Friday, December 12th, 2025 AT 2:38 PM

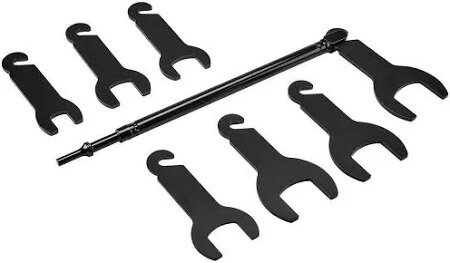

I'm having a very very hard time getting the fan clutch nut off of the pulley. Some people say that you turn it clockwise and some people say you turn it counterclockwise but the way the fan blades look, it looks like you turn it clockwise to loosen it. I cannot for the life of me loosen this nut. I cannot find a pulling range at any parts store. This pulley has four holes in it and supposedly it fits an M8 so you can use a long screwdriver or a pry bar to hold it while you try to turn the nut. I've also tried to put some heat to the nut and still didn't work. I've tapped my wrench with a hammer to try to shock it but nothing works. I even tried turning it counterclockwise and it still won't budge. I cannot hold the pulley well enough to even try to make a real effort to turn the nut. Strap wrenches doesn't work either. Well the Robert ones don't. My question is, it is reverse thread and you go clockwise to loosen it right? Also do you have any ideas on how I can get this fan clutch nut off? I'm changing the water pump