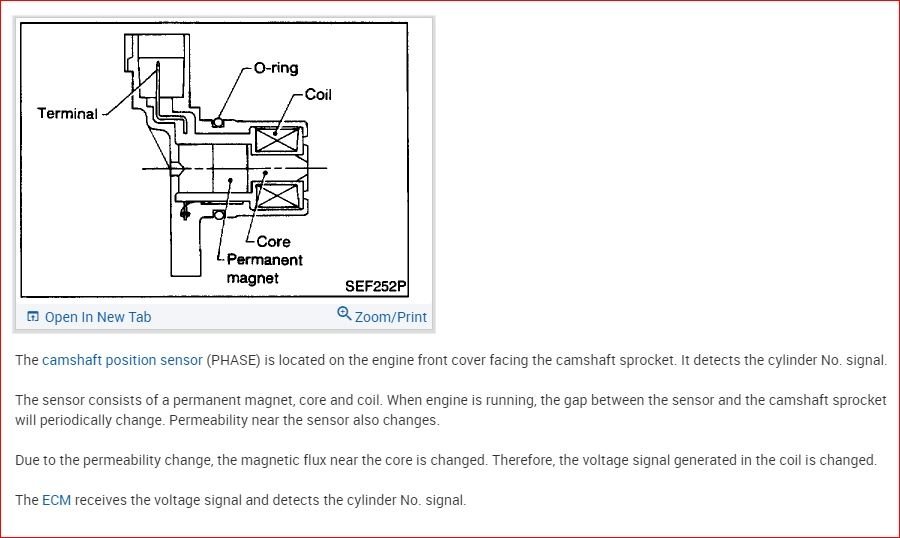

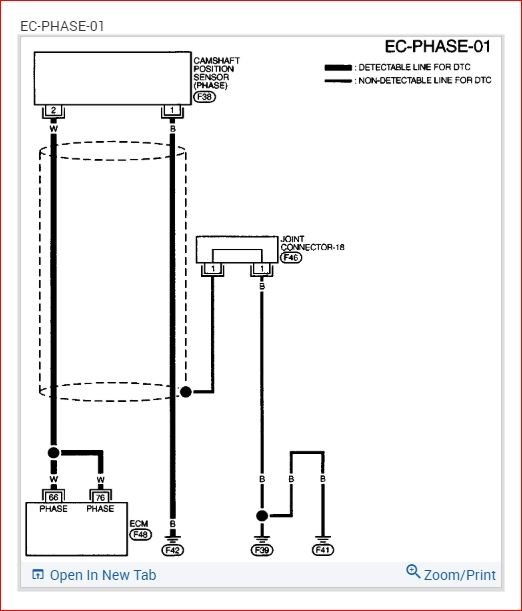

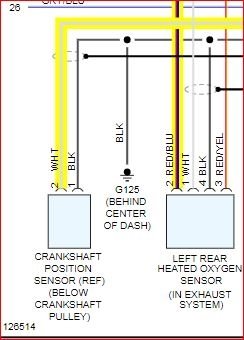

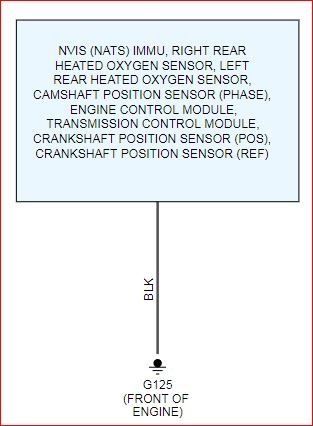

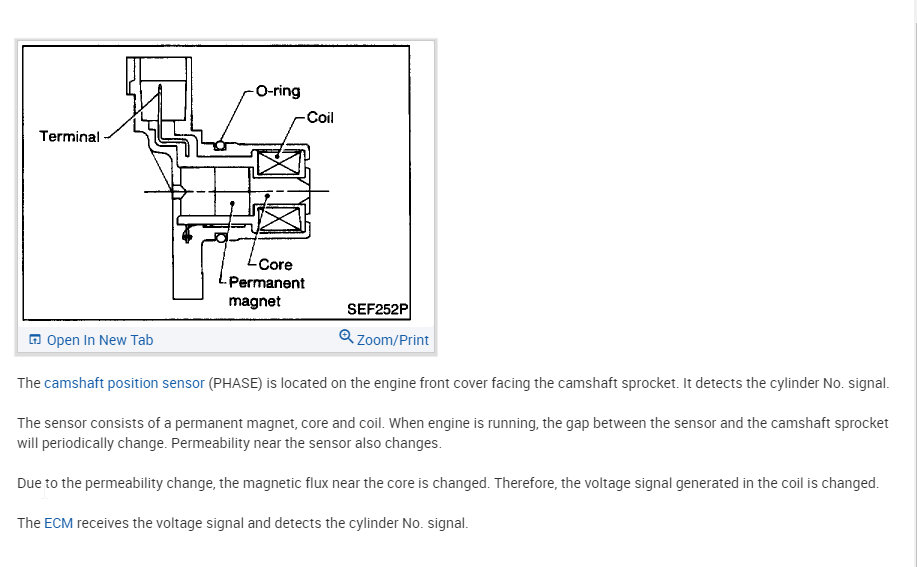

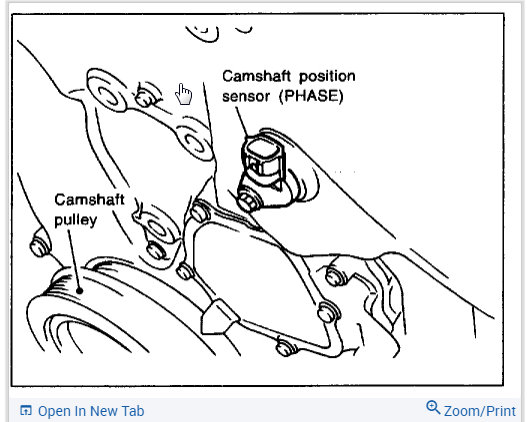

The timing being off I would not think would cause this. However, the cam sensor is responsible for detecting piston position. Attached is the component description. If the PCM is not getting a good signal from the cam sensor then it will not know when to fire the plugs.

This I think is the issue. If you have power, ground, and signal from the PCM at the coils then the PCM is able to fire the plug but it seems like it doesn't know when to fire the plug.

When you replaced the engine did you put the same engine back in? Did you swap over the cam sensor or did you use the one that came with the new engine (if it had one)? Also, if it was another 3.0L engine was it a used engine out of another car or a re-manufactured engine?

Have you checked to see if you have any fault codes? Lastly the cam sprocket that you put on, was it new or used? Did you check it for cracks or damage?

Images (Click to make bigger)

Sunday, May 26th, 2019 AT 3:45 PM