Dear CARADIODOC,

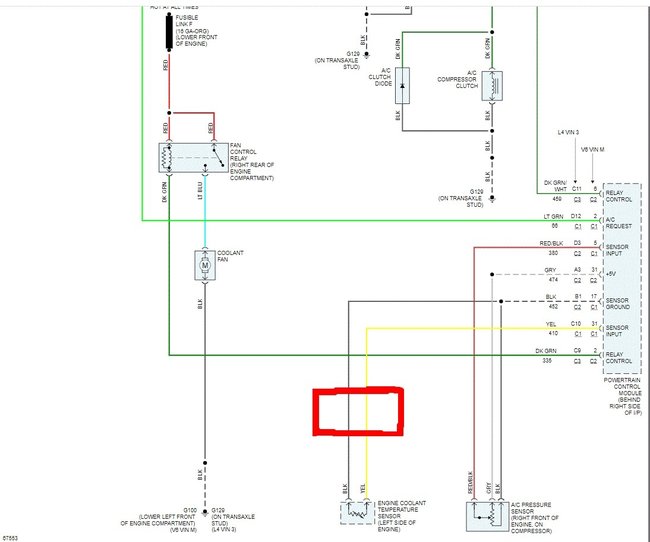

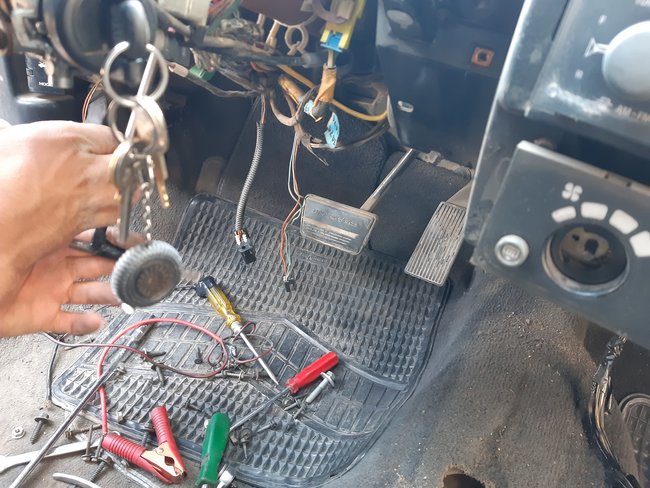

These are invaluable aids as far as I am needing any clue, I am extremely grateful for that. The wires within the harness coming from the 4 relays corner all the way around the rear of the engine and then to the front side had some terminated wires as one reckless electrician was dealing with an intermittent shutting down of the engine. The engine would stall all of a sudden as I am driving or even when warming up (stationary) in the garage. I tried all possible reasons and replaced all sensors in the intake manifold (including the crank position sensor, MAP, TPS and air flow sensor as they call it here) down to the fuel pressure regulator (valve) of the fuel line rack, nozzles along with their harness, ignition switch (both the mechanical one to the right of the steering wheel and the sophisticated black one at its rear protruding from the left side of the steering wheel), I even replaced the fuel pump relay control switch/engine oil pressure switch. I dismantled the whole thick harness and checked for any short circuit or discontinuity. The remaining issue is these (ECT sensor and sender), I am differentiating between the two terms: sensor and sender as it was in earlier threads where I inquired about the wiring of the engine 2 months ago. By (sensor) I be referring to the unit that provides the readings of the temperature gauge in the ip whereas by (sender ) I be referring to the unit that provides coolant temperature info to the PCM.

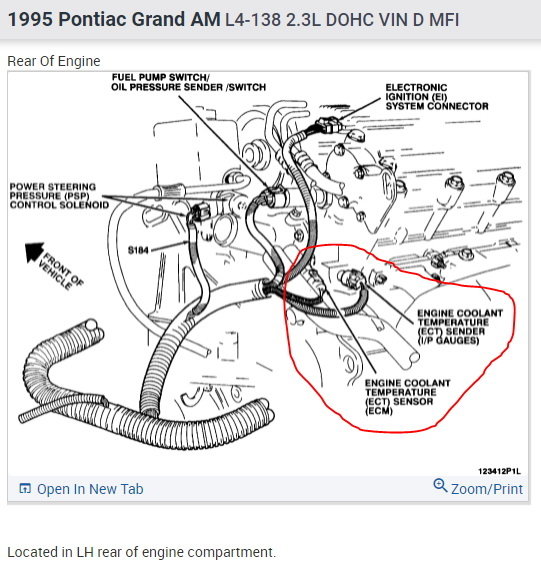

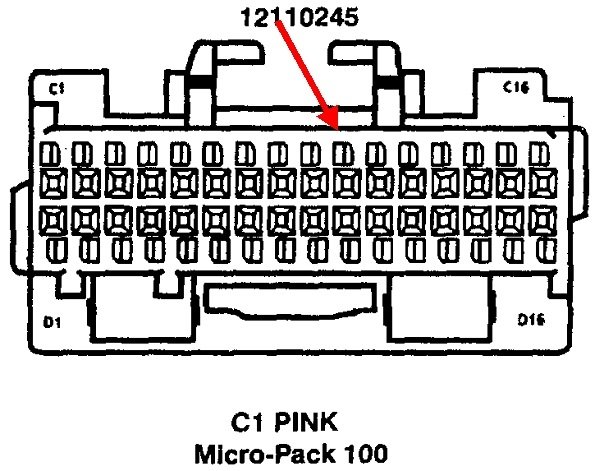

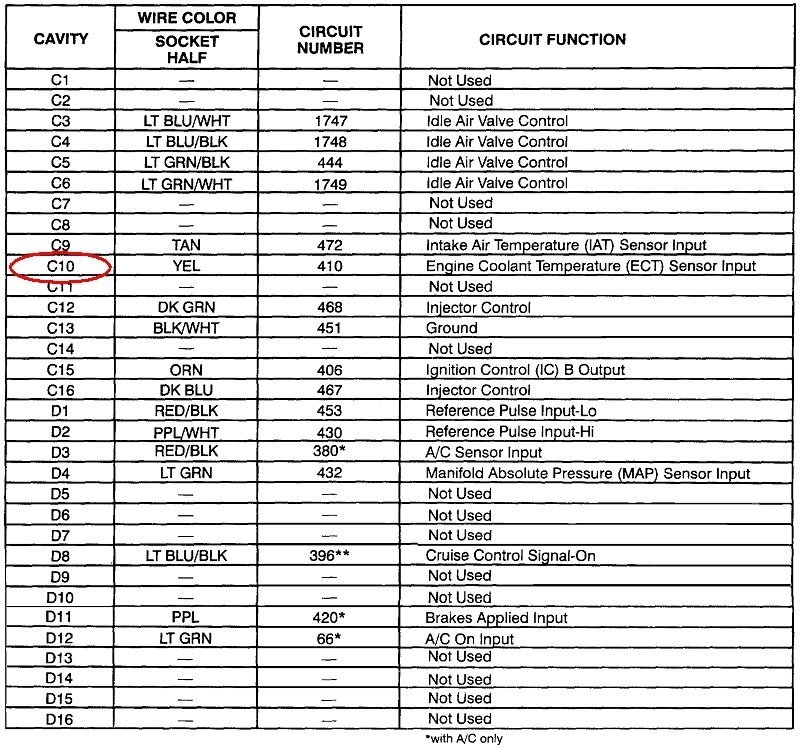

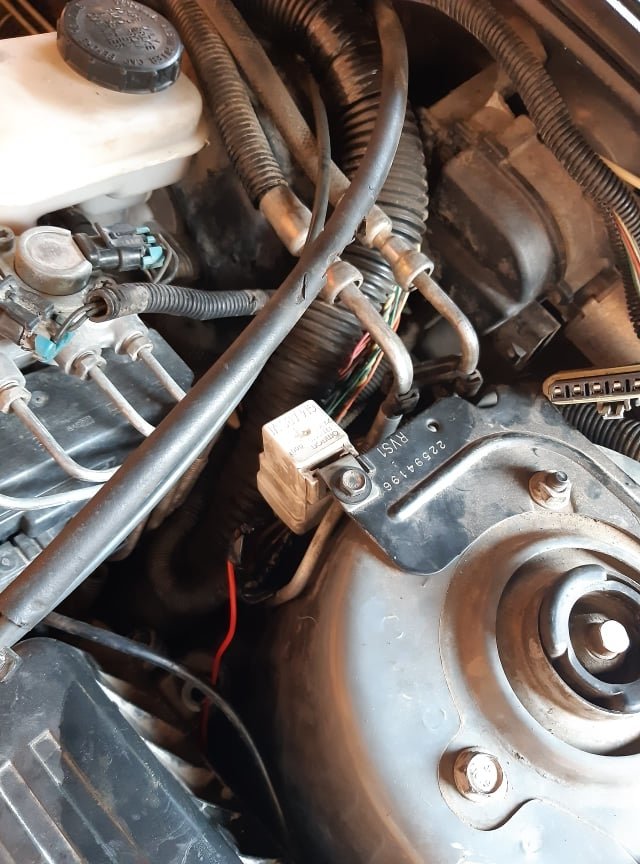

As you can see from the first few shots, I have 3 units all as sensors within the same aluminum body/housing of the coolant thermostat valve( referring to the respective numbers highlighting each unit as in the fourth attachment) :

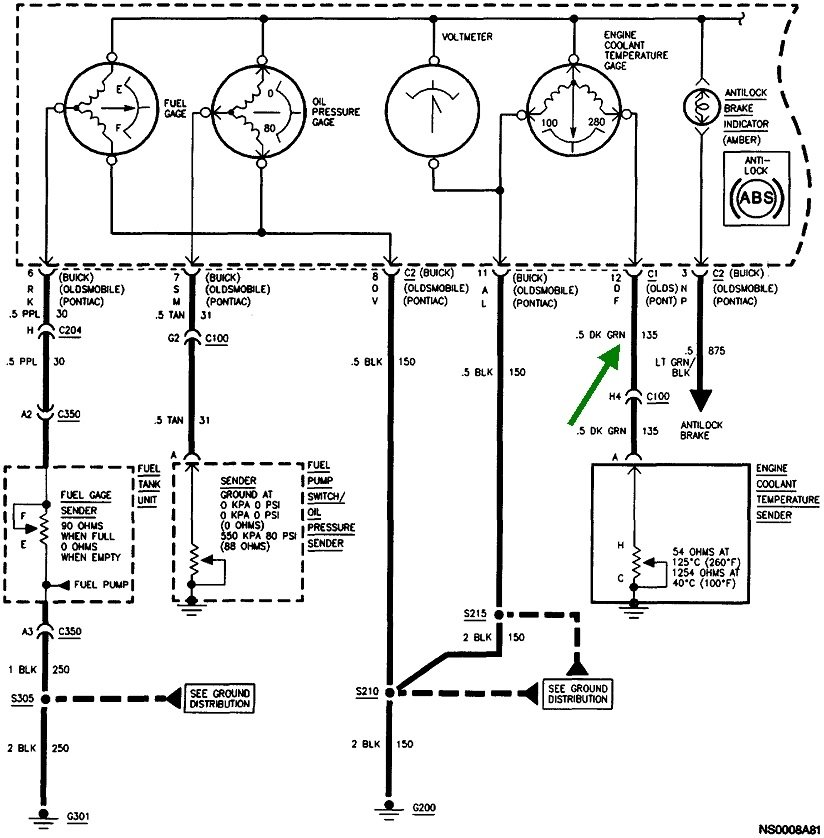

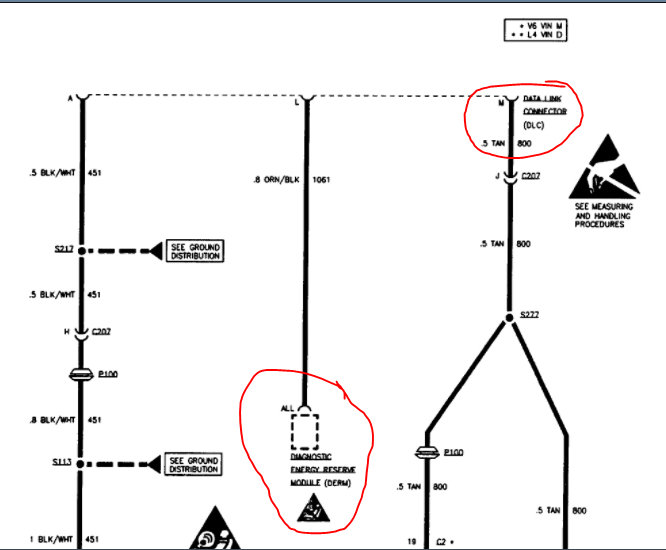

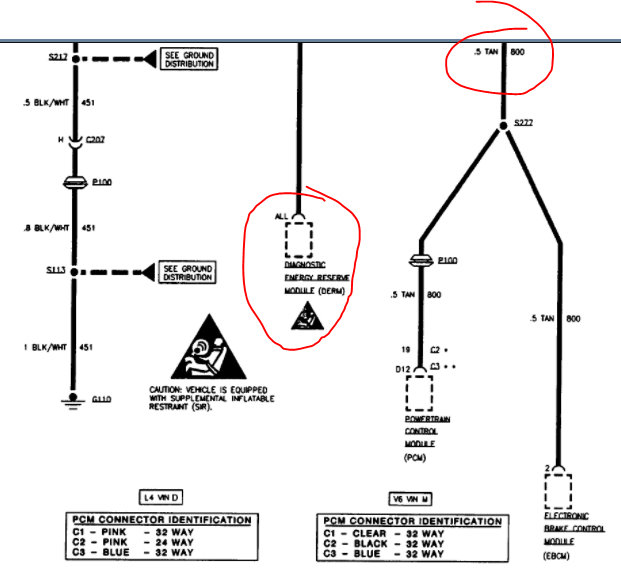

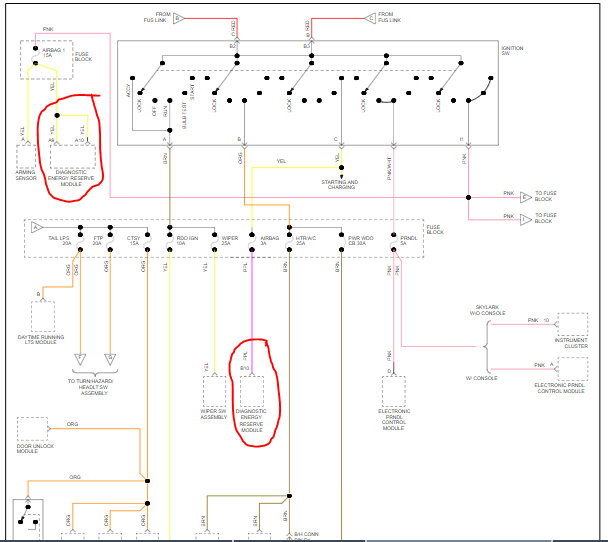

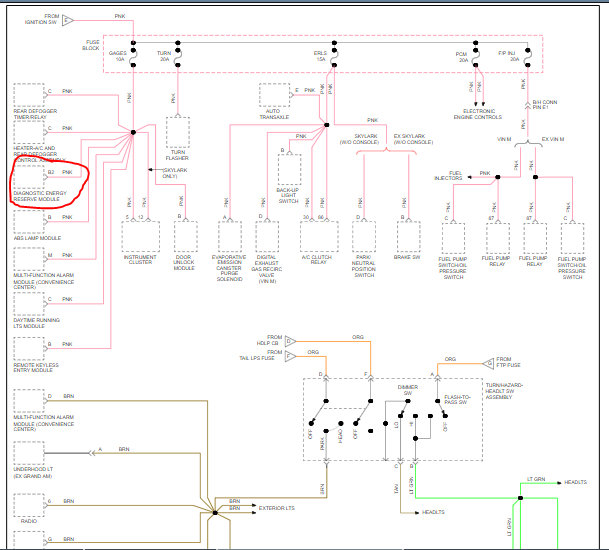

1. One unit supposed to be the sensor according to the schematic drawing attached here ( marked with a red surrounding shape) (and given a number 1 in the fourth attachment too), its connector is a rather large white one.

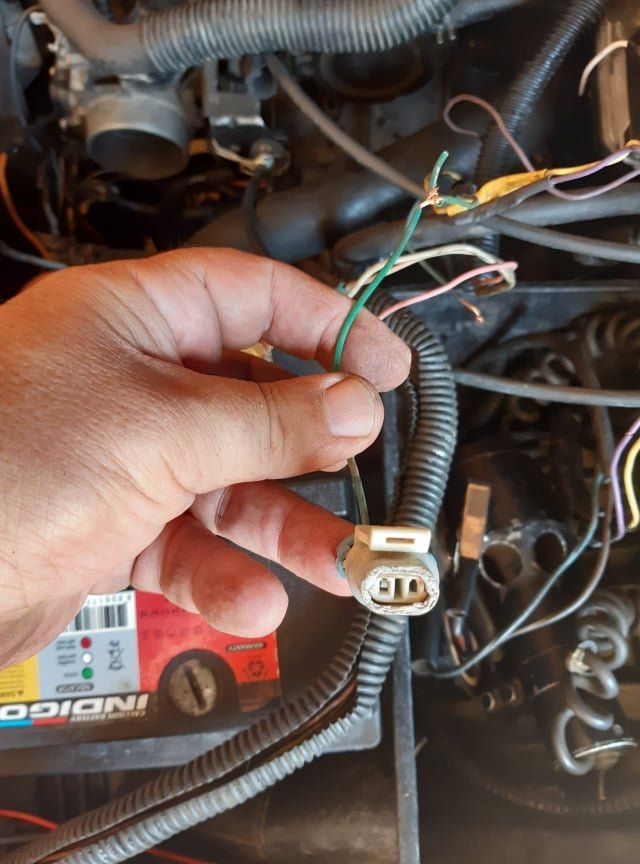

2. Right below that( or to the right side of it as in the fourth attachment); there is another one having a connector female part that is broken off ( but the 2 metal pins are still protruding out as you can clearly see), I gave it the number 2 in the fourth attachment. This sensor ( or may be sender) unit is anonymous to me since it is an obsolete part of the engine I have: which wires and colors should be attached to it and what does it serve?

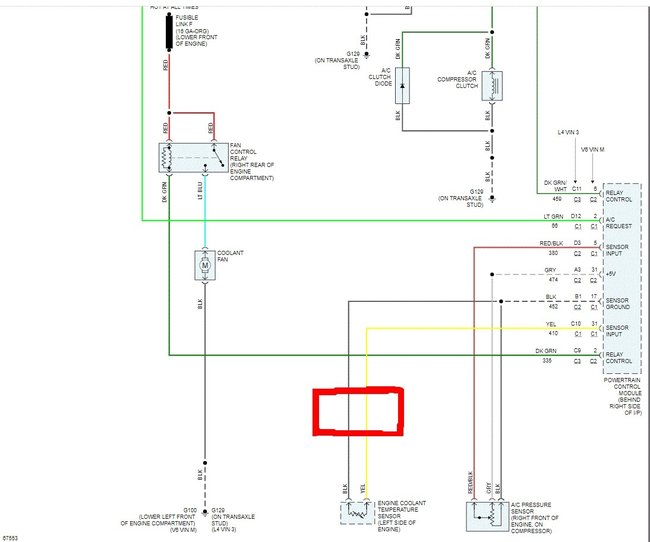

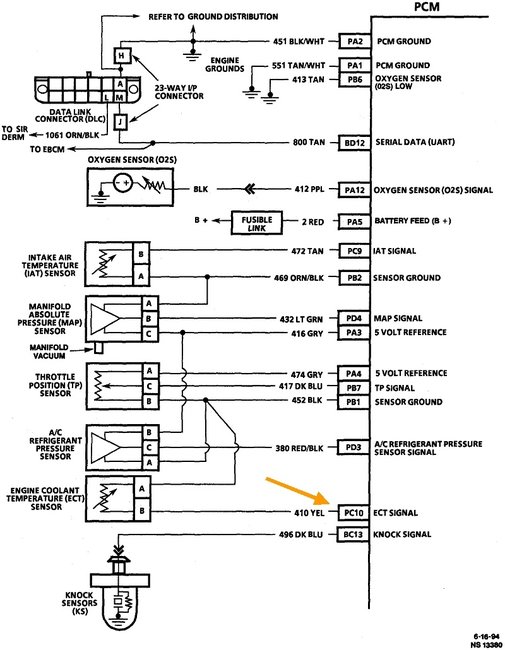

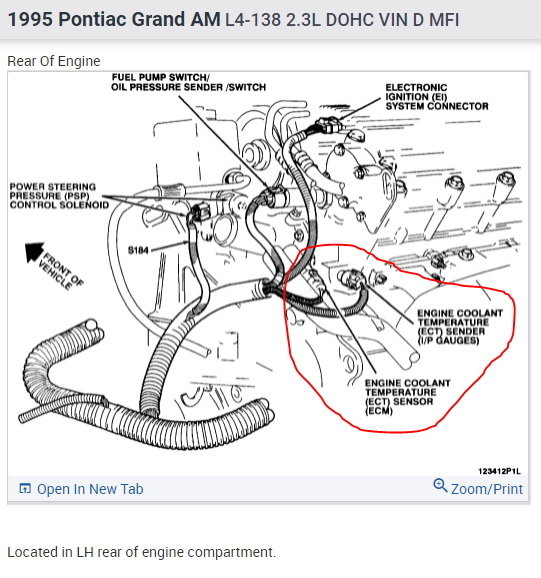

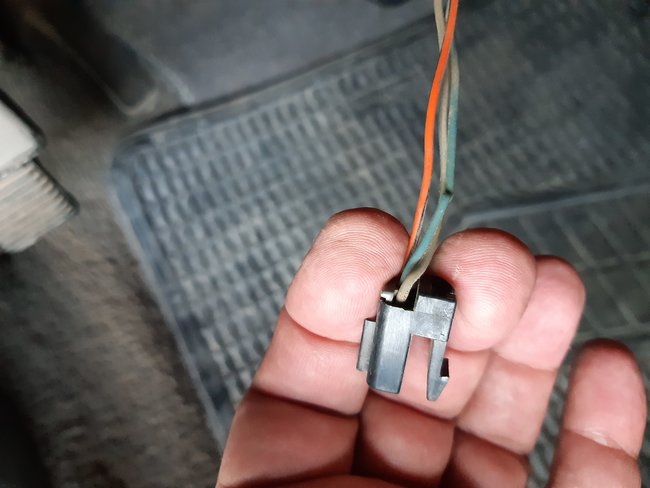

3. To the left side of both sensors mentioned above here( points 1 and 2) there is what I may call as ( the ECT sensor) that is supposed to relay the temperature to the ip/ temp gauge. Somehow; your generous reply mentioned a single wire only for this unit but I have 2 instead: a black and a yellow ones. Currently, its connector( a rather small black connector if compared with the white ones in points 1 and 2 above here which carries two wires right from the same harness: a black wire and a yellow wire. These two wires conform to the information given in the second attachment here: yellow and black wires leading to pins ( 31 c1 and 17 c1 of the PCM, respectively), they had been verified to be the right wires for this sensor since the gauge in the instruments panel works normally with them used like this.

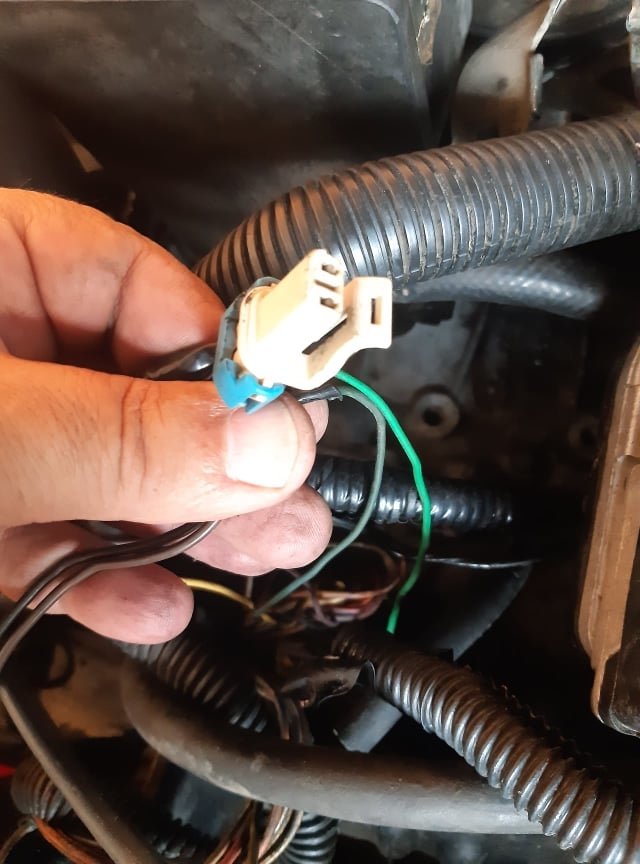

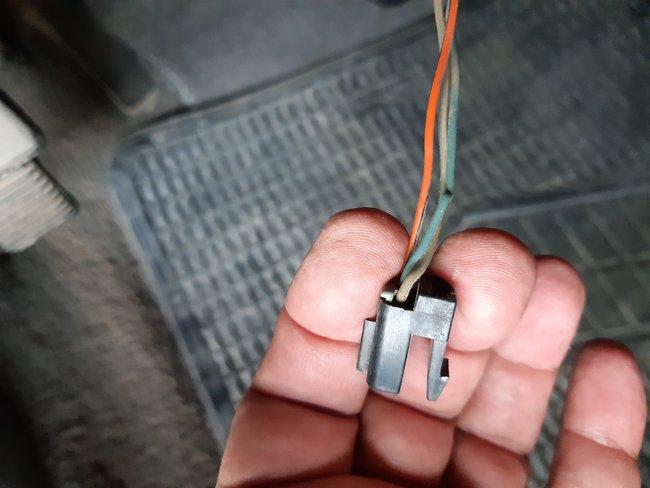

So the puzzling thing is the ect sender unit: the third attachment here shows the current available connector and wires: a green and a blue couple of wires: I need to know the followings please:

I. Should I use this connector as it is to make the sender unit work normally and be communicating with the PCM in the right manner? I mean with the two wires or is it the green wire only that should be there?

Ii. Which pins (in any one of the pcm c1 or c2 pink connectors) are relevant to these two wires( green and blue)?

Iii. How to test this circuit( of the sender) in may be the same way you have just kindly elaborated as per the sensor unit?

I appreciate your patience with my case, I am desperate to finish this problem that did cost me a lot so far and pushed me to the verge of total despair.

Images (Click to make bigger)

Wednesday, July 28th, 2021 AT 7:22 PM