Welcome to 2CarPros.

First, if you notice a misfire, the light should be on. Confirm it is working when you first turn the key on. It should turn off after a few seconds. With that in mind, I still need you to check for trouble codes. All you need to do it is a test light. Follow the directions in this link:

https://www.2carpros.com/articles/ford-lincoln-mercury-obd1-1995-and-earlier-diagnostic-trouble-code-definition-and-retrieval

If no codes are found, it could be many possible issues. I am going to provide links on the different things to check.

Next, if you question that a possible head gasket can be an issue, here is a link that shows how to check:

https://www.2carpros.com/articles/head-gasket-blown-test

Next, you may have a plugged catalytic converter. Here is a link that shows how to check that:

https://www.2carpros.com/articles/how-to-test-a-catalytic-converter

Also, a timing issue can be the cause which would result in low compression and ignition timing issues. With that, I would recommend testing engine compression.

https://www.2carpros.com/articles/how-to-test-engine-compression

As far as the tiny leak, make sure it isn't allowing unmetered air to enter the engine. That will cause at least a rough idle.

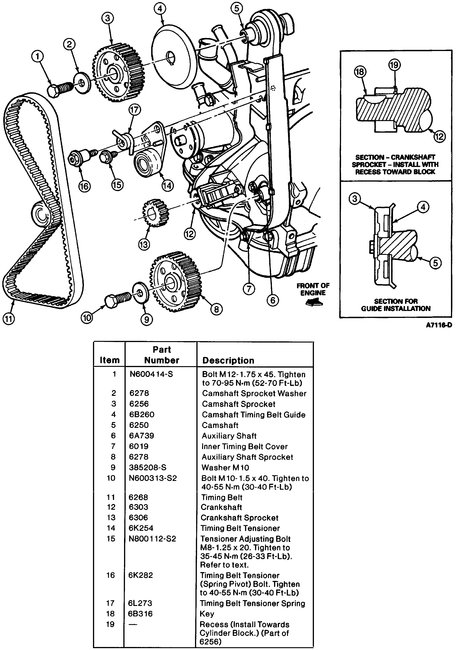

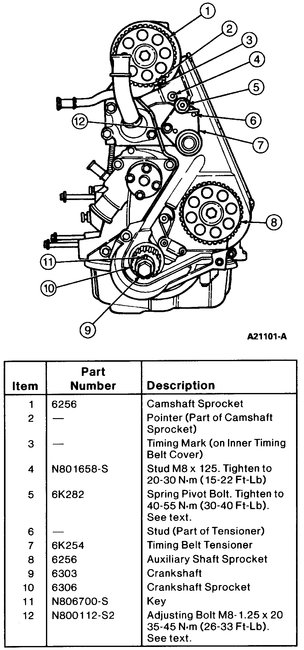

Now, in addition to all of this, I am really questioning if the timing belt has jumped. Here are directions for installing the timing belt. I'm adding them in case you want to check to make sure timing marks are correct. The attached pictures correlate with these directions.

INSTALLATION

Special Service Tool Required:

Camshaft Belt Tension Adjusting Tool T74P-6254-A

Synchronizer Positioner T93P-12200-A

picture 1

1. Remove one spark plug from each cylinder.

2. If not done:

a. Loosen tensioner adjusting bolt.

b. Using Camshaft Belt Tension Adjusting Tool, PRY tensioner CLOCKWISE against spring tension as far as possible.

c. Tighten adjusting bolt to hold tensioner in RELEASED position.

3. Align crankshaft so number one piston is at Top Dead Center (TDC) as indicated by timing mark.

picture 2

4. Line up the camshaft sprocket timing mark with the inner timing belt cover timing mark, so that the key is pointing DOWN.

NOTE: On 49-State, and all Automatic Transmission vehicles, it is not necessary to align auxiliary shaft sprocket.

5. If vehicle is California Emissions Certified with a Manual Transmission:

a. Install Synchronizer Positioner into synchronizer.

b. ROTATE auxiliary shaft sprocket until the synchronizer shutter is against the stop, and the notch of the tool engages the notch of the synchronizer bowl.

6. Install timing belt over crankshaft sprocket. Then, proceeding COUNTER-CLOCKWISE, over auxiliary shaft sprocket and camshaft sprocket.

7. Loosen tensioner adjusting bolt allowing tensioner pulley to press against timing belt.

8. Remove tool from synchronizer.

NOTE: When performing the following step, DO NOT ROTATE crankshaft COUNTER-CLOCKWISE as timing belt may jump a cog, putting camshaft or auxiliary shaft out of time.

9. ROTATE crankshaft two revolutions CLOCKWISE.

10. Bring crankshaft slowly, without stopping, to number one cylinder firing position (keyway directly UP).

11. Recheck timing mark alignment. Repeat steps if timing marks are no longer properly aligned.

12. ROTATE tensioner assembly against bolt with torque wrench up to 41-45 N.m (30-33 ft-lb) and tighten adjusting bolt.

13. Tighten adjusting bolt to 35-45 N-m (26-33 ft-lb).

14. Tighten spring pivot bolt to 40-55 N.m (30-40 ft-lb).

15. Install the crankshaft belt guide.

16. Install the crankshaft position sensor onto the dowel pin and tighten the two longer bolts to 8-12 N.m (6-9 ft-lb).

17. Adjust crankshaft position sensor air gap.

18. Install outer timing belt cover.

19. Install spark plugs.

Let me know if any of this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Wednesday, July 29th, 2020 AT 11:26 AM

(Merged)