4 (M/T> or PCM connector C-50 terminal 14 (A/T>.

B. Idle air control motor connector B-34 terminal 3 and ECM connector C-49 terminal 17 (M/T> or PCM connector C-50 terminal 28 (A/T>.

C. Idle air control motor connector B-34 terminal 4 and ECM connector C-49 terminal 5 (M/T> or PCM connector C-50 terminal 15 (A/T>.

D. Idle air control motor connector B-34 terminal 6 and ECM connector C-49 terminal 18 (M/T> or PCM connector C-50 terminal 29 (A/T>.

Q: Is the harness wire in good condition?

YES: Replace the ECM or PCM. Then go to Step 14.

NO: Repair it. Then go to Step 14.

STEP 14. Test the OBD-II drive cycle.

1. Carry out a test drive with the drive cycle pattern. Refer to Procedure 6 - Other Monitor.

2. Check the diagnostic trouble code (DTC).

Q: Is the DTC P0507 is output?

YES: Retry the troubleshooting.

NO: The inspection is complete.

______________________________________

Let me know if this is something you could do.

Joe

Images (Click to make bigger)

Saturday, April 18th, 2020 AT 10:52 PM