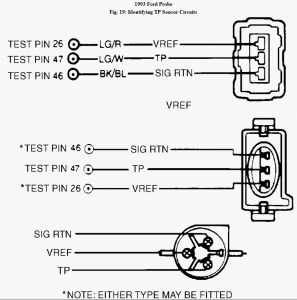

I have cleared all my codes by disconnecting the battery for a long period of time, I still get a 121 TPS out of range code. I thought I was getting this code because I had unplugged it but it has come back, I have tested this according to the chilton manual.

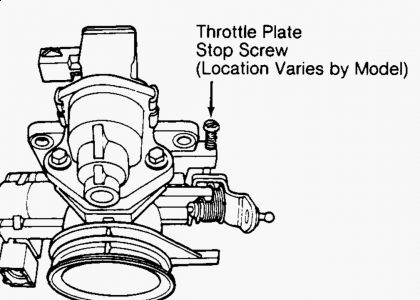

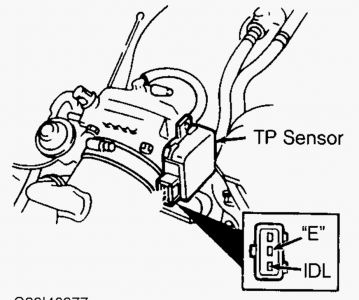

1. Insert 0.1 mm feeler gauge between stop lever and throttle stop screw, verify there is continuity between terminals IDL and E

-yes

2. Replace feeler gauge w/ 0.7 mm and verify there is NO continuity

- there IS still continuity according to my meter

3. Then open throttle wide and verify there is still no continuity

-there still IS continuity, about 2-3 k ohms

4. Insert 0.1 mm feeler gauge between stop lever and throttle stop screw, verify there is NO continuity between terminals POW and E

-there still IS continuity.

5. Replace feeler gauge w/ 0.7 mm and verify there is NO continuity

-still is continuity.

6. Open throttle wide and verify there is continuity between POW and E

-yes

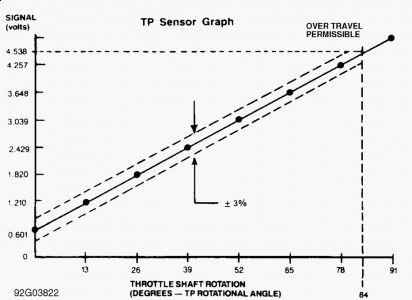

basically, no matter what terminals I am testing. I am getting continuity all the time. A smooth flow of numbers rising everytime I open the throttle, the wider the throttle, the higher the numbers, I have good voltage as I mentioned earlier in the post, does this mean my tps is bad? I heard there is a way to set the TPS by the fan method, by turning it until the fans kick on in diagnostic mode then turning it back a little til they shut off. No matter how far I turn the tps the fans do not kick on. Are there any other ways I can test this to be sure this is the problem? They are over 100 dollars I can't really afford to just replace it

Sunday, October 22nd, 2017 AT 1:36 PM

(Merged)